Content

India Foam Market Size and Growth 2025 to 2034

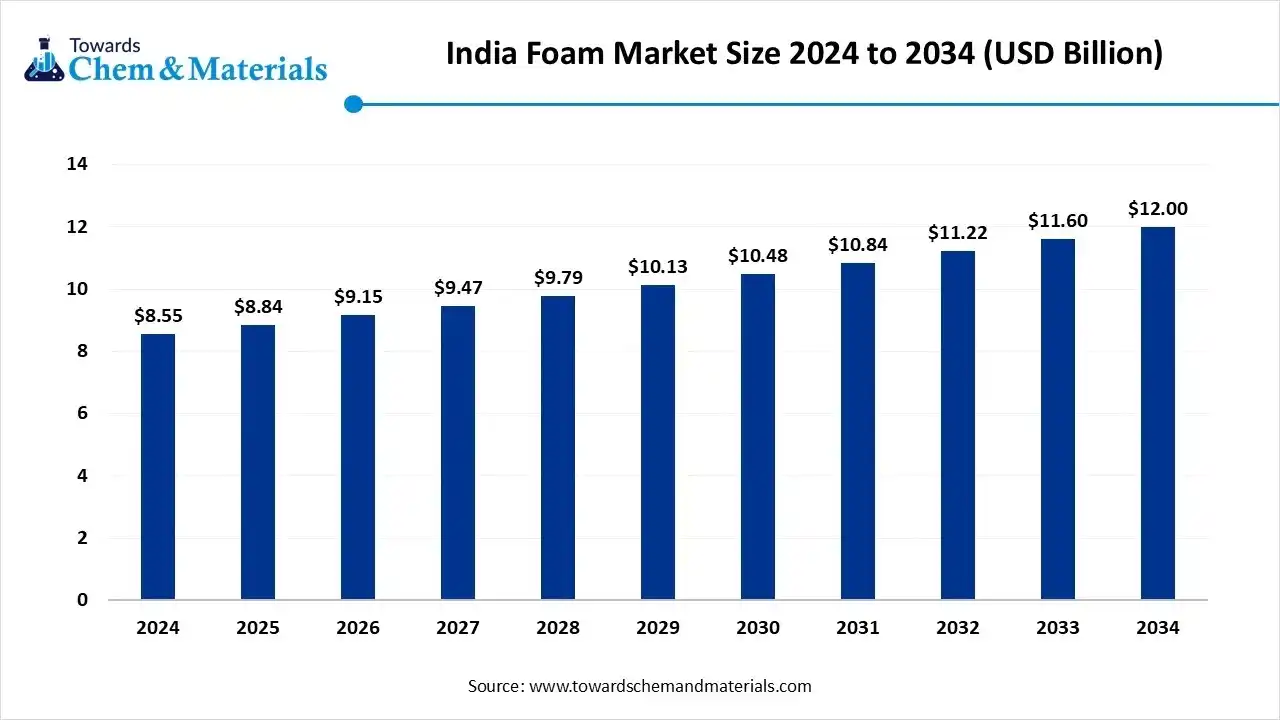

The India foam market size is calculated at USD 8.55 billion in 2024, grew to USD 8.84 billion in 2025, and is projected to reach around USD 12.00 billion by 2034. The market is expanding at a CAGR of 3.45% between 2025 and 2034. Enlarged expansion of e-commerce packaging is expected to attract greater investment in manufacturing in India.

Key Takeaways

- By foam type, the flexible foam segment led the market in 2024.

- By foam type, the spray foam segment is expected to grow at the fastest rate in the market during the forecast period.

- By material, the polyurethane segment emerged as the top-performing segment in the market in 2024.

- By material, the polyolefins segment is expected to lead the market in the coming years.

- By application, the packaging segment led the India foam market in 2024.

- By application, the medical segment is expected to grow at the fastest rate in the market during the forecast period.

- By density, the low density segment led the market in 2024.

- By density, the high density segment is expected to capture the biggest portion of the market in the coming years.

Is India’s Foam Industry the Next Big Growth Story?

The India foam industry has experienced rapid growth in recent years. The factors such as the packaging expansion, rapid urbanisation, and need for modern healthcare infrastructure are facilitating new opportunities for the industry in the current period. Moreover, the Indian foam manufacturers are seen as investing in biobased foam initiatives, which is likely to aid in business diversification for producers in the coming years.

Revolutionizing Shipping with Smart Foam Solutions

The enlarged expansion of e-commerce packaging is mobilizing growth across the regional foam sector in recent years. Furthermore, the business owners in India are seeking damage-free product deliveries while using the foam material for the packaging. Also, by offering lightweight cushioning, the foam is being hailed as a disruptive force in the sector. Additionally, foam material is seen as providing lower shipping cost advantages.

Market Trends

- The adoption of a modern lifestyle has improved financial performance and sector potential in recent years. as the country has observed in pushing initiatives like energy-efficient infrastructure development.

- The increased need for the foam in the Indian medical and healthcare sector is actively reshaping the market dynamics and increasing opportunity windows in the present period.

Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 8.84 Billion |

| Expected Size by 2034 | USD 12.00 Billion |

| Growth Rate from 2025 to 2034 | CAGR 3.45% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Segment Covered | By Foam Type, By Material, By Application, By Density |

| Key Companies Profiled | Sheela Foam Limited, Carpenter Engineered Foams, U-FOAM , Flexipol Foams Pvt. Ltd., Shree Malani Foams |

Market Opportunity

Sustainable Foam Solution Set to Transform Key Industries

The development of recycled and cost-effective foams is expected to attract increased capital and investment in Indian manufacturing in the coming years. Also, the manufacturer can develop foams specifically for major sectors like medical and packaging, where these businesses are under heavy pressure for the replacement of non-degradable plastic products.

Market Challenge

Petrochemical Dependence Puts Foam Manufacturing at Risk

The raw material price volatility is likely to prevent firms from capitalizing on emerging opportunities in the coming years. Furthermore, the major traditional foam production is dependent on the petrochemical supplies and price, which have seen unstable in recent years. Also, the global trade wars and increasing geopolitical tensions are projected to challenge inventory management and logistics

Segmental Insights

Foam Type Insights

How Did The Flexible Foam Segment Dominate The India Foam Market In 2024?

The flexible foam segment held largest share of the market in 2024, due to its wide usage across major sectors in India, such as furniture, automotive seating, and mattresses, in recent years. Moreover, rapid urbanization has heavily contributed to the industry's growth in recent years, where flexible foam is considered a crucial element in the current period.

The spray foam segment is expected to grow at a notable rate during the predicted timeframe, owing to the country’s sudden shift towards energy efficiency and construction activity. Moreover, the Indian government is actively seen in pushing sustainable development practices and motives for energy-efficient building development, where the spray foam is likely to play a major role in the upcoming years in India.

Material Insights

Why Does The Polyurethane Segment Dominate The India Foam Market?

The polyurethane segment held a Greater Industry share of the India foam market in 2024 due to its multi-application advantage -from bedding and furniture to automotive seating and footwear. Indian consumers increasingly prefer lightweight, durable, and cost-efficient materials, all of which PU foams deliver. Their adaptability in rigid and flexible forms makes them ideal for both comfort and industrial uses.

The polyolefins segment is expected to grow at a notable rate during the forecast period, because of India's rising packaging, medical, and automotive needs, coupled with increasing sustainability awareness. Unlike PU foams, polyolefin foams are more recyclable and lightweight, aligning with India's shift toward eco-friendly solutions.

Applications Insights

How did the Packaging Segment Dominate the India Foam Market in 2024?

The packaging segment dominated the market with a major share in 2024, the rise of e-commerce, electronics, and consumer goods sectors. Foam packaging ensures product safety during transport, which is crucial for India's expanding logistics and delivery industry. Electronics, glassware, and fragile products rely heavily on protective foam.

The medical segment is expected to grow at a significant rate during the predicted period, because of the rapid growth of healthcare infrastructure and exports of medical devices. Foams are used in wound dressings, orthopedic supports, surgical pads, and hospital bedding, offering both comfort and hygiene. India's government initiatives like "Make in India" for medical devices will increase local production, raising foam consumption in healthcare

Density Insights

What Makes Low Density Foam the Preferred Choice for Mass Products?

The low density segment dominated the market with the largest share in 2024 because of its cost-effectiveness and bulk demand across mattresses, furniture, and packaging. In price-sensitive markets like India, affordability is a key driver, and low-density foams are cheaper to produce and widely available. Their lightweight property makes them suitable for packaging and comfort products, which are mass consumed.

The high-density segment is expected to grow at a significant rate during the forecast period, because of India's rising demand for durability, performance, and specialized applications. Consumers are gradually moving from low-cost to premium, longer-lasting mattresses and furniture. In the automotive sector, high-density foams are essential for vibration control, seat cushioning, and safety features.

India Foam Market Value Chain Analysis

- Distribution to Industrial Users: The foams in India are manufactured and distributed to the major sectors like chemical, automotive, and construction.

- Chemical Synthesis and Processing: The chemical synthesis and processing of foam in India is mainly considered for polyurethane foam, which includes chemical processes like polymerization, and others

- Regulatory Compliance and Safety Monitoring: The safety monitoring and regulatory compliance of foam in India has worked under the indian standard or IS Codes and guidelines like NFPA.

Recent Developments

- In September 2024, the VFI group established a new foam production plant in India. Also, the plant has advanced machinery and has the capacity to produce 4000 mattresses a day filled with polyurethane foam.(Source: www.utech-polyurethane.com)

India Foam Market Top Companies

- Sheela Foam Limited

- Carpenter Engineered Foams

- U-FOAM

- Flexipol Foams Pvt. Ltd.

- Shree Malani Foams

Segment Covered

By Foam Type

- Flexible Foam

- Polyurethane Foam

- Polyethylene Foam

- Polypropylene Foam

- Latex Foam

- Memory Foam

- Rigid Foam

- Polyurethane Foam (rigid type)

- Polystyrene Foam

- Phenolic Foam

- Molded Foam

- Expanded Polystyrene (EPS)

- Expanded Polypropylene (EPP)

- Expanded Polyethylene (EPE)

- Spray Foam

- Open Cell Spray Foam

- Closed Cell Spray Foam

- Specialty Foam

- Melamine Foam

- Silicone Foam

By Material

- Polyurethane

- Polystyrene

- Polyolefins

- Silicone

- Phenolic

- Melamine

By Application

- Packaging

- Food & Beverage Packaging

- Industrial Protective Packaging

- Consumer Electronics Packaging

- Medical Packaging

- Building & Construction

- Thermal Insulation

- Soundproofing

- Roof & Wall Insulation

- Automotive

- Interior Components

- Exterior Components

- Acoustic & Thermal Insulation

- Furniture & Bedding

- Mattresses

- Cushions & Pillows

- Upholstery

- Footwear

- Insoles

- Footwear Padding

- Medical

- Medical Cushions

- Surgical Pads

- Industrial

- Gaskets & Seals

- Vibration Dampening

By Density

- Low Density

- Medium Density

- High Density