Content

U.S. Conformal Coatings Market Size and Growth 2025 to 2034

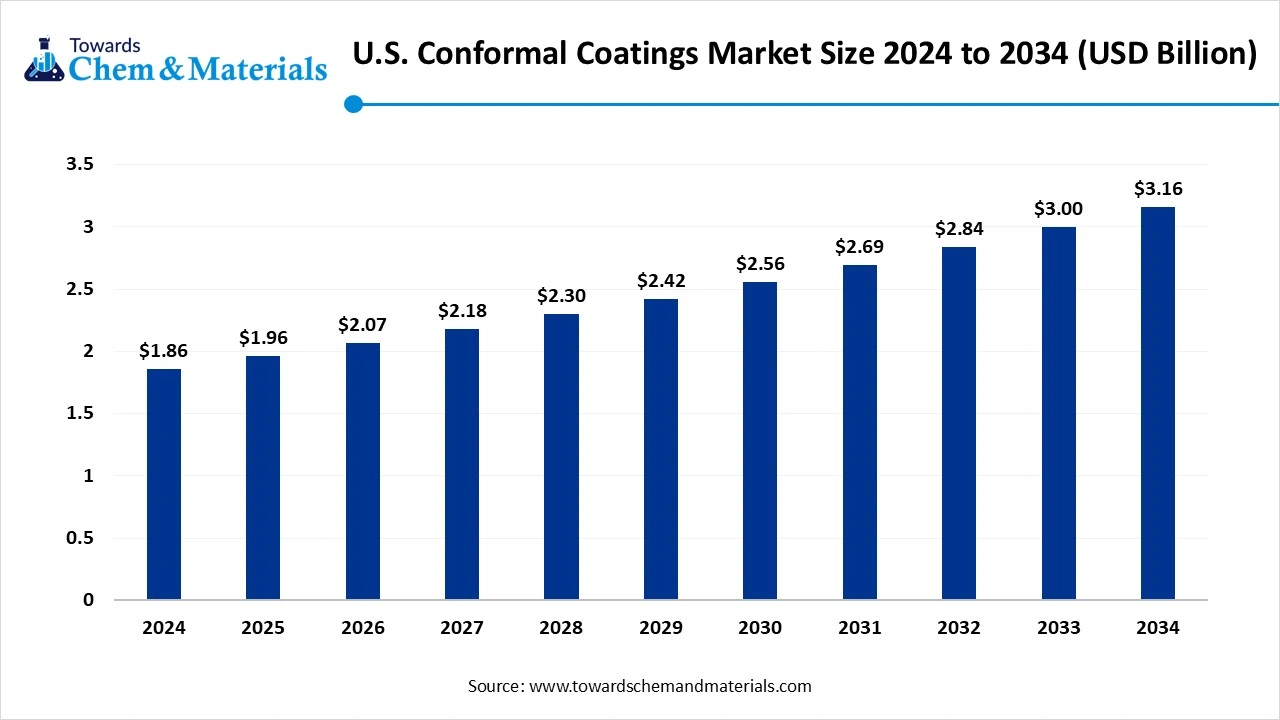

The U.S. conformal coatings market size was valued at USD 1.86 billion in 2024, grew to USD 1.96 billion in 2025, and is expected to hit around USD 3.16 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.44% over the forecast period from 2025 to 2034.

The growing need for protection in the various consumer industries is the key factor driving market growth. Also, increasing emphasis on 5G infrastructure and Internet of Things (IoT), coupled with the rapid advancements in coating materials, can fuel market growth further.

Key Takeaways

- By type, the acrylic segment dominated the market with a 28% share in 2024. The dominance of the segment can be attributed to the growing demand for reliable performance in new applications.

- By type, the parylene segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be credited to the growing demand for autonomous and electric vehicles.

- By formulation, the solvent-borne segment held a 45% market share in 2024. The dominance of the segment can be linked to the rising demand to protect electronics in major sectors.

- By formulation, the waterborne segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be driven by stringent environmental regulations necessitating low-VOC coatings.

- By application method, the automated spray coating segment dominated the market by holding a 40% share in 2024. The dominance of the segment is owed to the rising adoption of industrial automation and the need for cost-effective methods.

- By application method, the automated selective coating segment is expected to grow at the fastest CAGR during the projected period. The growth of the segment is due to the rapid miniaturization and growing complexity of electronics.

- By end-use industry, the consumer electronics segment held a 30% market share in 2024. The dominance of the segment can be attributed to the growing demand for more complex and smaller electronic devices.

- By end-use industry, the automotive electronics segment is expected to grow at the fastest CAGR during the study period. The growth of the segment can be credited to the growing adoption of electric vehicles (EVs).

- By distribution channel, the distributors/resellers segment dominated the market by holding a 50% share in 2024. The dominance of the segment can be linked to the growing product demand from high-tech sectors.

- By distribution channel, the online / E-commerce segment is expected to grow at the fastest CAGR during the forecast period. The growth of the segment can be driven by the growing demand for more complex and smaller electronic devices.

What are Conformal Coatings?

The market involves the sales of specialty film and liquid coatings designed to safeguard electronic assemblies and PCBs from environmental hazards such as chemicals, dust, moisture, and mechanical stress. These materials, like epoxies, silicones, acrylics, and urethanes, are improving the longevity and reliability in sectors such as consumer electronics, aerospace, medical devices, and automotive. Advancements in materials and other application techniques are creating new performance benchmarks.

What Are the Key Trends Influencing the U.S. Conformal Coatings Market?

The rapid expansion of the electronic industry is a major driver for the market. The rapid proliferation of electronic devices, from industrial machinery to smartphones and wearables, requires the application of conformal coatings. These coatings give a shield to these devices, protecting critical circuitry from various environmental factors.

Rapid innovations in conformal coatings are the latest trend in the market, shaping a positive market trajectory. The creation of more flexible, resilient, and sustainable formulations can improve resistance to hostile conditions such as chemicals, intense temperatures, and dampness in different devices and appliances.

The strong defense and aerospace industries in the U.S. are also major drivers of conformal coating demand, particularly for high-resistance and durable coatings. Also, increasing demand for coatings with enhanced corrosion resistance and overall durability can contribute to the market expansion further.

Market Opportunity

Growing Demand for Smart Wearables

The surge in demand for smart wearables and IoT devices is a major factor creating lucrative opportunities in the market. Communication devices and consumer electronics are crucial application areas for conformal coating. Furthermore, the need for conformal coating in consumer electronics like smart devices will increase the demand for smartphones. To raise the longevity of this device, market players are using cutting-edge coating technology solutions.

Market Challenge

Application Complexities

Proper coatings necessitate skilled labor, specialized equipment, and careful control of environmental factors such as temperature and humidity to avoid defects like cracks, bubbles, or even layers, which can sometimes be challenging. Moreover, dust, oil, and fabrication residues can substantially weaken the coating's efficiency and cause failures like peeling, hindering market growth further.

Country Insight

U.S. Conformal Coatings Market Trends

The west region dominated the market by holding a 35% share in 2024 and is expected to grow at the fastest CAGR over the forecast period. The growth of the region can be attributed to the growing demand for innovative automotive electronics in electric vehicles, along with the rising need for corrosion-resistant and durable coatings. In addition, ongoing investment in infrastructure projects like 5G will contribute to the regional growth soon.

Segmental Insight

Type Insight

Which Type Segment Dominated the U.S. Conformal Coatings Market in 2024?

The acrylic segment dominated the market with largest share in 2024. The dominance of the segment can be attributed to the growing demand for reliable performance in new applications such as wireless devices and electric vehicles. Additionally, acrylics offer a strong adhesion to different substrates and crucial dielectric properties for electrical insulation, which are necessary for protecting electronic components.

The parylene segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be credited to the growing demand for autonomous and electric vehicles, coupled with the rising need for safe protection in the defense, aerospace, and medical sectors. Parylene is applied as a vapor, allowing for conformal, uniform coverage on complex 3D shapes with exceptional thickness control and precision.

Formulation Insight

Why Solvent-Borne Segment dominated the U.S. Conformal Coatings Market in 2024?

The solvent-borne segment held largest market share in 2024. The dominance of the segment can be linked to the rising demand to protect electronics in major sectors such as aerospace, automotive, and consumer electronics. Also, rising complexity in miniaturization in electronic components requires effective protective solutions, which can be provided by solvent-borne coatings.

The waterborne segment is expected to grow at the fastest CAGR over the forecast period. The growth of the segment can be driven by stringent environmental regulations necessitating low-VOC coatings, along with the growing need for sustainable and eco-friendly products. Also, the U.S. manufacturers are investing in R&D of advanced coating solutions to fulfill environmental and performance demands.

Application Method Insight

How Much Share Did the Automated Spray Coating Segment Held in 2024?

The automated spray coating segment dominated the market in 2024. The dominance of the segment is owed to the rising adoption of industrial automation and the need for cost-effective and faster application methods to meet manufacturing demands. Furthermore, an automated system can reduce waste, optimise resource allocation, and lower overall manufacturing costs.

The automated selective coating segment is expected to grow at the fastest CAGR during the projected period.

The growth of the segment is due to the rapid miniaturization and growing complexity of electronics, which fuels demand for automated and precise applications. Moreover, selective coating technologies using process controls and robotic application provide superior precision, allowing thinner coatings at high densities.

End-Use Industry Insight

Which End-use Industry Segment Dominated the U.S. Conformal Coatings Market in 2024?

The consumer electronics segment held the largest market share in 2024. The dominance of the segment can be attributed to the growing demand for more complex, smaller electronic devices, which need improved protection against environmental stressors such as dust and moisture. In addition, the extensive adoption of wireless connectivity and the growth of the Internet of Things (IoT) can result in more complicated electronic systems.

The automotive electronics segment is expected to grow at the fastest CAGR during the study period. The growth of the segment can be credited to the growing adoption of electric vehicles (EVs) and the need for strong protection against automotive environments such as temperature extremes. Furthermore, the surge in EV adoption requires high-voltage components to ensure durability and safety.

Distribution Channel Insight

Which Distribution Channel Segment Dominated the U.S. Conformal Coatings Market in 2024?

The distributors/resellers segment dominated the market in 2024. The dominance of the segment can be linked to the growing product demand from high-tech sectors such as automotive, consumer electronics, and aerospace. Furthermore, the presence of stringent quality standards and regulatory compliance, particularly in sectors such as healthcare and aerospace, highlights the importance of protective coatings.

The online / E-commerce segment is expected to grow at the fastest CAGR during the forecast period. The growth of the segment can be driven by growing demand for more complex and smaller electronic devices, which leads to more online sales of protective coatings. Furthermore, online channels allow market players and distributors to reach a wider consumer base beyond their conventional geographical limitations.

U.S. Conformal Coatings Market Value Chain Analysis

- Feedstock Procurement: It is the process of acquiring the primary raw materials, polymers, and solvents, which are used to produce conformal coatings.

- Chemical Synthesis and Processing: This process refers to the development of innovative material formulations with the cutting-edge production techniques used to manufacture, apply, and cure conformal coatings.

- Packaging and Labelling: It refers to the variety of containers used for coatings, with the important regulatory information displayed on them.

- Regulatory Compliance and Safety Monitoring: These are the crucial aspects of the market. These regulations ensure environmental responsibility, product safety, and worker well-being.

Recent Developments

- In July 2024, Dow introduced a DOWSILCC-8000 Series dual and UV moisture cure conformal coatings, a type of solventless silicone coating that offers strong protection for electronic devices in renewable energy and other applications.(Source: www.indianchemicalnews.com)

U.S. Conformal Coatings Market Top Companies

- Dow

- Henkel

- 3M

- HumiSeal (Element Solutions)

- H.B. Fuller

- PPG Industries

- Parker Hannifin (Parker Chomerics)

- LORD Corporation

- Chase Corporation

- MG Chemicals

- Electrolube

- Shin-Etsu Chemical

- Momentive Performance Materials

- Aremco Products

- Panacol-Elosol

- Arkema (Sartomer)

- Eastman Chemical Company

- Solvay

- Wacker Chemie

- The Chemours Company

Segments Covered

By Type (Resin Chemistry)

- Acrylic

- Epoxy

- Urethane / Polyurethane

- Silicone

- Parylene

- Fluoropolymer

- Other Specialty Resins (hybrids, siloxanes, polyimides)

By Formulation (Carrier System)

- Solvent-borne

- Waterborne

- 100% Solids / Solventless

- UV / EB-curable

By Application Method

- Automated Selective Coating (robotic)

- Automated Spray Coating

- Manual Spray Coating

- Dip Coating

- Brush / Pen Coating

- Vacuum Deposition (Parylene)

By End-use Industry

- Consumer Electronics

- Automotive Electronics

- Industrial Electronics

- Aerospace & Defense

- Medical Devices

- Telecommunications & Networking

- Renewable Energy & Power Electronics

- Lighting & LEDs

- IoT & Smart Sensors

By Distribution Channel

- Direct Sales

- Distributors / Resellers

- Online / E-commerce

- Contract Coating Service Providers

List of Figures

- Figure 1 U.S. Conformal Coatings Market Size (USD 1.86 Billion with CAGR 5.44%), 2024–2034

- Figure 2 U.S. Conformal Coatings Market by Type (Acrylic 28%, Epoxy 18%, Urethane / Polyurethane 14%, Silicone 12%, Parylene 10%, Fluoropolymer 8%, Other Specialty Resins 10%), 2024

- Figure 3 U.S. Conformal Coatings Market by Formulation (Solvent-borne 45%, Waterborne 20%, 100% Solids / Solventless 18%, UV / EB-curable 17%), 2024

- Figure 4 U.S. Conformal Coatings Market by Application Method (Automated Spray Coating 40%, Automated Selective Coating 20%, Manual Spray Coating 15%, Dip Coating 10%, Brush / Pen Coating 8%, Vacuum Deposition (Parylene) 7%), 2024

- Figure 5 U.S. Conformal Coatings Market by End-use Industry (Consumer Electronics 30%, Automotive Electronics 20%, Industrial Electronics 15%, Aerospace & Defense 12%, Medical Devices 8%, Telecommunications & Networking 6%, Renewable Energy & Power Electronics 5%, Lighting & LEDs 2%, IoT & Smart Sensors 2%), 2024

- Figure 6 U.S. Conformal Coatings Market by Distribution Channel (Distributors / Resellers 50%, Direct Sales 25%, Online / E-commerce 15%, Contract Coating Service Providers 10%), 2024

- Figure 7 U.S. Conformal Coatings Market by Region (West 35%, Midwest 25%, South 20%, Northeast 20%), 2024

- Figure 8 U.S. Conformal Coatings Competitive Landscape: Market Share of Top 10 Companies, 2024

List of Tables

- Table 1 U.S. Conformal Coatings Market Size (USD 1.86 Billion with CAGR 5.44%) and Forecast (2024–2034)

- Table 2 U.S. Conformal Coatings Market by Type (Acrylic 28%, Epoxy 18%, Urethane / Polyurethane 14%, Silicone 12%, Parylene 10%, Fluoropolymer 8%, Other Specialty Resins 10%), 2024

- Table 3 U.S. Conformal Coatings Market by Formulation (Solvent-borne 45%, Waterborne 20%, 100% Solids / Solventless 18%, UV / EB-curable 17%), 2024

- Table 4 U.S. Conformal Coatings Market by Application Method (Automated Spray Coating 40%, Automated Selective Coating 20%, Manual Spray Coating 15%, Dip Coating 10%, Brush / Pen Coating 8%, Vacuum Deposition (Parylene) 7%), 2024

- Table 5 U.S. Conformal Coatings Market by End-use Industry (Consumer Electronics 30%, Automotive Electronics 20%, Industrial Electronics 15%, Aerospace & Defense 12%, Medical Devices 8%, Telecommunications & Networking 6%, Renewable Energy & Power Electronics 5%, Lighting & LEDs 2%, IoT & Smart Sensors 2%), 2024

- Table 6 U.S. Conformal Coatings Market by Distribution Channel (Distributors / Resellers 50%, Direct Sales 25%, Online / E-commerce 15%, Contract Coating Service Providers 10%), 2024

- Table 7 U.S. Conformal Coatings Market by Region (West 35%, Midwest 25%, South 20%, Northeast 20%), 2024

- Table 8 U.S. Conformal Coatings Market Trends, Drivers, Restraints, Opportunities, and Challenges

- Table 9 U.S. Conformal Coatings Market Value Chain Analysis (Feedstock Procurement, Chemical Synthesis & Processing, Packaging & Labelling, Regulatory Compliance & Safety Monitoring)

- Table 10 U.S. Conformal Coatings Competitive Benchmarking of Top Companies (Dow, Henkel, 3M, HumiSeal, H.B. Fuller, PPG, Parker Hannifin, LORD Corporation, Chase Corporation, MG Chemicals, Electrolube, Shin-Etsu, Momentive, Aremco, Panacol-Elosol, Arkema, Eastman, Solvay, Wacker Chemie, Chemours)