Content

Mechanical Recycling of Plastics Market Size, Share, Analysis and Forecast 2034

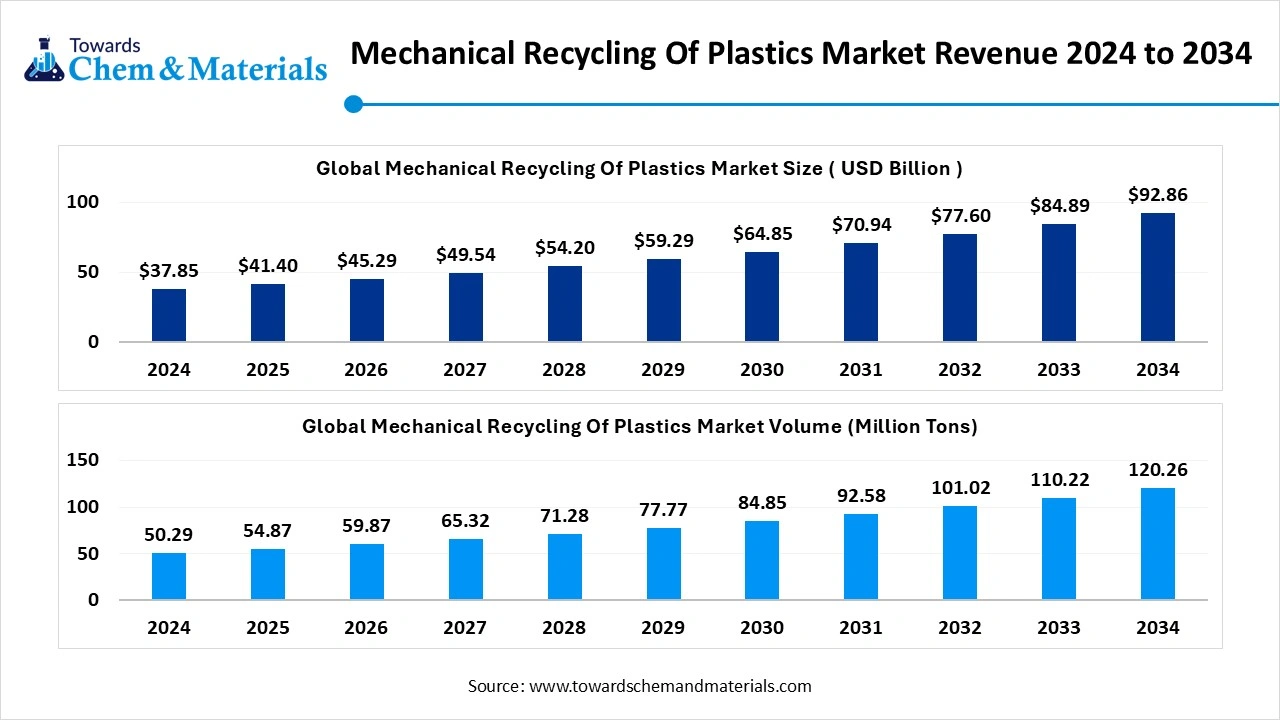

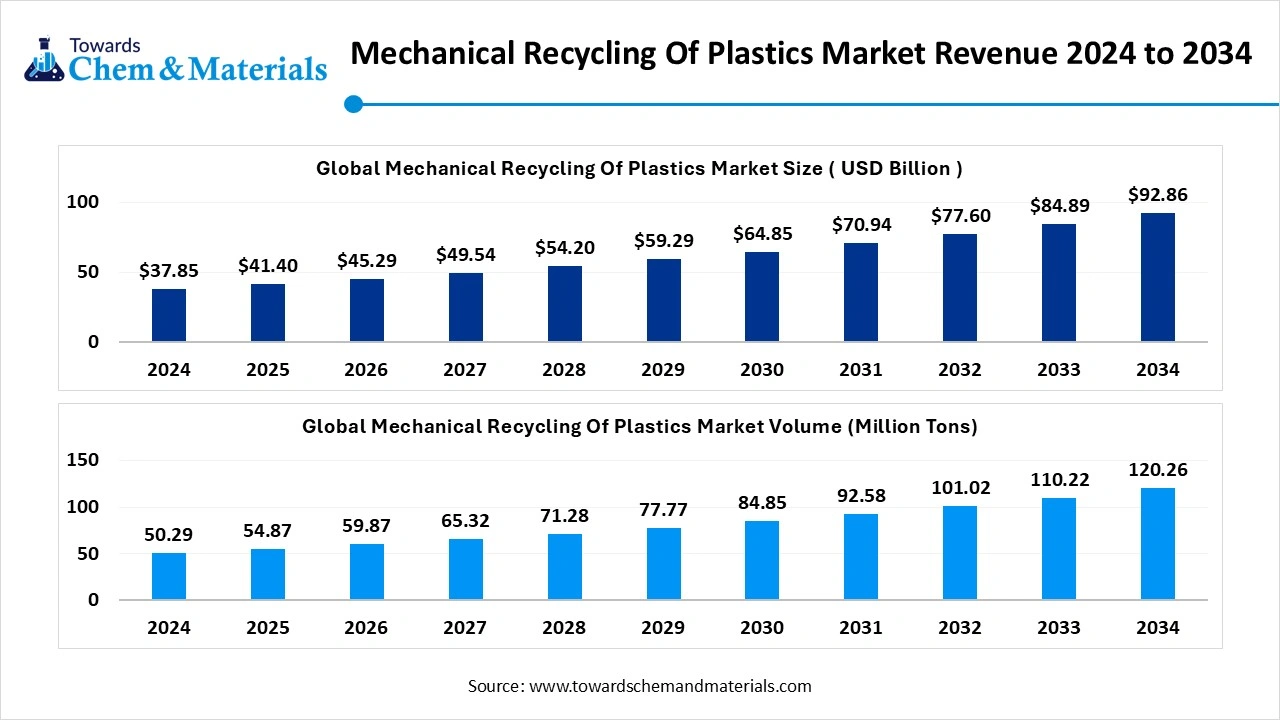

The global mechanical recycling of plastics market size was reached at USD 37.85 billion in 2024 and is expected to be worth around USD 92.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.39% over the forecast period 2025 to 2034. The growing plastic pollution, stringent regulations on plastic use, and growing production of automotive components drive market growth.

The global Mechanical Recycling Of Plastics Market is expected to reach a volume of approximately 54.87 million tons in 2025, with a forecasted increase to 120.26 million tons by 2034, growing at a CAGR of 9.11% from 2025 to 2034.

Key Takeaways

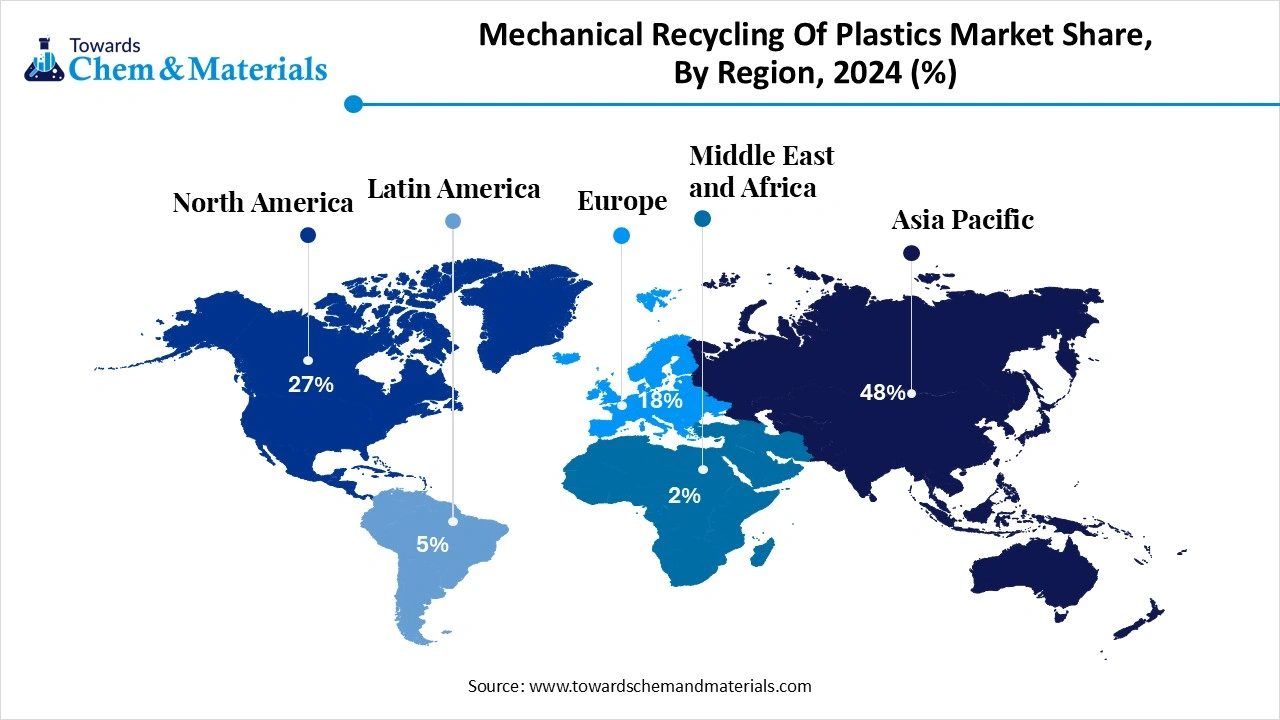

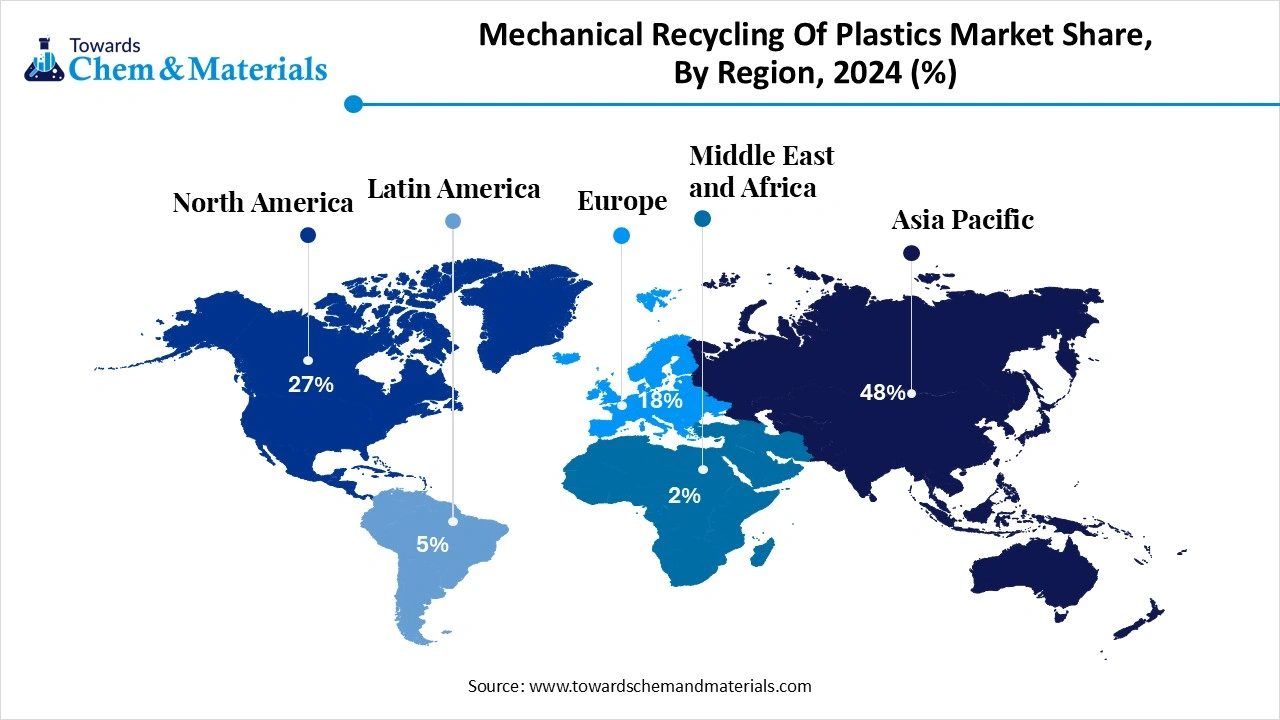

- Asia Pacific dominated the market and accounted for the largest revenue share of 48% in 2024.

- By recycling process, the extrusion segment accounted for the largest revenue share of 35% in 2024.

- By source of plastic waste, the post-consumer recycled segment held the largest revenue share of 60% in 2024.

- By polymer type, the polyethylene segment accounted for the largest revenue share of around 32% in 2024.

- By product form, the flakes segment dominated the market with a share of 76% in 2024

- By application, the packaging segment held the largest revenue share of 38% in 2024.

What is Mechanical Recycling of Plastics?

Mechanical recycling of plastics market growth is driven by stringent regulations on plastic waste, increasing production of construction materials, expansion of the packaging sector, technological advancements in mechanical recycling, and manufacturing of automotive components. The processing of plastic waste by collecting, sorting, shredding, melting, and reforming plastic waste into new products is called mechanical recycling of plastics. It offers benefits like extending the lifespan of products, energy efficiency, and minimizing greenhouse gas emissions.

What is the Process of Mechanical Recycling of Plastic?

| Process | Description | Equipment Used |

| Collection | The gathering of plastic like bottles, cups, & others from industrial and consumer sources. |

|

| Sorting | The segregation of collected plastic by quality, type (PP, PE, PET), and by color. |

|

| Shredding | The process of granulating sorted plastic into flakes and small pieces. |

|

| Washing | The process of removing contaminants like labels, dirt, and food residue from shredded plastic. |

|

| Drying | The process of removing residual moisture from flakes & small pieces. |

|

| Melting & Extrusion | The process of forming viscose liquid from dried flakes and cutting them into small pellets. |

|

| Compounding & Pelletizing | The process of forming homogenous and uniform pellets to manufacture products like containers, bottles, and fibers. |

|

Mechanical Recycling of Plastics Market Outlook:

- Industry Growth Overview: Between 2025 and 2034, the industry is expected to see accelerated growth in corporate commitments, regulatory pressure, regulatory initiatives, and consumer awareness about plastic pollution. Growth is being reinforced by growing environmental concerns, increasing awareness about plastic pollution, and a focus on the circular economy.

- Sustainability Trends: Sustainability is reshaping the mechanical recycling of plastics landscape by focusing on lowering reliance on virgin plastics and minimizing carbon footprint.

- Global Expansion: Leading players are expanding globally due to problems like climate change and increasing plastic waste. Companies like Dow, Indorama Ventures, Borealis, and TotalEnergies are expanding geographically. For instance, ALPLA is expanding across countries like Thailand, South Africa, and Romania.

Key Technological Shifts in the Mechanical Recycling of Plastics Market:

The mechanical recycling of plastics is observing a technological shift in advancing cleaning and enhancing sorting systems. The integration of Artificial Intelligence & robotics in sorting and optimal sorting helps in segregating various plastic types, lowering contamination, and enhancing the accuracy of sorting.

The advancements in cleaning, like super-cleaning & deodorization, help to remove odor, maintain extreme purity, and remove contamination from plastic. The advancements in sorting & cleaning technology support various applications like 3D printing, construction material development, and upcycling of products.

- For instance, the TOMRA company integrates AI for sorting of non-food-grade and food-grade plastics.

Trade Analysis of Mechanical Recycling of Plastics Market: Import & Export Statistics

- Germany exported 769 shipments of shredders.(Source: www.volza.com)

- India exported 3,989 shipments of plastic extruder machines.(Source: www.volza.com)

- France exported 2,236 shipments of plastic extruder machines.(Source: www.volza.com)

- China exported 353 shipments of plastic pelletizing machines.(Source: www.volza.com)

- Mexico exported 117,597 shipments of plastic waste.(Source: www.volza.com)

Mechanical Recycling of Plastics Market Value Chain Analysis

- Feedstock Procurement: The feedstock procurement involves the collection & sorting of plastic waste like polyethylene, PET, polypropylene & others into new products.

- Chemical Synthesis and Processing: The chemical synthesis & processing involve steps like collection of plastic, sorting, washing, drying, grinding into small fragments, melting, and pelletizing.

- Quality Testing and Certification: The quality testing evaluates conditions like density measurement, impact testing, melt flow index, moisture analysis, tensile testing, and certifications like ISCC Plus and RecyClass Recycling Process Certification.

Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 41.40 Billion |

| Expected Size by 2034 | USD 92.86 Billion |

| Growth Rate from 2025 to 2034 | CAGR 9.39% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Recycling Process, By Source of Plastic Waste, By Polymer Type, By Product Form, By Application, By Region |

| Key Companies Profiled | EREMA Group, Polystar Machinery Co., Ltd., Vecoplan AG, Herbold Meckesheim GmbH, KOWIN Plastic Machinery Co., Ltd., Starlinger & Co. GmbH, B+B Anlagenbau GmbH, ASG Recycling Machinery, Pluto Intero, Archana Extrusion Machinery Mfg., Sorema S.p.A., Doll Plast S.r.l., Plasmac S.r.l., Next Generation Recyclingmaschinen GmbH, Moretto S.p.A. |

Market Opportunity

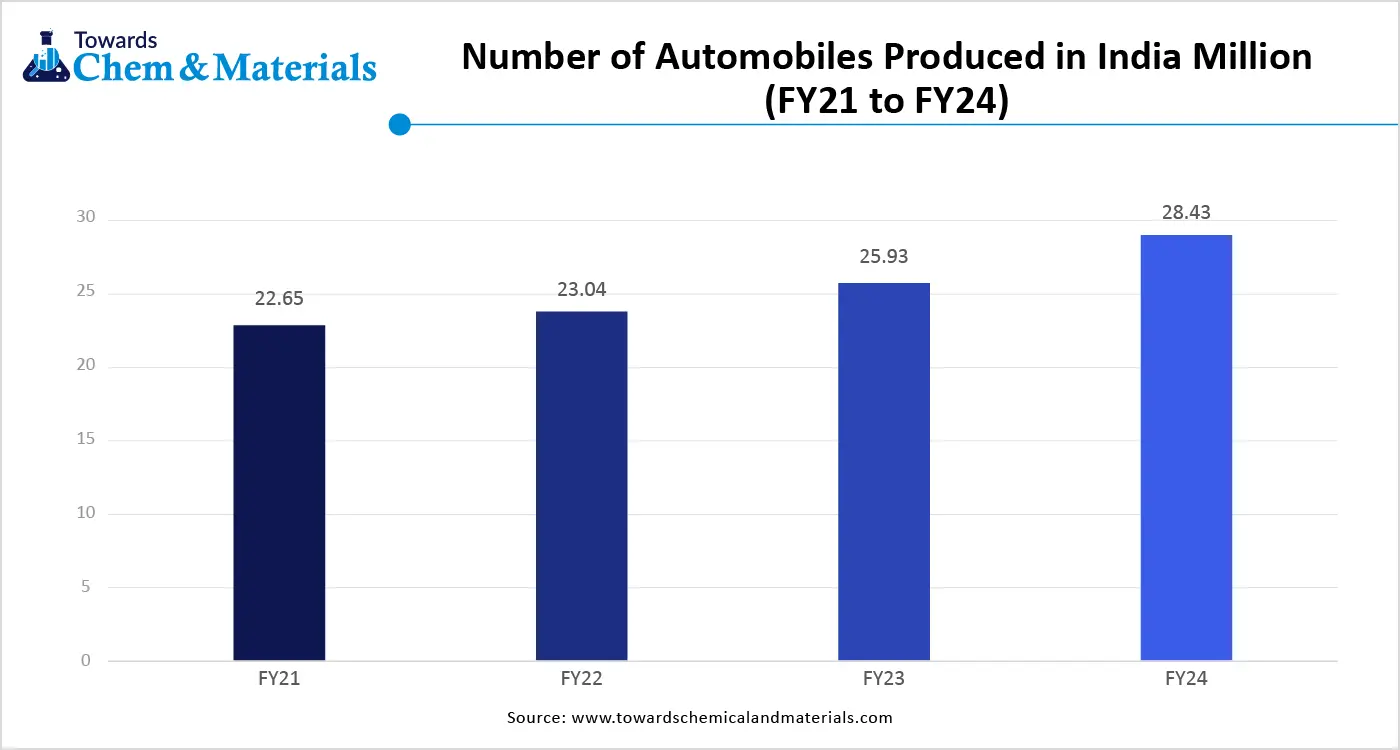

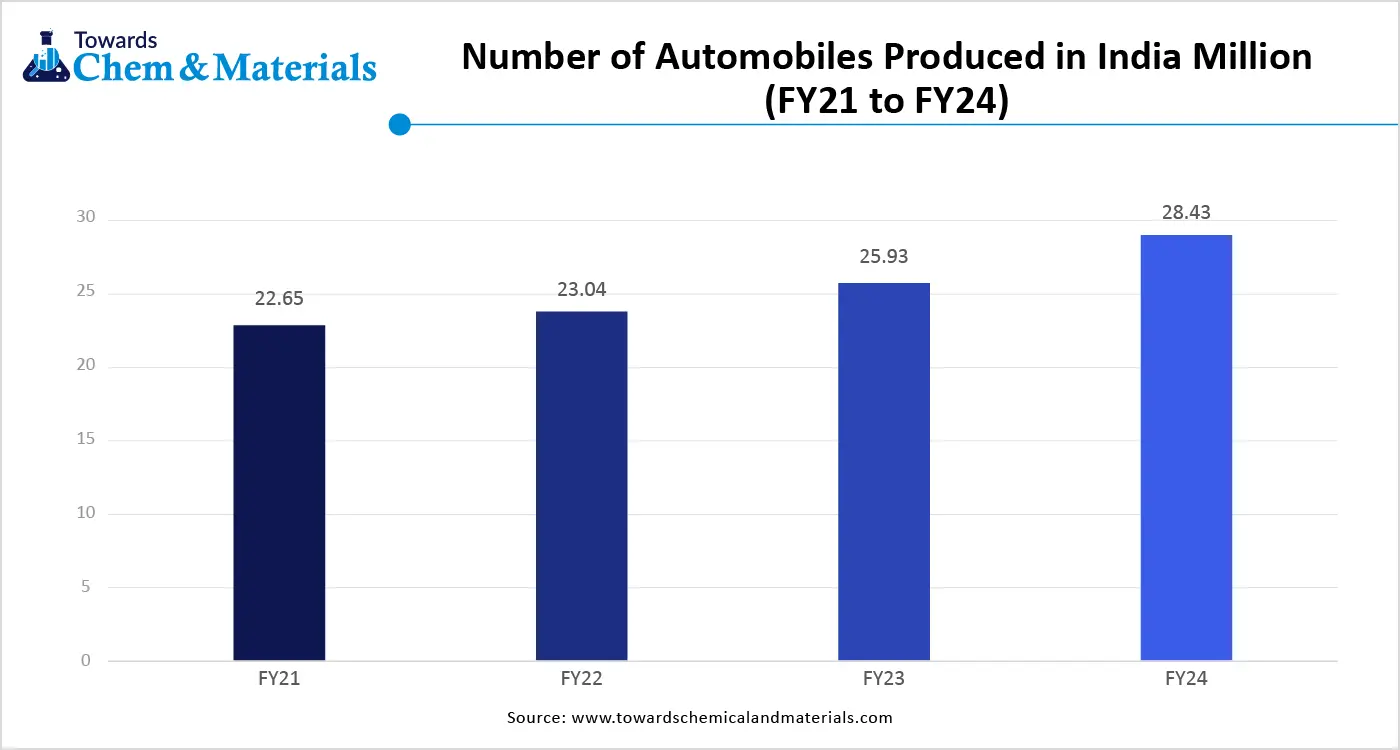

Growing Automotive Industry

The increasing production of automobiles and the growing automotive industry increase demand for plastic, which requires mechanical recycling. The strong focus on minimizing vehicle weight and lowering emissions of vehicles increases the adoption of mechanical recycling to develop lightweight vehicle components.

The growing adoption of electric vehicles and automakers' focus on minimizing environmental footprint increases demand for mechanical recycling. The growing manufacturing of vehicle parts like dashboard panels, armrests, door trims, seat upholstery, bumper fascia, fender cover, and bumpers increases the adoption of mechanical recycling. The growing automotive industry creates an opportunity for the growth of the mechanical recycling of plastics market.

Market Challenge

High Processing Cost Halts Market Growth

Despite several benefits of the mechanical recycling of plastics across various applications, the high processing cost restricts the market growth. Factors like degradation of plastic quality, expensive sorting process, and contamination risk are responsible for the high processing cost. The complex material types and sorting & collecting of various plastics are labor-intensive, which increases the cost.

The extensive need for cleaning and the requirement for specialized equipment result in a high cost. The need for specialized infrastructure for processes like shredding, pelletizing, sorting, & washing increases the cost. The high processing cost hampers the growth of the mechanical recycling of plastics market.

Regional Insights

Asia Pacific Mechanical Recycling of Plastics Market Trends

Asia Pacific dominated the market with approximately 48% share in 2024. The growing consumption of plastic and the rise in manufacturing activities increase demand for mechanical recycling. The stricter waste management regulations in countries like India, South Korea, China, and Japan help the market growth.

The growing expansion of packaging infrastructure and high generation of plastic increase demand for mechanical recycling. The well-established recycling infrastructure and growing awareness about plastic pollution drive the market growth.

China Mechanical Recycling of Plastics Market Trends

China is a major contributor to the market. The high production of plastic and increasing consumption of plastic increase demand for mechanical recycling. The growing industries like automotive, construction, packaging, and electronics increase demand for mechanical recycling for the utilization of recycled materials. The growing investment in recycling technology and the increasing adoption of sustainable packaging support the overall market growth.

- China exported 7,840 shipments of shredders.(Source: www.volza.com)

- China exported 2,281 shipments of plastic extruder machines.(Source: www.volza.com)

North America Mechanical Recycling of Plastics Market Trends

North America is experiencing the fastest growth in the market during the forecast period. The various corporate sustainability initiatives and stricter environmental regulations increase the adoption of mechanical recycling.

The growing consumer awareness about plastic waste and government investment in recycling technology increases the adoption of mechanical recycling. The presence of advanced recycling infrastructure and growing end-user industries like electronics, packaging, & automotive drives the market growth.

United States Mechanical Recycling of Plastics Market Trends

The United States is a key contributor to the mechanical recycling of plastics market. The increasing use of recycled materials and corporate sustainability goals increases the adoption of mechanical recycling.

The stricter regulations in states like New York & California and innovations in sorting technologies increase demand for mechanical recycling. The growth in end-user industries like consumer goods, packaging, and automotive increases the adoption of mechanical recycling, supporting the overall market growth.

- The United States exported 475 shipments of shredders.(Source: www.volza.com)

Segmental Insights

Recycling Process Insights

Why Extrusion Segment Dominates the Mechanical Recycling of Plastics Market?

The extrusion segment dominated the market with approximately 35% share in 2024. The cost-effectiveness in manufacturing and ability to mold into various shapes like profiles, pipes, & sheets increases demand for extrusion. The high volume production of recycled plastic and a strong focus on energy savings increase demand for extrusion. The increasing need for efficient waste transformation and melt blending capabilities requires extrusion, driving the overall market growth.

The pelletizing segment is the fastest-growing in the market during the forecast period. The strong focus on minimizing landfill waste and reducing the consumption of energy increases demand for pelletizing. The stringent waste management regulations and increasing awareness about plastic waste increase the adoption of pelletizing. The growing end-user industries like automotive, textile, packaging, and construction increase the adoption of extrusion, supporting the overall market growth.

Source of Plastic Waste Insights

How the Post-Consumer Recycled (PCR) Segment Held the Largest Share in the Mechanical Recycling of Plastics Market?

The post-consumer recycled (PCR) segment held the largest revenue share of approximately 60% in the market in 2024. The strong focus on conserving resources and growing adoption of sustainable products increases demand for PCR. The stringent regulations on plastic pollution and the growing expansion of packaging application increases demand for PCR. The growing demand for PCR across industries like electronics, automotive, and consumer goods drives the overall market growth.

The post-industrial recycled (PIR) segment is experiencing the fastest growth in the market during the forecast period. The strong focus on lowering landfill waste and minimizing environmental impact increases demand for PIR. The growing adoption of sustainable solutions in businesses and advancements in recycling technology increase demand for PIR. The growing manufacturing of automotive parts and electronic components increases demand for PIR, supporting the overall market growth.

Polymer Type Insights

Why is the Polyethylene Segment Dominating the Mechanical Recycling of Plastics Market?

The polyethylene (PE) segment dominated the market with approximately 32% share in 2024. The inexpensive to manufacture and focus on meeting sustainability goals increases the adoption of polyethylene. The growing manufacturing of bags, bottles, pipes, and films increases demand for PE.

The increasing manufacturing of construction materials and automotive parts increases the adoption of PE. The increasing production of household utensils, agricultural films, and building materials requires PE, driving the market growth.

The polycarbonate (PC) segment is the fastest-growing in the market during the forecast period. The growing demand for sustainable materials and the increasing production of consumer electronics increase demand for polycarbonate. The high-performance properties and focus on lightweight nature increase the adoption of polycarbonate. The advancements in mechanical recycling technology and increasing production of products like construction materials & medical equipment increase demand for polycarbonate, supporting the overall market growth.

Product Form Insights

How Flakes Segment Held the Largest Share in the Mechanical Recycling of Plastics Market?

The flakes segment held the largest revenue share of approximately 76% in the mechanical recycling of plastics market in 2024. The ease of production and cost-effective process increases demand for flakes. The growing production of plastic products like bottles, fibers, and sheets increases demand for flakes. The easy-to-wash and compatibility with existing manufacturing systems increase the adoption of flakes. The growing end-user industries like consumer goods, textiles, and packaging increase the adoption of flakes, supporting the market growth.

The pellets segment is experiencing the fastest growth in the market during the forecast period. The focus on easy-to-handle processes and the need to minimize landfill waste increases demand for pellets. The growing manufacturing of automotive components and production of bags & bottles increases demand for pellets. The growing use of pellets in applications like consumer goods, textiles, and carpets supports the overall market growth.

Application Insights

Which Application Segment Dominated the Mechanical Recycling of Plastics Market?

The packaging segment dominated the mechanical recycling of plastics market with approximately 38% share in 2024. The growth in consumer goods and increasing packaging of food & beverages increases demand for mechanical recycling.

The increasing consumption of packaged food and the growing manufacturing of single-use items increase demand for mechanical recycling. The growing manufacturing of various packaging, such as containers, flexible packaging, bottles, and films, increases demand for mechanical recycling, driving the overall growth of the market.

The automotive components segment is the fastest-growing in the market during the forecast period. The strong focus on the production of lightweight vehicles and the focus on extending battery range increase the adoption of mechanical recycling.

The rise in adoption of electric vehicles and increasing production of components like interior trims, bumpers, and dashboards increases demand for mechanical recycling. The growing manufacturing of under-the-hood components and external automotive components supports the overall market growth.

Recent Developments

- In May 2025, NOVA Chemicals launched the world’s largest mechanical recycling facilities, SYNDIG01 for polyethylene film in Indiana. The facility is present in Connersville across 450000 square feet. The recycling capacity of the facility is 145000 bales, and recycled plastic is useful for non-food-grade & food-grade applications.(Source: www.novachem.com)

- In September 2025, GCR launched industrial-scale PCR polyolefins, CICLINXT. The PCR supports sustainability goals and produces high-quality recycled materials. The CICLINXT supports applications like personal care, consumer goods, household products, flexible & rigid packaging, and building materials.(Source: www.hydrocarbonprocessing.com)

Top Companies List

- ALPLA Group: The Austria-based company, leading plastic recycling and packaging manufacturers that involves key technologies like extrusion blow molding, injection molding, & injection stretch blow molding.

- MBA Polymers: The company works on post-consumer recycled plastic to manufacture home equipment, electronics parts, automobiles, and appliances.

- Veolia Environnement: The French-based company works on waste management, involving processes like collection, treatment, disposal, and recycling of waste.

- SUEZ Recycling & Recovery: The global company that specializes in waste management by recycling plastic to support sustainability.

- Tomra Systems ASA: The Norwegian-based company offers advanced collection and sorting technologies for plastic waste.

Other Top Companies

- EREMA Group

- Polystar Machinery Co., Ltd.

- Vecoplan AG

- Herbold Meckesheim GmbH

- KOWIN Plastic Machinery Co., Ltd.

- Starlinger & Co. GmbH

- B+B Anlagenbau GmbH

- ASG Recycling Machinery

- Pluto Intero

- Archana Extrusion Machinery Mfg.

- Sorema S.p.A.

- Doll Plast S.r.l.

- Plasmac S.r.l.

- Next Generation Recyclingmaschinen GmbH

- Moretto S.p.A.

Segments Covered

By Recycling Process

- Shredding

- Washing

- Extrusion

- Pelletizing

By Source of Plastic Waste

- Post-Consumer Recycled (PCR)

- Post-Industrial Recycled (PIR)

By Polymer Type

- Polyethylene (PE)

- Low-Density (LDPE)

- High-Density (HDPE)

- Linear Low-Density (LLDPE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide (PA)

- Polyoxymethylene (POM)

By Product Form

- Pellets

- Flakes

- Sheets

- Films

- Granules

By Application

- Packaging

- Rigid Packaging

- Flexible Packaging

- Automotive Components

- Construction Materials

- Consumer Goods

- Textiles

- Agriculture

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East & Africa

- South Africa

- UAE

- Saudi Arabia

- Kuwait