Content

What is the Current Ceramic Membrane Market Size and Share?

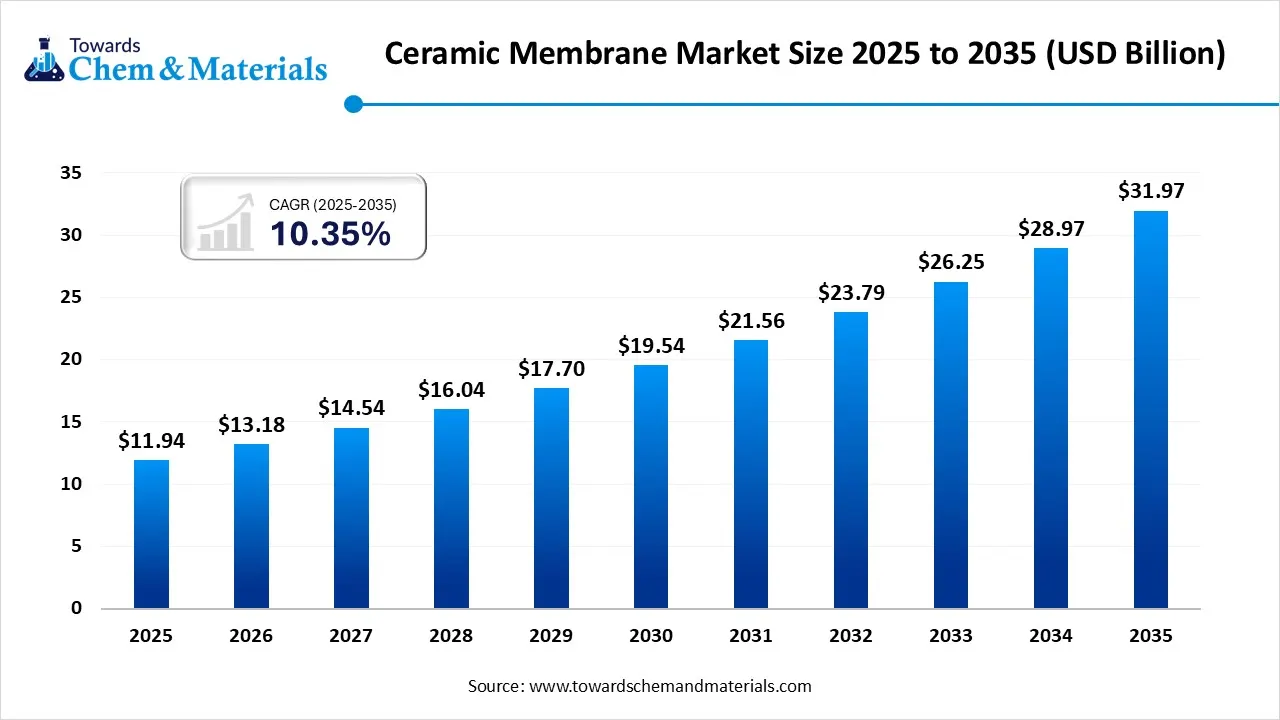

The global ceramic membrane market size was USD 11.94 billion in 2025 and is predicted to increase from USD 13.18 billion in 2026 and is expected to be worth around USD 31.97 billion by 2035, growing at a CAGR of 10.35% from 2026 to 2035. North America dominated the ceramic membrane market with the largest revenue share of 22.02% in 2025.The growing demand for clean water and high-purity filtration from various industries like pharmaceuticals, food and beverage, biotechnology, chemical processing, and water & wastewater treatment drives the growth of the market.

Ceramic Membrane Market Key Takeaways

- The U.S ceramic membrane market size was estimated at USD 1.98 billion in 2025 and is projected to grow at a CAGR of 10.87% from 2025 to 2035.

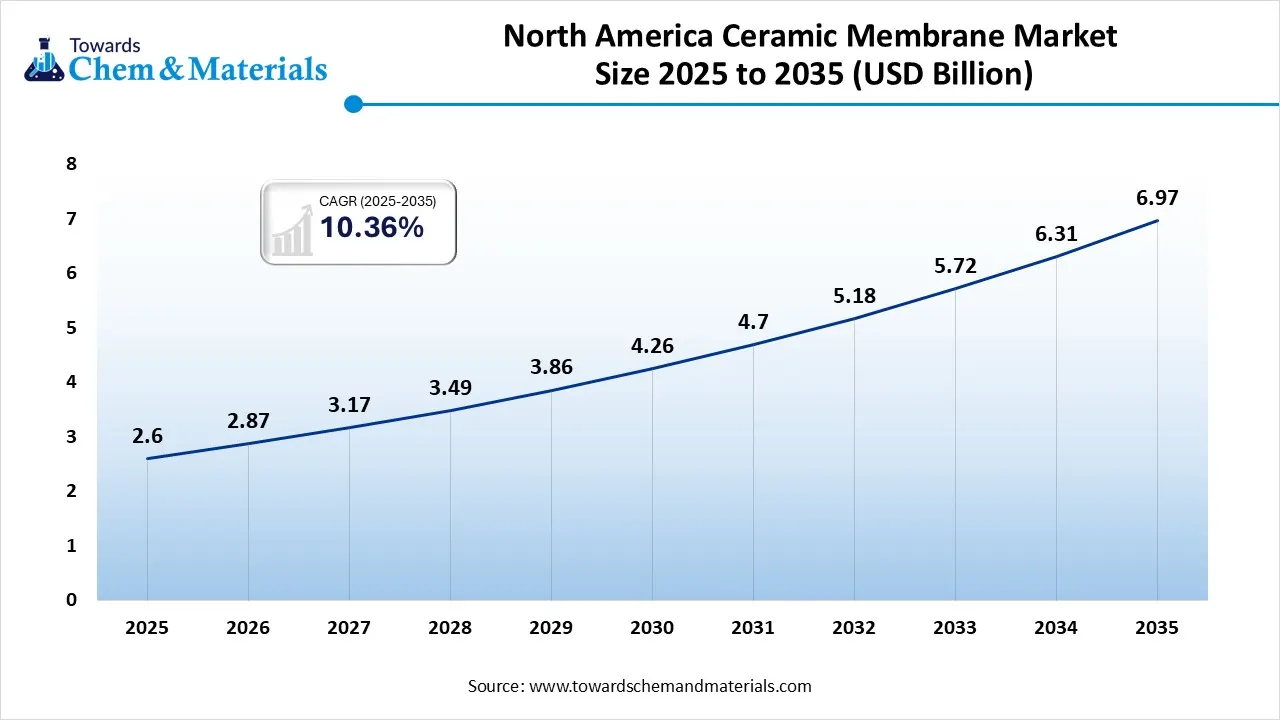

- North America dominated the ceramic membrane market with the largest revenue share of 22.02% in 2025.

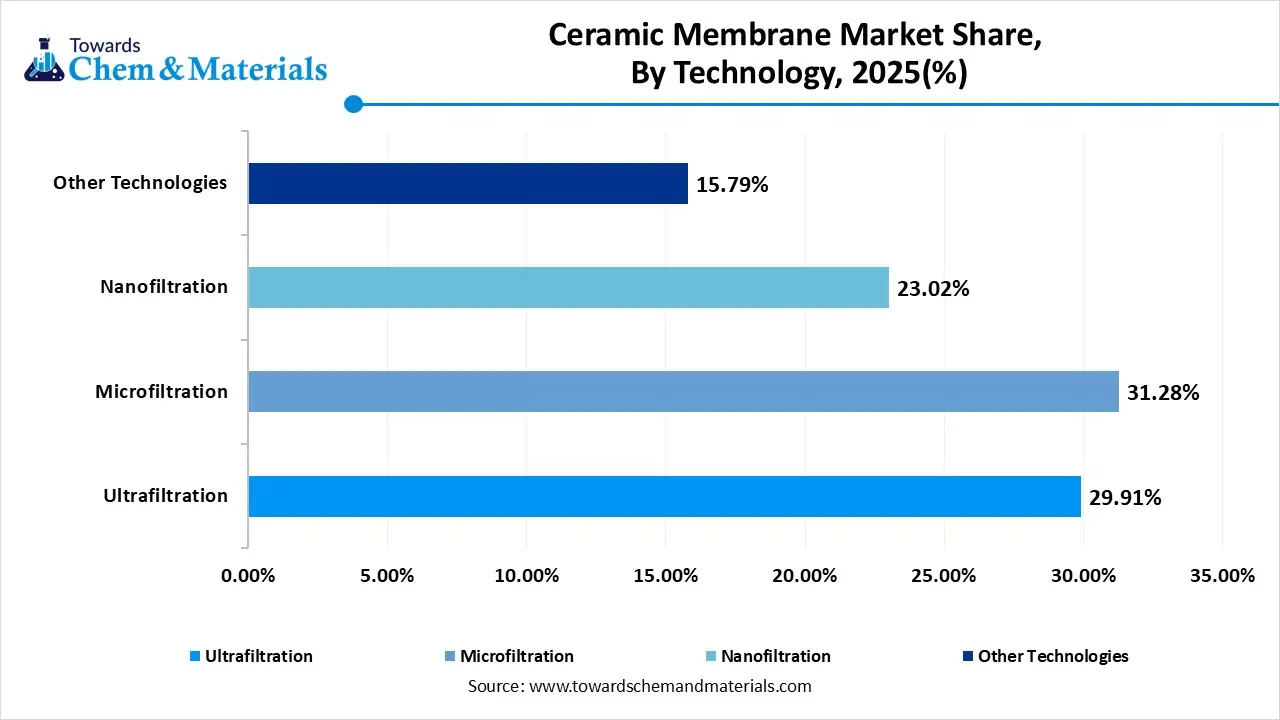

- By technology, the microfiltration technology dominated the market with a revenue share of 32.33% in 2025.

- By application, the water & wastewater treatments segment led the market with the largest revenue share of 48.09% in 2025

- By application, the Pharmaceutical application is anticipated to grow at a significant growth rate of 12.35% over the forecast period.

Ceramic Membrane Market Overview

A ceramic membrane is made up of inorganic materials, and it is a type of artificial membrane. It is formed using a combination of metals like aluminum, titanium, silicium, & zirconium and non-metals like oxide, nitride, or carbide, which are in the form of oxide. It has thermal stability, high chemical resistance, and durability. Ceramic membranes have a sandwich-like structure & consist of three layers, including an active layer, a support layer, and an intermediate layer.

An active layer is used for separation, a macroporous layer provides mechanical strength to the process, and an intermediate layer enhances permeability and surface uniformity. The active layer or dense layer has a thickness of 5- 10 micrometers & porosity range of 30-50%; the intermediate layer has a thickness of 30- 45 micrometers, and its porosity is approximately 40%, and the microporous layer has a thickness of 1.5-2micrometer & porosity is 40-45%. To synthesize ceramic membranes, the sol-gel method and surface modification method are used.

Ceramic membranes are used in various applications like liquid filtration, gas separation, and wastewater treatment. The rising demand for high-purity filtration and stringent environmental rules and regulations are responsible for the growth of the market. The growing water shortage problems in various regions and the rising demand for advanced filtration from various industries drive the growth of the ceramic membrane market.

Growing Demand from The Food & Beverage Sector

The food & beverage industry is a growing industry, and it uses ceramic membranes due to their high separation efficiency, chemical stability, and ability to sustain in harsh environmental conditions. Ceramic membrane used in sweetener concentration & purification, produces concentrated milk proteins & isolated milk proteins. Technology is widely applied to eliminate bacteria from milk and the processing of flavouring & seasoning. The rising application from the dairy industry to separate fat, extract whey protein, remove microbial, and filter skimmed milk helps in market growth.

In the beverage industry, the production of alcoholic drinks like beer & wine and the process of juice clarification to remove bacteria, pectin, crude protein, and suspended solids to avoid juice spoilage, ceramic membrane is used. This membrane is also used in vinegar sterilization & clarification and in soy sauce production to separate sediment, turbidity, and bacteria. Rising restaurants, bars, cafes, catering services, fast food outlets, and food courts increase the demand for ceramic membrane due to this market is growing.

Ceramic Membrane Market Trends

- Rising water shortage problem: Water scarcity problem rises in many regions to solve this problem ceramic membrane is used. It enables an efficient water purification method and uses desalination and wastewater treatment processes for the reuse of water.

- Eco-friendliness and sustainability of ceramic membrane: Ceramic membrane can be reused multiple times, and it needs frequent replacement due to this waste material is reduces.

- Growing application in biomedicine industry: Ceramic membrane helps in separating and purifying therapeutic proteins, enzymes, and monoclonal antibodies in biomedicine process.

- Rising wastewater from industry: The growing wastewater from various industries increases the demand for wastewater treatment. The ceramic membrane removes impurities and contaminants by using cross-flow filtration techniques.

- Long lifespan: The ceramic membrane lowers the clogging process and has a long lifespan. A long lifespan helps to reduce the overall optional cost of the process.

Ceramic Membrane Market Report Scope

| Report Attributes | Details |

| Market Size in 2026 | USD 13.18 Billion |

| Expected Size in 2035 | USD 31.97 Billion |

| Gowth Rate | CAGR of 10.35% |

| Base Year Of Estimation | 2025 |

| Forecast Period | 2026-2035 |

| High Impact Region | North America |

| Segment Covered | By Technology,Application,region |

| Key Companies Profile | GEA Group Aktiengesellschaft; Pall Corporation; Hyflux Ltd; Kovalus Separation Solutions; Nanostone; Veolia; TAMI Industries; METAWATER Co., Ltd.; ITN Nanovation AG; SIVA Unit |

Ceramic Membrane Market Opportunity

Rising Demand from The Chemical Industry

In the chemical industry, ceramic membranes are used in various applications. Ceramic membrane usage in the chemical industry is a game-changer due to its wide applications. This membrane is widely used in wastewater treatment, catalyst recovery, oil-water separation, and purification of liquid in the chemical industry. In the process of the purification of liquids like phosphoric acid and recovering catalysts from chemical processes, it needs a ceramic membrane. Chemical processes include solvents and harsh environments like high temperature, and wastewater generated from chemical process is acidic and alkaline to treat this water requires advanced wastewater treatment technology like ceramic membrane.

This membrane is sustained in harsh environment conditions due to its solvent resistant and high-temperature resistant property. Properties like high mechanical strength, high chemical stability, resistance to microbial attack, durability, high flux, and easy-to-regenerate material make it suitable for the chemical process. The growing demand from the chemical industry increases the demand for the usage of ceramic membranes.

Technological Development Transforms Ceramic Membrane Market

Various industries such as food and beverages, chemical, pharmaceutical, and textile utilize ceramic membrane technology for various applications. The rising application of ceramic membranes demands advancement in technology. Development such as improve materials, fabrication methods and surface modification to boost performance, durability, and filtration process of ceramic membrane.

Researchers are searching for new low-cost ceramic material to reduce overall cost and to enhance thermal and mechanical strength. Researchers are addressing limitations like high cost and complex manufacturing processes. Advanced technological development in the ceramic industry will fuel the growth of the market in the future.

Ceramic Membrane Market Challenge

High Cost of Raw Materials and Manufacturing

Despite several benefits of ceramic membrane, high raw material and manufacturing cost restricts the growth of the market. Raw materials like alumina, zirconia, and titania are expensive. The fabrication method for ceramic membranes requires a high-temperature sintering and forming stage, and the process needs significant energy, increasing the cost of the overall process. Generating accurate pore sizes is a complex process, and smaller pore sizes are more expensive.

Factors like larger surface area require more ceramic material, which influences the cost. The rising cost of the machining process and post-processing, including grinding, lapping, or polishing, hampers market growth. The expensive raw materials and manufacturing process hampers the growth of the market.

Value Chain Analysis

Research & Development (R&D)

- This involves optimizing material synthesis to enhance permeability, fouling resistance, and selectivity.

- Key Players: Saint-Gobain, Morgan Advanced Materials, CoorsTek, Kyocera Corporation, and Central Glass and Ceramic Research Institute.

Fabrication and Manufacturing

- This involves a highly energy-intensive process involving shaping/extrusion of the raw materials into tubular or flat-sheet supports, coating of the active layer, and sintering in high-temperature furnaces.

- Key Players: TAMI Industries, Pall Corporation, LiqTech International, GEA Group, Metawater Co., Ltd., Nanostone Water, and Atech Innovations.

Membrane Module and System Assembly

- This involves integrating the fabricated membrane elements into modules and subsequently into full filtration skids, including pumps, control systems, and sensor technology for real-time monitoring.

- Key Players: Veolia Water Technologies, Aquatech International, Qua Group LLC, H2O Innovation, and Toray Industries.

Logistics and Distribution

- This involves transporting robust but heavy ceramic components for global water treatment or industrial projects.

- Key Players: Pall and Veolia.

Treatment, Installation, and Commercialization

- This involves installation of systems in end-user applications, including water/wastewater treatment, food & beverage, chemical processing, and pharmaceutical sterile filtration.

- Key Players: Pall Corporation,

Ceramic Membrane Market Segmental Insights

By Technology Insights

The microfiltration segment dominated the ceramic membrane market in 2025. The commercial availability, process reliability, and feasibility drive the growth of the market. This process removes large suspended solids, bacteria, and other contaminants from water. Microfiltration membranes contain pores, and their size ranges from 0.1 to 10 microns. Pressure forces the liquid through pores, and it helps to retain larger particles. Furthermore, the wide applications in various industries, such as water and wastewater treatment, Food & beverages, pharmaceuticals, and biotechnology due to its feasibility drives the growth of the market in the region.

The ultrafiltration segment expects the fastest growth in the ceramic membrane market during the forecast period. The rising demand for durable and high-performance solutions drives the growth of the market. The growing water reuse projects and stringent environmental rules & regulation increases the demand for the ultrafiltration segment. Ultrafiltration is a type of membrane filtration that forces water and small particles through a semipermeable membrane, and its pore size ranges from 0.001 to 0.1 microns. It retains larger particles, colloids, and high-molecular-weight substances.

The growing demand for separation of high-molecular weight compound from aqueous and non-aqueous solution demands ultrafiltration technology. Additionally, rising use in industries like textile, chemical processing, paper manufacturing, pharmaceutical, biotechnology, food & beverage, and water treatment drives the growth of the market.

By Application Insights

The water and wastewater segment dominates the ceramic membrane market in 2025. The longer service life, strong mechanical strength, and superior filtration ability drive the growth of the market. The rising civilization and industrialization increased the demand for effective wastewater treatment, which helped in the growth of the market.

Ceramic membranes help to remove particles, bacteria, and viruses from water. The growing demand for drinking water treatment and industrial waste water treatment drives the growth of the market. The rising water crisis due to industrialization and the need for sustainable water choices demands advanced water purification ceramic membrane technologies. Furthermore, the stringent government rules and regulations to protect the environment from hazards drive the growth of the market.

The pharmaceutical segment is expected to grow at the fastest rate in the market during the forecast period. The rising need for high-purity filtration and purification in the production of drugs drives the growth of the market. The growing demand from various applications, including bioprocess filtration, virus filtration, microorganism elimination, and separation & purification of proteins and enzymes, fuels the growth of the market. Furthermore, the manufacturing process of biologics and vaccines uses ceramic membranes to remove viruses and other contaminants.

Ceramic Membrane Market Regional Insights

North America shaping the ceramic membrane market

The North America ceramic membrane market size was valued at USD 2.60 billion in 2025 and is expected to be worth around USD 6.97 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 10.36% over the forecast period from 2026 to 2035. North America dominated the ceramic membrane market with the largest share in 2025. The well-established manufacturing base and stringent environmental regulations in the region drive the growth of the market. The region has a strong infrastructure for water and wastewater treatment, and robust investment in technologies fuels the market growth. Furthermore, the strong presence of industrial sectors like pharmaceuticals, chemicals, and food and beverages produces a high amount of wastewater demands, and advanced filtration methods propel the market growth in the region. The rising expansion of oil & gas sectors and the presence of key companies in the region further drive the growth of the market.

United States is growing at the fastest rate over the forecast period in the ceramic membrane market. The stringent environmental regulations initiative by the government and strong investment in the treatment facilities sector drive the growth of the market. The growing research and technological development and rising demand for clean water help in the market growth. Furthermore, the presence of key players in the region and the industrial requirement for advanced filtration techniques drive the market growth.

Ceramic membrane boom in Asia Pacific

Asia Pacific expects significant growth in the ceramic membrane market during the forecast period. The growing industrialization and rapid civilization in the region increase water pollution and demand advanced water treatment methods, driving the market growth. The rising concerns of water scarcity encourage the government to invest in advanced technologies. Countries like China, India, Japan, and South Korea drive the market growth in the region. Furthermore, growing demand from various industries like pharmaceuticals, food & beverage, and biotechnology propels the market growth.

China dominates the ceramic membrane market in the Asia Pacific region.

The rising population demands clean water, and advanced wastewater treatment helps in market growth. The growing civilization, industrialization, and Chinese government support to promote sustainability and protection of the environment support the growth of the market in the region. China’s strong investment in municipal wastewater systems, which includes sludge mitigation, initial rainfall treatment, rainwater-sewage diversion systems, and many more, drives the market growth in the region.

Rising growth of ceramic membrane in Europe

Europe is experiencing significant growth in the ceramic membrane market. The growing focus on sustainability and eco-friendly solutions and advanced industrial infrastructure in the region support market growth. The growing technological innovations and presence of key manufacturers in the region drive the growth of the market.

Germany Flat Glass Coatings Market Trends

Germany plays a distinctive role in the region, primarily due to strict environmental regulations regarding nutrient leaching and EU-wide mandates for biodegradable coatings. The German market is characterized by strong demand for specialty grades, with the horticultural segment expanding rapidly. Companies like BASF and COMPO EXPERT are making significant investments in research and development for polymer-coated granules and biodegradable coating technologies.

Emergence of Latin America in the Flat Glass Coatings Market?

Latin America is emerging as a rapidly growing region in the global market, driven by factors such as industrialization, acute water scarcity, and increasingly stringent environmental regulations related to wastewater treatment. The mining sector, particularly in Chile and Peru, requires durable, high-temperature-resistant ceramic membranes to handle metal-laden, corrosive wastewater, thereby improving product quality. Increased investment in infrastructure and the modernization of municipal treatment networks are promoting the adoption of advanced, automated membrane systems.

Brazil Flat Glass Coatings Market Trends

Brazil stands out as a mature player in the region due to its massive consumption of agricultural inputs. The market for controlled-release fertilizers is expanding quickly, driven by intense demand to maximize yields for crops like soy, corn, and sugarcane. Brazilian farmers are adopting CRFs to improve nutrient use efficiency and comply with environmental regulations. To reduce heavy reliance on imported fertilizers, Brazil is investing in domestic production, with companies like Haifa Group establishing local blending facilities.

How will the Middle East and Africa contribute to the Flat Glass Coatings Market?

The Middle East and Africa are key contributors to the global market, largely due to severe water scarcity, high demand for desalination, and expanding industrial sectors requiring robust filtration solutions. Rapid urbanization and government investment in water infrastructure, particularly in Saudi Arabia, the UAE, and Egypt, are fostering the adoption of advanced membrane technologies. Stringent environmental regulations aimed at reducing industrial discharge are encouraging industries to invest in high-efficiency, sustainable wastewater treatment solutions.

The UAE Flat Glass Coatings Market Trends

The UAE is emerging as a significant player in the region by utilizing CRFs to address arid conditions, focusing on water conservation and reducing nutrient runoff in desert farming. The government promotes high-efficiency fertilizers through subsidies, while major companies like ADNOC are integrating clean technology into fertilizer production. The market is driven by the expansion of protected cultivation and urban landscaping, where there is a strong demand for premium, long-lasting fertilizers.

Ceramic Membrane Market Recent Developments

- In January 2025, NIT Rourkela announced a latest eco-friendly treatment for removing carcinogenic dyes from wastewater. Research states that combining nanocomposite-based ceramic membranes and microbubble technology can enhance the dye removal process. This technology can be used in various industries like textile manufacturing and chemical where robust wastewater treatment is needed.

- In February 2025, Cerafiltec offered ceramic membrane technology for an xAI supercomputer data center in Tennessee. The project is building the largest ceramic membrane bioreactor to enable the reuse of 49.2MLD of municipal water to cool their supercomputer data center. The project helps to eliminate plastic waste from conventional polymeric membranes and minimizes negative environmental impact.

- In November 2024, Scottish Water invited contractor for bidding on the contract valued between £500 million and £800 million, for the advancement of membrane capital investment project.

Ceramic Membrane Market Top Companies List

- Hyflux Ltd.

- Pall Corporation

- Kovalus Separation Solutions

- Veolia

- Nanostone

- Tami Industries

- METAWATER CO., Ltd.

- ITN Nanovation AG

- SIVA Unit

- Jiangsu Jiuwu Hi-Tech Co. Ltd

- LiqTech Holdings A/S

- Atech Innovation GmbH

- H2O Innovation Inc.

- Nijhuis Saur Industries

- Saint-Gobain S.A.

- Aquabrane Water

- ITN Nanovation AG

- SIVA

- Kovalus Separation Solutions

- CTI Oxidation

Segments Covered In The Report

By Technology

- Microfiltration

- Ultrafiltration

- Nanofiltration

- Others

By Application

- Water and wastewater treatment

- Pharmaceuticals

- Chemical Processing

- Food & Beverage

- Biotechnology

- Others

By Regional

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa