Content

Plastics Extruded Market Size & Share Report, 2034

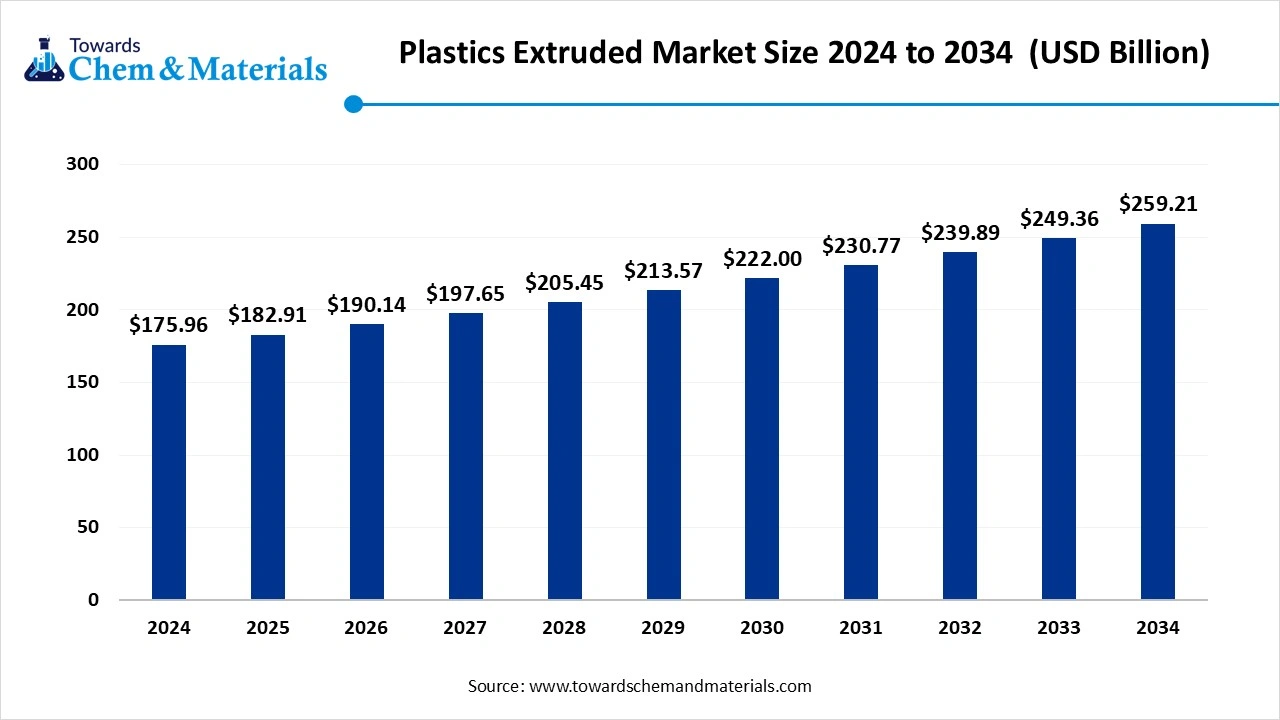

The global plastics extruded market size was reached at USD 175.96 billion in 2024 and is expected to be worth around USD 259.21 billion by 2034, growing at a compound annual growth rate (CAGR) of 3.95% over the forecast period 2025 to 2034. The enlarged expansion of the heavy manufacturing industries has accelerated industry potential in recent years.

Key Takeaways

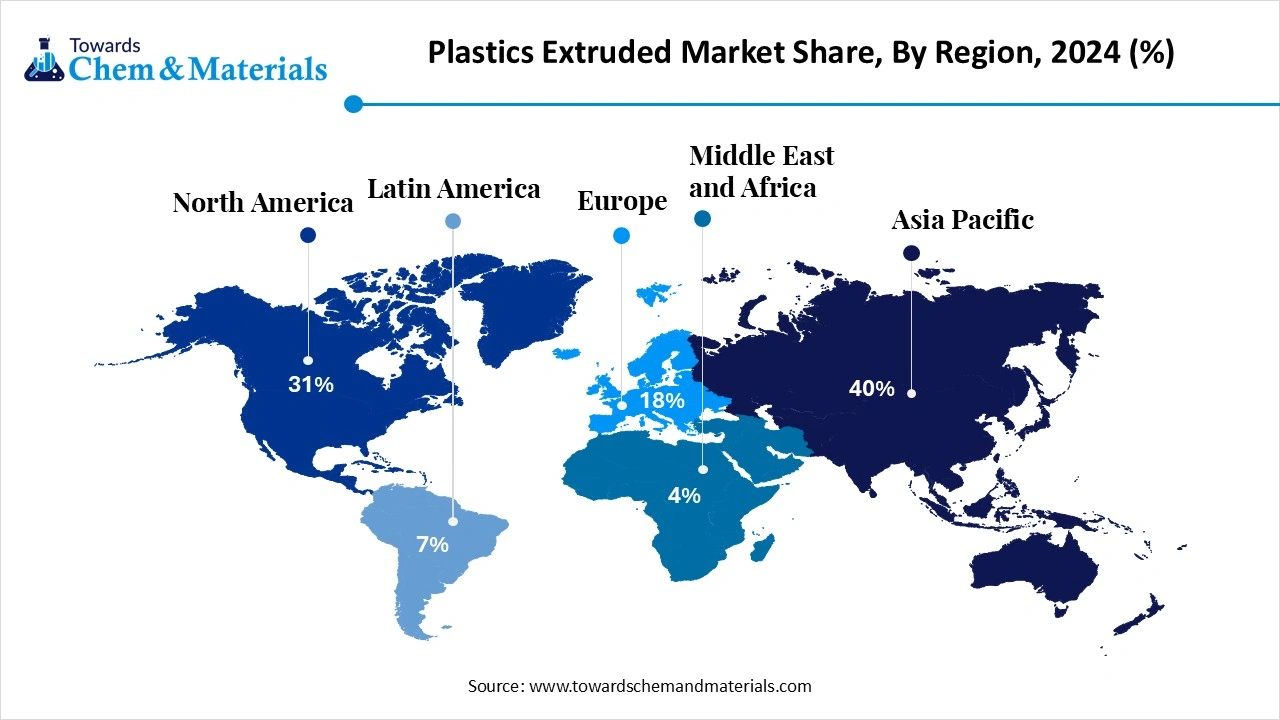

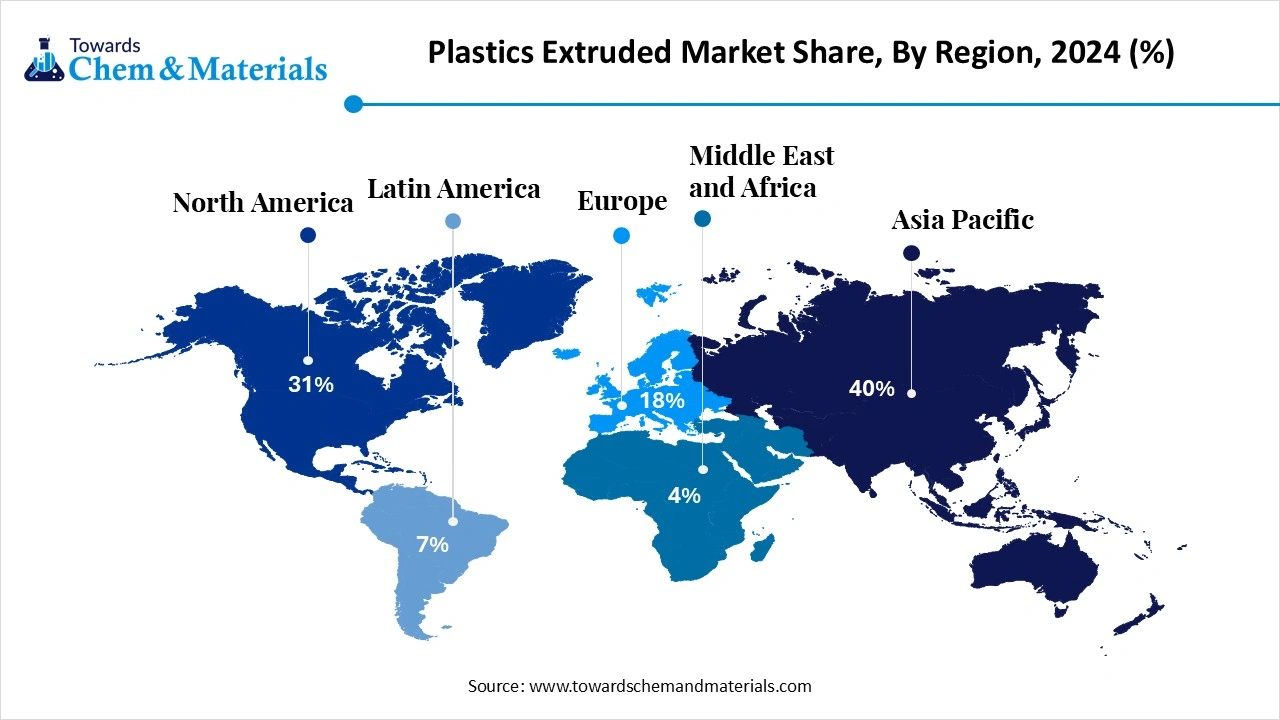

- By region, Asia Pacific dominated the plastics extruded market in 2024 with 40% of the industry share, akin to the enlarged expansion of sectors such as packaging, automotive, and construction.

- By region, North America is expected to grow at a notable rate in the future, owing to the increased need for high-quality plastic in the region nowadays.

- By material type, the polyethylene extrusion segment led the market in 2024 with 35% market share, owing to the increased need for high-quality plastic in the region nowadays.

- By material type, the polypropylene extrusion segment is expected to grow at the fastest rate in the market during the forecast period, akin to the increased need for lightweight material, and the material, which has greater resistance to fatigue and chemicals.

- By process type, the single screw extrusion segment emerged as the top-performing segment in the market in 2024 with 40% industry share, due to it being considered the traditional process and its unique properties, such as the cost effectiveness and simplicity, in recent years.

- By process type, the twin screw extrusion is expected to lead the market in the coming years, due to its better mixability, flexibility, and higher output as compared to the single screw systems.

- By product type, the pipes and tubes segment led the market in 2024 with 30% market share, due to the sudden updation of the regional infrastructure globally.

- By product type, the films and sheet segment is expected to capture the biggest portion of the market in the coming years, due to rising demand in food packaging, agricultural films, medical sheets, and electronics.

- By end-use industry, the packaging segment led the market in 2024 with 25% industry share, due to its widespread use in consumer goods, food & beverages, and industrial applications.

- By end-use industry, the automotive segment is expected to grow at the fastest rate in the market during the forecast period, due to the rising use of lightweight plastics to improve fuel efficiency and reduce emissions.

- By equipment type, the extruders segment led the market in 2024 with 50% industry share, as they form the core of the plastic extrusion process.

- By equipment type, the die heads segment is expected to capture the biggest portion of the market in the coming years, due to the growing demand for precision and customization in extruded products.

- By application type, the packaging films segment led the plastic extrusion market in 2024 with 35% industry share, due to their extensive use in food, personal care, pharmaceuticals, and industrial packaging.

- By application type, the construction profile segment is expected to grow at the fastest rate in the market during the forecast period, due to the booming global Infrastructure and housing sectors.

Market Overview

Inside the Plastics Extruded Market : Process, Products, and Potential

The plastics extruded market is a method of shaping plastic materials by forcing them into a mold or die to create various products with continuous cross-sectional profiles. This process is heavily used in the production of plastic products such as sheets, profiles, films, pipes, and other custom shapes. The market encompasses various technologies, equipment, materials, and end-use industries where extrusion processes are employed.

Which Factor is Driving the Plastics Extruded Market?

The sudden increased need for lightweight and cost-effective plastic products has spearheaded industry growth in recent years. Several major sectors, such as the packaging and automotive sectors, have been actively observed in the replacement of their heavy metal ties with these lightweight plastic products in the past few years. Moreover, by offering high production speed and materials efficiency to heavy manufacturers, plastic products have gained major market share in the current period, as per the industry survey.

Market Trends

- The need for biodegradable and recyclable plastic is driving industry growth nowadays. As several manufacturers are actively implementing sustainable manufacturing initiatives in their plants.

- The sudden growth in the construction and infrastructure projects is contributing to the growth of the industry in the current period. As the demand for plastic profiles, such the pipes, window frames, and cable ducts, has been observed to increase.

Report Scope

| Report Attribute | Details |

| Market Size in 2025 | USD 182.91 Billion |

| Expected Size by 2034 | USD 259.21 Billion |

| Growth Rate from 2025 to 2034 | CAGR 3.95% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Material Type, By Process Type, By Product Type, By End-Use Industry,By Equipment Type, By Application,By Region |

| Key Companies Profiled | BASF SE, SABIC , DSM Engineering Plastics , Dupont , Saint-Gobain , Makrolon® , Michelman, Inc. , Leistritz Extrusionstechnik GmbH , Nordson Corporation, Prism Plastics Inc. , Jain Irrigation Systems Ltd. , PolyOne Corporation , Aluplast GmbH , U.S. Plastic Corp. , Zeus Industrial Products , WITTMANN BATTENFELD , Graham Engineering Corporation , Coperion GmbH , The Dow Chemical Company , Reifenhäuser GmbH |

Market Opportunity

Tailored Extrusion Solutions Poised to Transform Industry Margins

The manufacturers can gain some immense advantages by offering customized plastic extrusion in the upcoming years. Also, entering niche applications like aerospace, medical, and renewable energy is expected to create lucrative opportunities for the manufacturers during the forecast period. Moreover, the manufacturers can create a strategic collaboration with these sectors to produce, where they can gain long-term and sophisticated profit margins with the global consumer base in the upcoming years.

Market Challenge

Volatile Petroleum Prices Disrupt Plastic Manufacturing Flow

The volatility of the raw material price is expected to hamper industry growth in the upcoming years, as raw materials, such as polyethylene and polypropylene, which are primarily derived from petroleum which are consistently facing price fluctuation globally. Also, the price fluctuation is likely to increase the product cost, as well as sometimes creating product delays, which can create growth barriers for the manufacturers.

Regional Insights

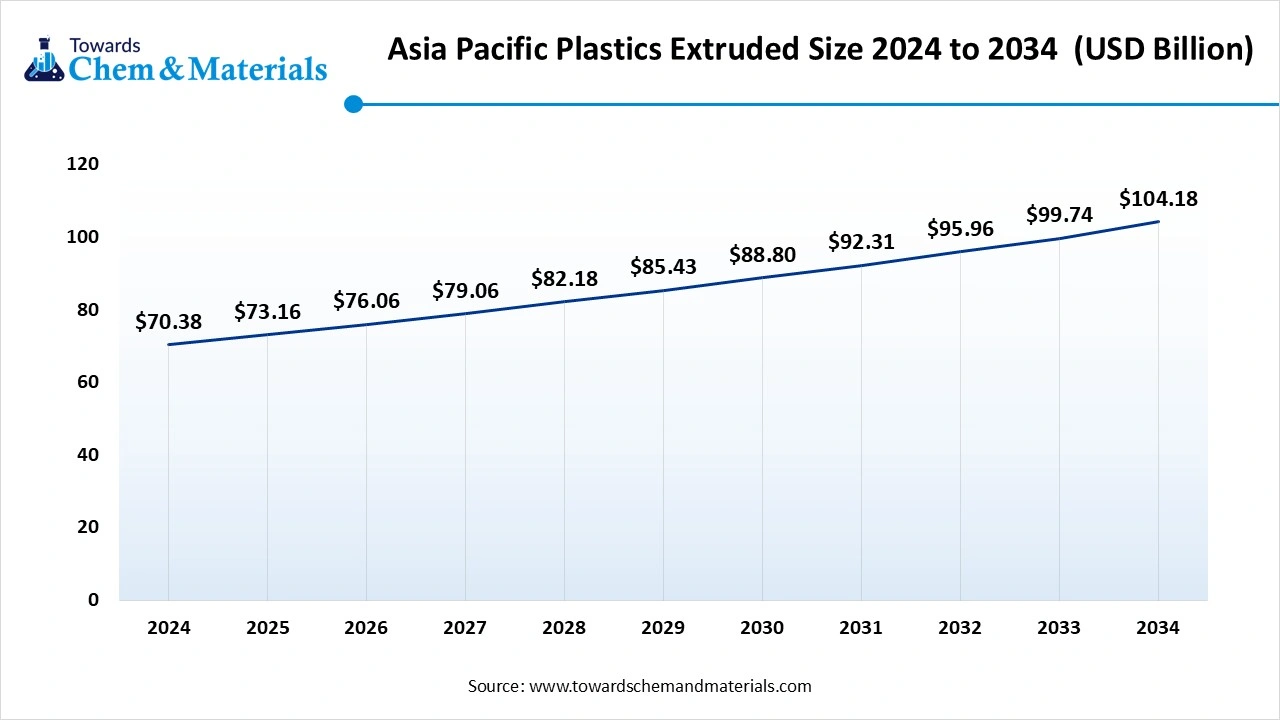

Asia Pacific

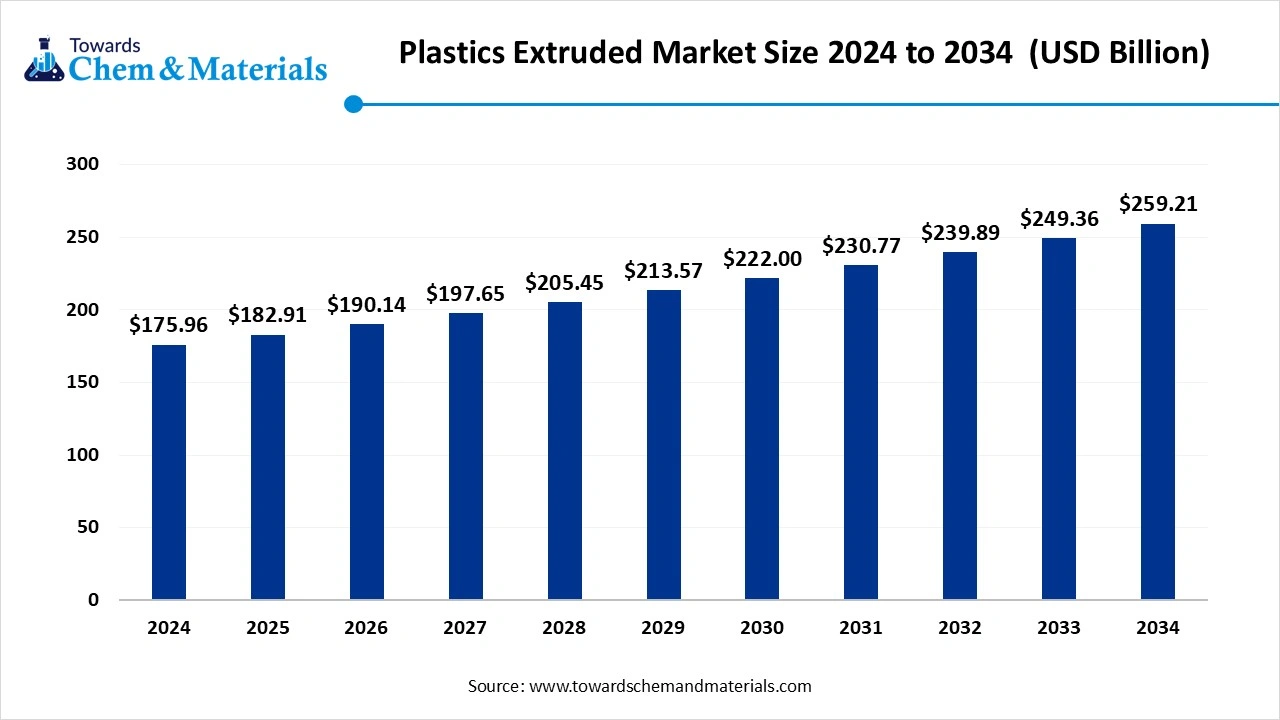

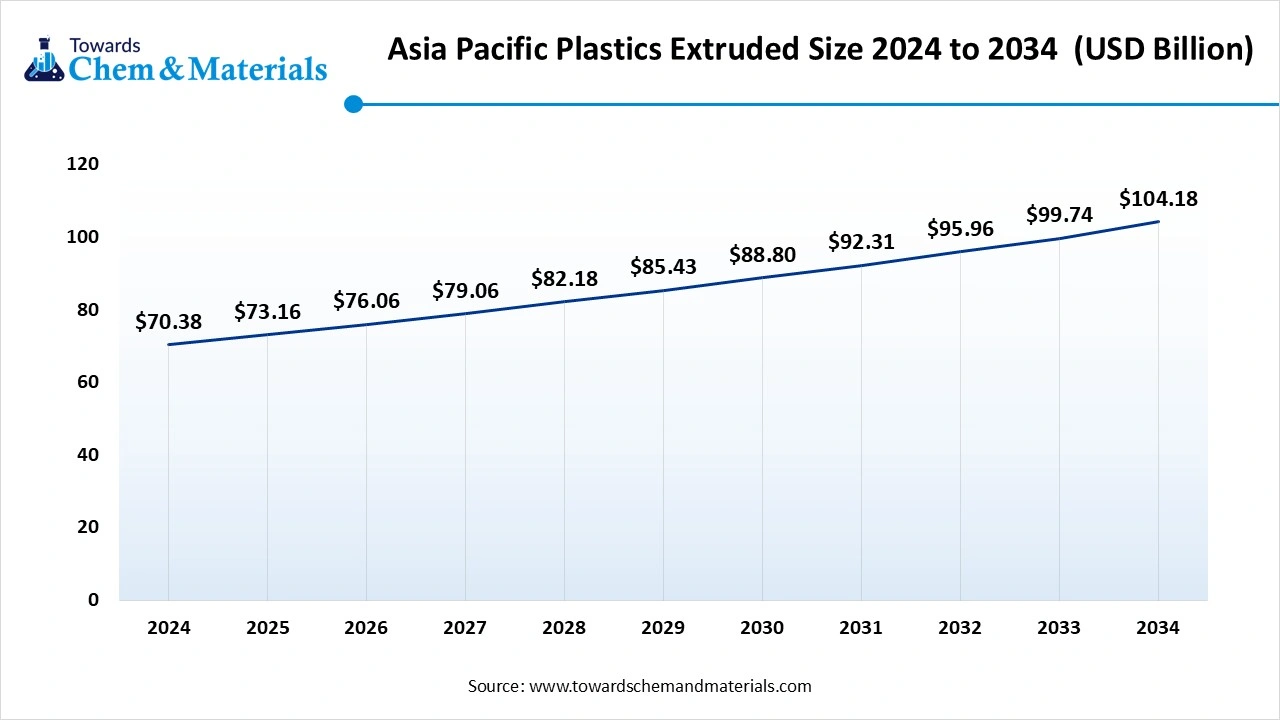

The Asia Pacific plastics extruded market size was estimated at USD 70.38 billion in 2024 and is anticipated to reach USD 104.18 billion by 2034, growing at a CAGR of 4.00% from 2025 to 2034.

Asia Pacific dominated the plastics extruded market in 2024, akin to the enlarged expansion of sectors such as packaging, automotive, and construction. Moreover, the regional countries such as India, China, and Japan have seen a heavy reliance on plastic extrusion in recent years. Moreover, the region is under rapid industrialization, where the demand for pipes, films, and profiles has increased in the past few years, as per the recent regional survey.

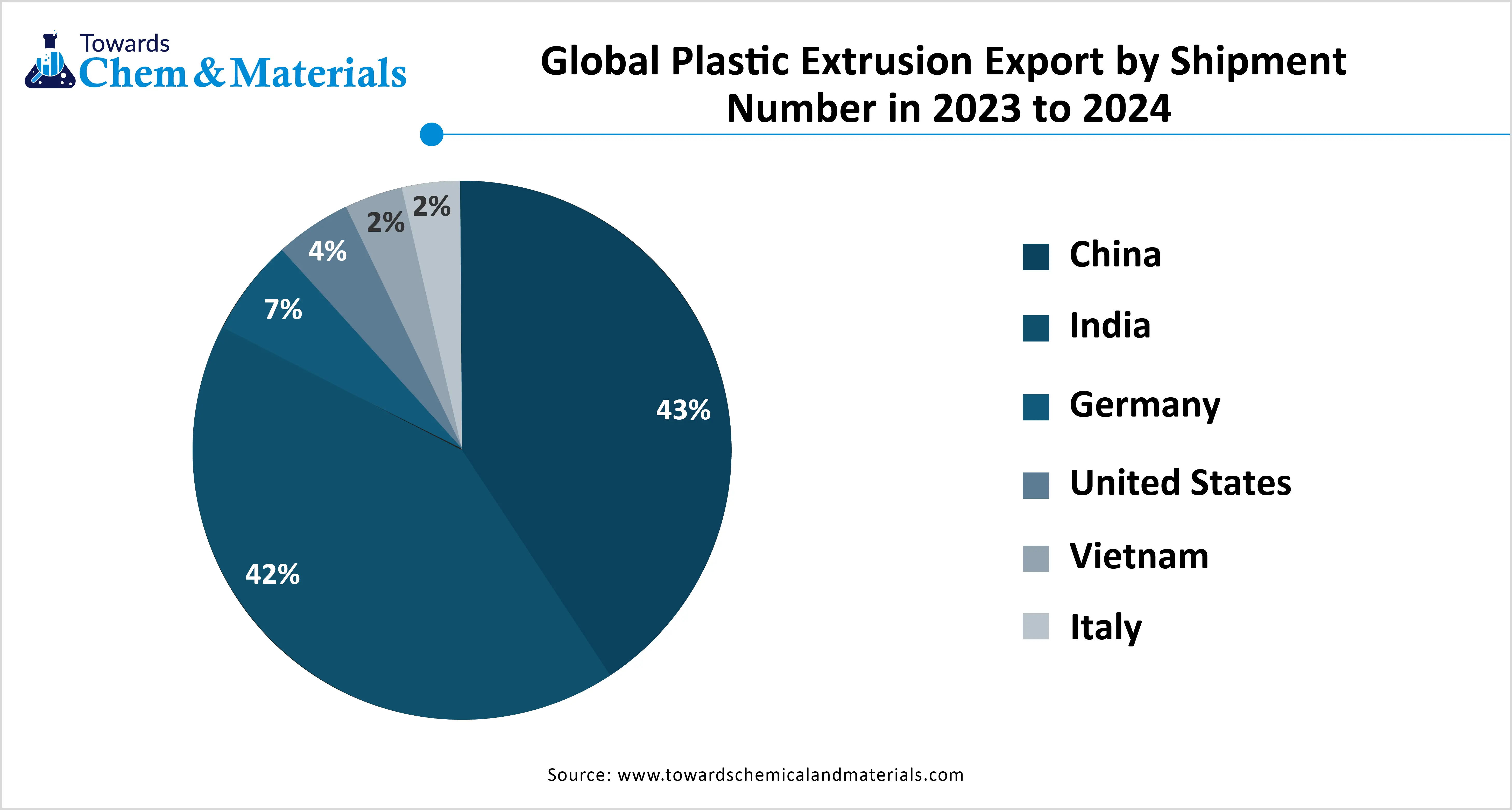

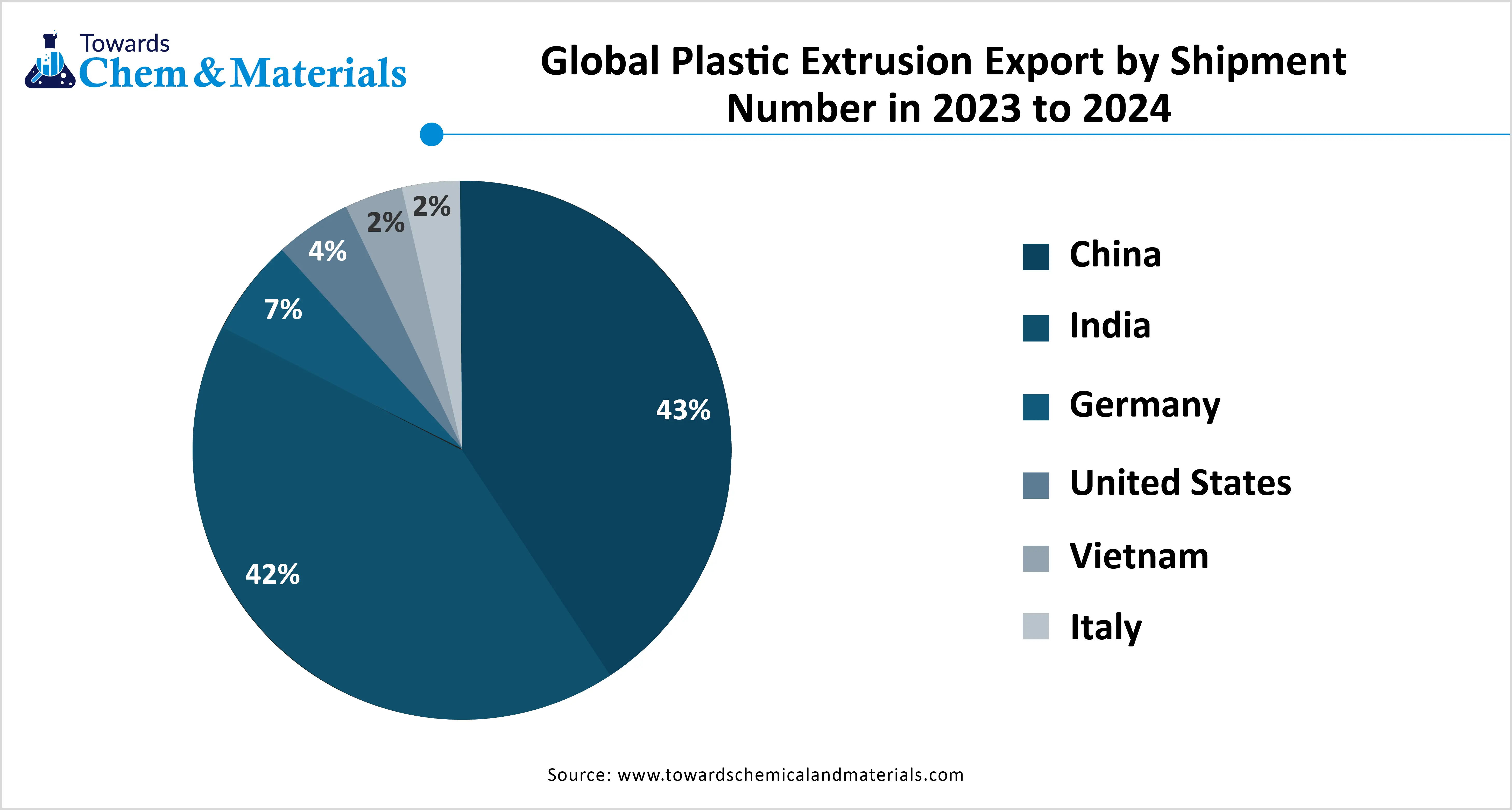

How is China’s Heavy Infrastructure Driving the Market Dominance?

China maintained its dominance in the market, owing to the presence of a heavy manufacturing infrastructure in the current period. As the country is known as one of the leading plastic product exporters, with a large consumption. Moreover, having advanced machinery and technology, the manufacturers in China have been actively developing a cost-effective and innovative product line in recent years.

North America

North America is expected to capture a major share of the plastics extruded market during the forecast period, owing to the increased need for high-quality plastic in the region nowadays. Also, having advanced technology, the region is expected to gain major market share in the upcoming years. Furthermore, the ongoing trend for sustainable packaging and energy-efficient material adoption is likely to provide a sophisticated consumer base to the manufacturer in the upcoming years.

How are Innovative Product Launches Fueling the United States' Rise?

United States is expected to rise as a dominant country in the region in the coming years, owing to the presence of technologically advanced equipment and infrastructure, where the manufacturers are actively launching innovative product lines in recent years, as per the recent survey. Furthermore, the country is actively investing in automation, which can create beneficial advantages in the upcoming years as per industry expectations.

Segmental Insights

Material Type Insights

How did the Polyethylene Extrusion Segment Dominate the Plastics Extruded Market in 2024?

The polyethylene extrusion segment held the largest share of the market in 2024, due to unique properties such as durability, versatility, and flexibility. Moreover, polyethylene is considered the ideal material to produce pipes, films, and sheets; it has maintained its dominance in recent years. Also, the high-density polyethylene has been under heavy usage in the making of construction and water pipe applications in the past few years.

The polypropylene extrusion segment is expected to grow at a notable rate during the predicted timeframe, akin to the increased need for lightweight material, and the material, which has greater resistance to fatigue and chemicals. Moreover, the sectors such as the automotive, high-performance packaging, and the medical devices are actively observed under the heavy demand for the polypropylene extrusion segment in recent years.

Process Type Insights

Why does the Single Screw Extrusion Segment Dominate the Plastics Extruded Market by Process Type?

The single screw extrusion segment held the largest share of the plastic extrusion market in 2024, due to it being considered the traditional process and its unique properties, such as the cost effectiveness and simplicity, in recent years. Moreover, this single screw process type is being used by the high-volume producer of pipes, films, and profiles. Also, having easy-to-use operating and maintenance systems, the single screw extrusion has gained immense industry attention in recent years.

The twin screw extrusion segment is expected to grow at a notable rate due to its better mixability, flexibility, and higher output as compared to the single screw systems. Moreover, these twin screw extrusions are considered the ideal solution in complex materials such as filled plastics, recycled materials, and blends, as per the recent observation. Also, the increased need for advanced plastic formulation, the twin screw extrusion is expected to gain major market share in the upcoming years, as per the future industry anticipation.

Product Type Insights

Why did the Pipes and Tubes Segment Dominate the Plastics Extruded Market in 2024?

The pipes and tubes segment dominated the market with the largest share in 2024, due to the sudden updation of the regional infrastructure globally. Several regions are seen under heavy sewage and water infrastructure development, owing to the sustainability and green building infrastructure development. Furthermore, several developers are increasingly using these pipes, such as the HDPE and PVC, as a metal alternative in the current period.

The films and sheets segments are expected to grow at a notable rate in the coming years due to rising demand in food packaging, agricultural films, medical sheets, and electronics. These products offer lightweight, flexible, and recyclable solutions for modern applications. Innovations like multi-layer films, barrier sheets, and biodegradable plastics are gaining attention. The e-commerce boom and increased consumption of packaged food are also driving this segment.

End Use Industry Insights

Why did the Packaging Segment Dominate the Plastics Extruded Market in 2024?

The packaging segment held the largest share of the plastics extruded market in 2024 due to its widespread use in consumer goods, food & beverages, and industrial applications. Plastic films and sheets are essential for flexible packaging, which protects products and extends shelf life. Extruded plastic packaging is lightweight, cost-effective, and customizable. The rise in e-commerce, online food delivery, and personal care products has significantly boosted the demand for plastic-based packaging.

The automotive segment is expected to grow at a notable rate due to the rising use of lightweight plastics to improve fuel efficiency and reduce emissions. Extruded plastic parts like trims, seals, tubing, and panels are replacing metal components. Electric vehicle (EV) production is also driving the use of advanced extruded thermoplastics for battery enclosures and cooling systems.

Equipment Type Insights

Why did the Extruders Segment Dominate the Plastic Extrusion Market in 2024?

The extruders segment dominated the market with the largest share in 2024, as they form the core of the plastic extrusion process. Whether single or twin-screw, extruders are responsible for melting and pushing plastic material through a die to shape it. Their ability to handle different types of plastics, including recycled and bio-based resins, makes them essential across all product types.

The die heads segment is expected to grow at a significant rate due to the growing demand for precision and customization in extruded products. Die heads control the final shape and quality of extruded plastics like films, tubes, and profiles. Innovations such as multi-layer co-extrusion dies, adjustable dies, and dies for complex profiles are becoming popular.

Application Type Insights

Why did the Packaging Films Segment Dominate the Plastics Extruded Market in 2024?

The packaging films segment held the largest share of the plastics extruded market in 2024, due to their extensive use in food, personal care, pharmaceuticals, and industrial packaging. These films are lightweight, protective, and offer excellent barrier properties. Extruded films are commonly used for bags, wraps, pouches, and labels. With the growing demand for hygienic and tamper-proof packaging, extruded plastic films offer efficient solutions.

The construction profile segment is expected to grow at a notable rate due to the booming global Infrastructure and housing sectors. These extruded profiles include window frames, door panels, cable ducts, and roofing components. They are favored for their strength, weather resistance, and low maintenance.

Recent Developments

- In June 2025, Clariant unveiled its latest product line of the polyer processing aids. This newly launched aid is called the AddWorks PPA. Also, it is specifically designed for the polyolefin extrusion application, as per the company's claim.(Source: www.clariant.com)

- In June 2024, JianTai introduced its latest plastic extrusion machine. Also, this machine is primarily made for recycled plastic materials, as per the report published by the company recently.(Source: www.wate.com)

Plastics Extruded Market Top Companies

- BASF SE

- SABIC

- DSM Engineering Plastics

- Dupont

- Saint-Gobain

- Makrolon®

- Michelman, Inc.

- Leistritz Extrusionstechnik GmbH

- Nordson Corporation

- Prism Plastics Inc.

- Jain Irrigation Systems Ltd.

- PolyOne Corporation

- Aluplast GmbH

- U.S. Plastic Corp.

- Zeus Industrial Products

- WITTMANN BATTENFELD

- Graham Engineering Corporation

- Coperion GmbH

- The Dow Chemical Company

- Reifenhäuser GmbH

Segment Covered

By Material Type

- Polyethylene (PE) Extrusion

- Polyvinyl Chloride (PVC) Extrusion

- Polypropylene (PP) Extrusion

- Polystyrene (PS) Extrusion

- Acrylonitrile Butadiene Styrene (ABS) Extrusion

- Polycarbonate (PC) Extrusion

- Others (Polyamides, PET, etc.)

By Process Type

- Single-Screw Extrusion

- Twin-Screw Extrusion

- Ram Extrusion

- Micro-Extrusion

- Co-extrusion

- Blown Film Extrusion

- Injection Extrusion

By Product Type

- Films & Sheets

- Pipes & Tubes

- Profiles & Molding

- Compounds & Granules

- Wires & Cables

- Others (Fittings, Geomembranes)

By End-Use Industry

- Construction

- Packaging

- Automotive

- Electronics

- Medical & Healthcare

- Consumer Goods

- Agriculture

- Others (Textiles, Aerospace)

By Equipment Type

- Extruders

- Die Heads

- Cooling Systems

- Cutters

- Others (Mixers, Conveyors)

By Application

- Packaging Films

- Construction Profiles

- Automotive Parts

- Medical Tubing

- Agricultural Films

- Electrical Insulation

- Others (Flooring, Furniture)

By Region

- North America

- U.S.

- Mexico

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Asia Pacific

- China

- India

- Japan

- South Korea

- Central & South America

- Brazil

- Argentina

- Middle East & Africa

- Saudi Arabia

- UAE