Content

What is the Current Polyether Ether Ketone Market Size?

The global polyether ether ketone market size was USD 1.89 billion in 2025 and is predicted to increase from USD 2.03 billion in 2026 and is expected to be worth around USD 3.91 billion by 2035, growing at a CAGR of 7.55% from 2026 to 2035. Asia Pacific dominated the polyether ether ketone market with the largest revenue share of 45.11% in 2025.The growing demand across various industries like medical applications, electronics, healthcare, and semiconductors drives the growth of the market.

Market Highliights

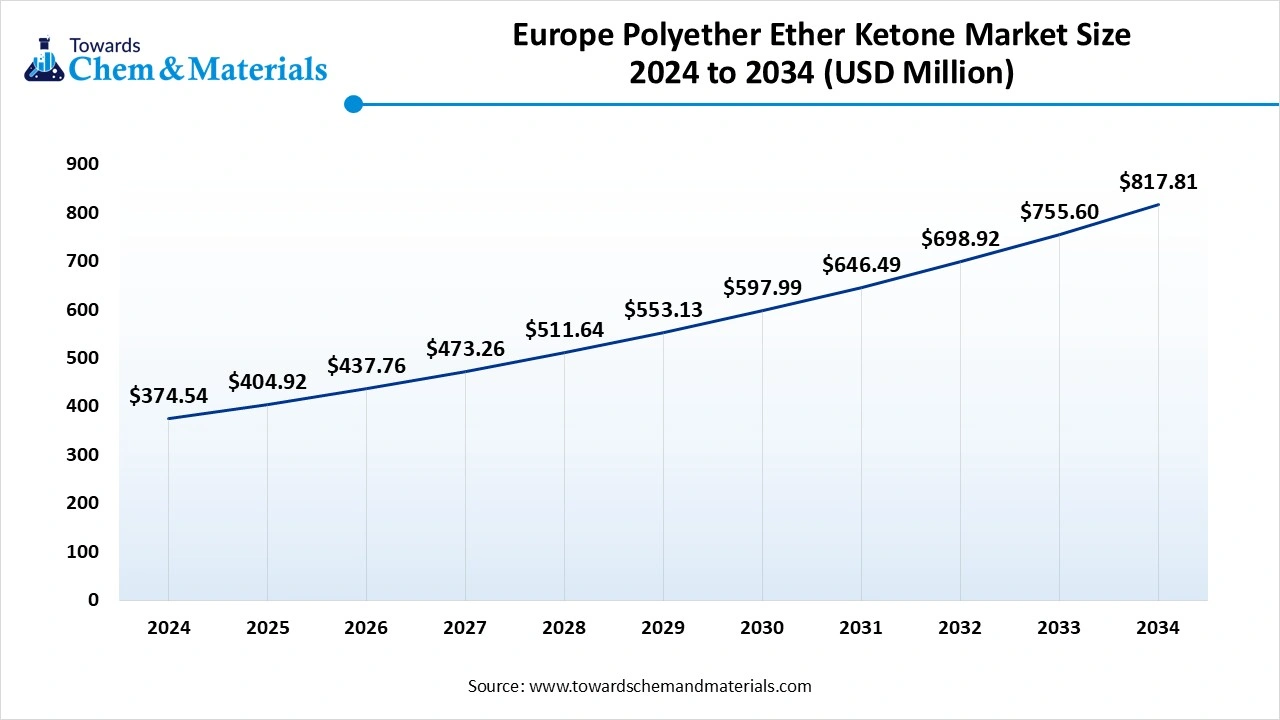

- The Europe dominated the global polyether ether ketone market with the largest volume share of 45.11% in 2025.

- By product, the carbon-filled segment dominated the market and accounted for the largest volume share of 49.18% in 2025.

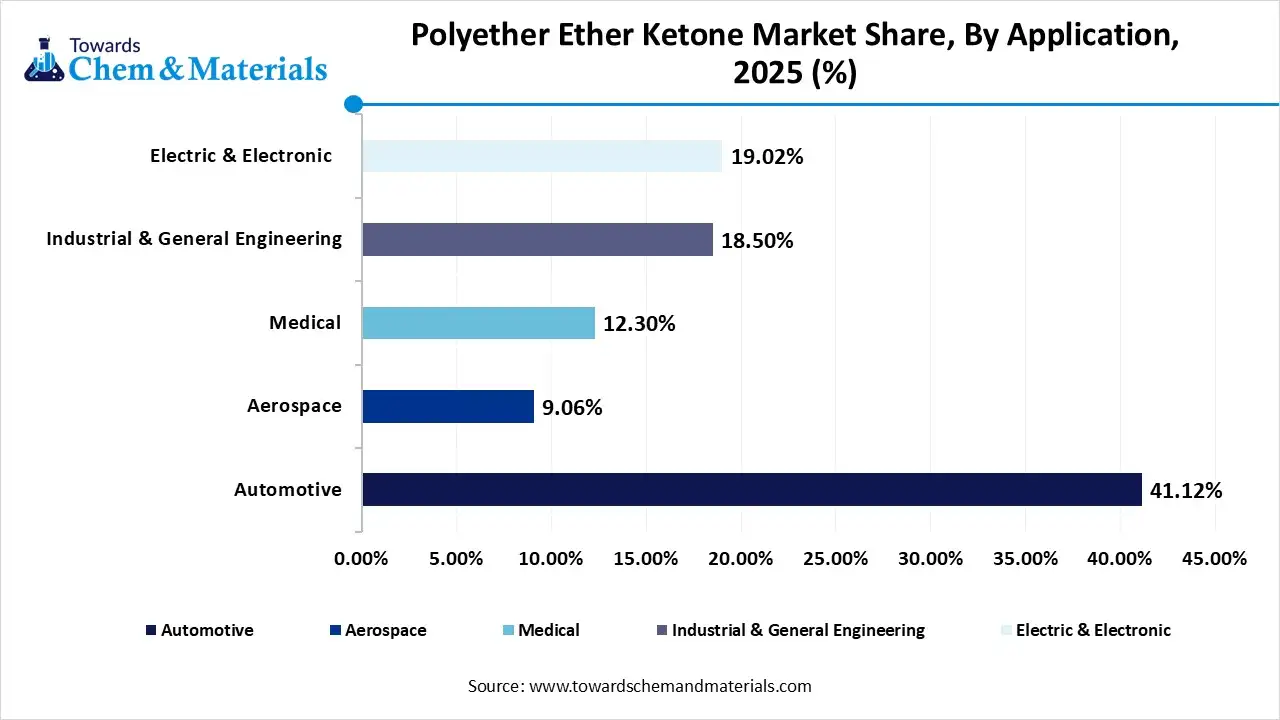

- By application, the automotive segment led the market with the largest revenue volume share of 41.12% in 2025.

PEEK: Game Changer for High-Tech Applications and Modern Industry

Polyether ether ketone, known as PEEK, is an organic thermoplastic polymer with excellent thermal and mechanical properties. It is produced by step-growth polymerization techniques. It offers excellent resistance to radiation damage, thermal degradation, and chemical degradation. It consists of high mechanical properties like toughness, strength, and stiffness. PEEK is biocompatible, non-biodegradable, and has high temperature resistance. It is widely used in applications like piston parts, high-performance liquid chromatography columns, electrical cable insulation, bearings, pumps, and compressor plate valves. The growing demand for high-performance materials in various applications fuels the adoption of PEEK.

The growing advancements in PEEK manufacturing technologies help in the market growth. The growing advancements in 3D printing increase demand for PEEK to manufacture complex components and parts. The strong focus on sustainability fuels demand for PEEK due to its recyclability. The growing demand from various industries like healthcare, oil & gas, automotive, semiconductor, aerospace, and electronics contributes to the polyether ether ketone market growth.

- DONGGUAN WANLIHUA TRADE CO LTD is the leading supplier of polyether ether ketone in the world.(Source:Volza)

- The United States exported 26961 shipments of PEEK.(Source: Volza )

- Vietnam exported 24293 shipments of PEEK.(Source: Volza )

- The United States exported 1422 shipments of PEEK fittings.(Source:Volza)

The Growing Demand from the Electronics & Semiconductor Industry

The growing expansion of the electronics and semiconductor industry in various regions fuels demand for polyether ether ketone due to its lightweight nature and high performance. The growing demand for various electronic devices like smartphones, laptops, computers, and wearable devices increases the demand for PEEK. The growing advancements in electronic devices, like miniaturization and compact devices, increase demand for PEEK materials to minimize overall product weight. The rising demand for various electronics components like insulators, semiconductor manufacturing, connectors, and wire coating is driving demand for PEEK for the longevity of devices. The growing demand for smart devices and the expansion of 5G technology fuel demand for high-performance materials like PEEK.

The increasing demand for semiconductor manufacturing in the semiconductor industry fuels demand for PEEK due to its excellent mechanical stability and chemical resistance. The growing demand for semiconductor manufacturing, like printed circuit boards, wafer handling, and manufacturing equipment, helps in the market growth. The growing demand from the electronics and semiconductor industry is a key driver for the growth of the polyether ether ketone market.

Market Trends

- Growing demand for lightweight & high performance materials:- The growing demand for lightweight and high-performance materials in various industries increases demand for PEEK for different applications. The growing demand for lightweight materials in the automotive and aerospace industry for enhancing fuel efficiency increases the demand for PEEK. The growing demand from the electrical, medical devices, and electronics industry helps in the market growth.

- Technological advancements in manufacturing technologies:- The growing advancements in PEEK manufacturing, like 3D printing and cost-effective production, help in the expansion of the market. The advancements in manufacturing technologies make it accessible to diverse industries.

- The growing demand for minimally invasive procedures:- The growing demand for minimally invasive procedures, like transfemoral heart valve implementation, interbody cages, catheters, and stents, increases demand for PEEK due to its radiolucency and biocompatibility.

Report Scope

| Report Attributes | Details |

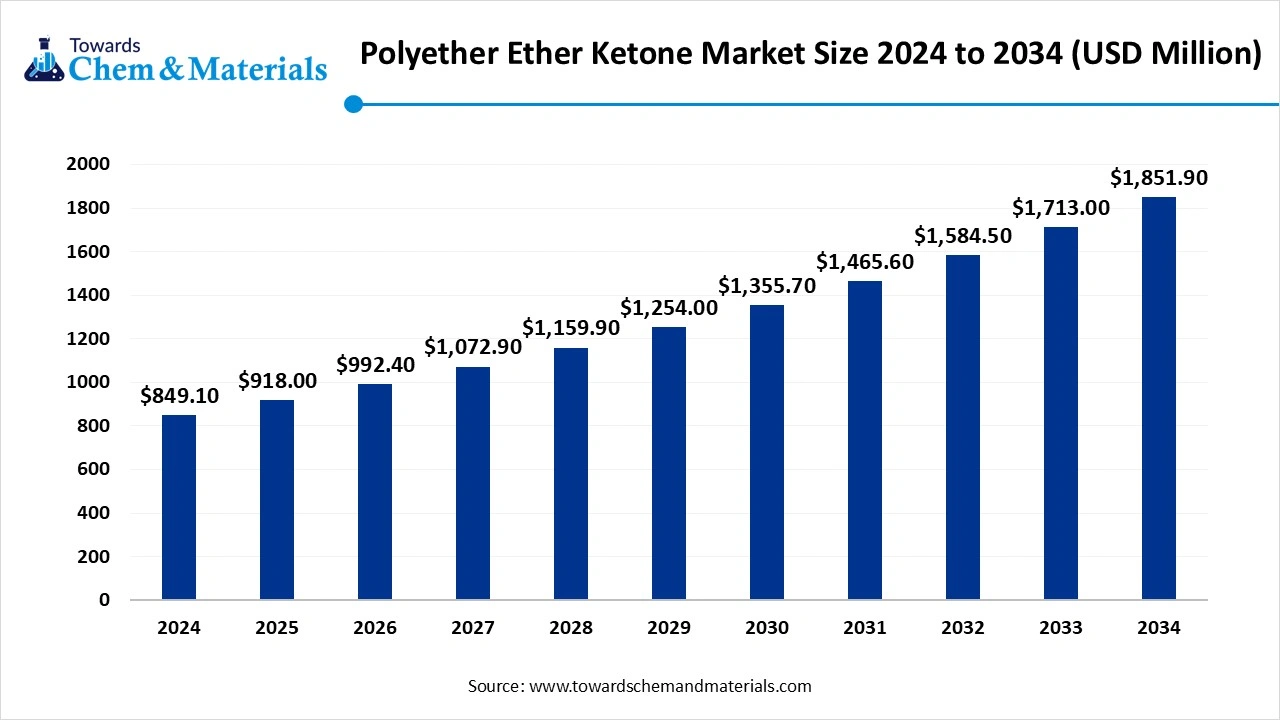

| Market Size in 2025 | USD 918.0 million |

| Market Size by 2034 | USD 1,851.90 million |

| Growth Rate from 2025 to 2034 | CAGR 8.11% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| High Impact Region | Europe |

| Segment Covered | By Product, By Application, By Region |

| Key Companies Profiled | Caledonian Industries Ltd., Saudi Basic Industries Corporation, A. Schulman, Inc., Victrex plc, Celanese Corporation, Parkway Products, LLC, J. K. Overseas, Evonik Industries AG, Cytec Solvay Group, Ensinger GmbH |

Market Dynamics

Market Drivers

The polyether ether ketone market is driven by rising demand for high-performance polymers that can withstand extreme temperatures, chemical exposure, and mechanical stress across aerospace, automotive, medical, electronics, and industrial applications. Increasing lightweighting requirements in aircraft structures, automotive powertrain components, and electric vehicle systems are accelerating the substitution of metal parts with PEEK due to its high strength-to-weight ratio and fatigue resistance.

In the medical sector, strong adoption of PEEK in spinal implants, trauma fixation devices, and dental components is supported by its biocompatibility, radiolucency, and resistance to repeated sterilization cycles. Growth in semiconductor manufacturing and electronics assembly is also increasing demand for PEEK-based components that offer dimensional stability and low outgassing in high-temperature and cleanroom environments. Together, these performance-driven requirements are reinforcing sustained demand across end-use industries.

Market Restraints

The PEEK market is restrained by its high material and processing costs compared to conventional engineering plastics, which can limit adoption in price-sensitive applications. Manufacturing challenges such as narrow processing windows, high melt temperatures, and the need for specialized equipment increase production complexity and capital requirements.

Limited availability of raw materials and dependence on a relatively small number of qualified suppliers can expose the market to supply chain risks. In some applications, alternative high-performance polymers or metal alloys may offer sufficient performance at lower cost, reducing the incentive to shift to PEEK. Regulatory approval timelines, particularly in medical and aerospace applications, can further delay commercialization of new PEEK-based components.

Market Opportunities

Opportunities in the PEEK market are expanding with the rapid growth of electric vehicles, renewable energy systems, and advanced manufacturing technologies. Increased use of PEEK in battery insulation, connectors, and thermal management components supports electrification trends that demand high thermal and electrical performance. Additive manufacturing and advanced compounding techniques are opening new design possibilities for complex, lightweight, and customized PEEK components.

In healthcare, rising demand for patient-specific implants and minimally invasive procedures is increasing interest in PEEK materials that can be tailored for imaging compatibility and long-term implantation. Emerging applications in hydrogen systems, oil and gas exploration, and high-performance filtration further broaden the market’s long-term growth potential.

Market Challenges

Key challenges for the PEEK market include scaling production capacity while maintaining consistent material quality and performance standards across applications. Technical expertise is required to optimize processing parameters, part design, and post-processing to fully realize PEEK’s performance advantages, which can limit adoption among smaller manufacturers. Ensuring compliance with strict regulatory and certification requirements across aerospace, medical, and energy sectors adds to development time and cost. Market education remains a challenge, as end users may lack familiarity with lifecycle cost benefits compared to traditional materials. Addressing these technical, regulatory, and awareness-related barriers is critical for broader penetration of PEEK across high-growth end-use industries.

Value Chain Analysis

- Raw Material and Monomer Production: This involves the production of key chemical precursors, such as 4,4'-difluorobenzophenone, required for PEEK synthesis.

- Key Players: Victrex, Solvay, and Evonik.

- Polymerization and Resin Manufacturing: In this, monomers are synthesized through a step-growth polymerization process to create PEEK polymer resin in various forms like pellets, powder, and granules.

- Key Players: Victrex plc, Syensqo, Evonik Industries AG, Jilin Joinature Polymer Co., Ltd., and Panjin Zhongrun High Performance Polymer Co., Ltd.

- Processing and Component Manufacturing: In this, PEEK resin is converted into semi-finished shapes and high-precision parts using processing methods like injection molding, extrusion, and additive manufacturing.

- Key Players: Ensinger GmbH, Mitsubishi Chemical Advanced Materials, and Drake Plastics.

- End-User Application and Integration: In this, PEEK components are integrated into final products and systems across diverse high-performance industries.

- Key Players: Victrex PEEK-OPTIMA and Evonik's VESTAKEEP.

Segmental Insights

Product Insights

Which Product Segment Dominate the Polyether Ether Ketone Market in 2024?

The carbon-filled segment dominated the market and accounted for the largest volume share of 49.18% in 2025. The growing demand from various industries like electronics, aerospace, medical, and automotive helps in the market growth. Carbon-filled enhances the stiffness and mechanical strength of PEEK. It is highly durable even at high temperatures and minimizes wear & tear of components like seals, bearings, and gears. The growing demand for electronic components increases the adoption of carbon-filled PEEK to enhance heat dissipation. The growing demand from electrical & electronic applications to enhance electrical conductivity helps in the growth of the market growth. The growing demand for structural parts & engine components in the automotive and aerospace industry increases demand for carbon-filled PEEK, driving the overall growth of the market.

The glass-filled segment is the fastest-growing in the market during the forecast period. The growing demand from industrial sectors to enhance reliability & durability helps in the market growth. The growing need for durable & lightweight materials to enhance efficiency and performance increases demand for glass-filled PEEK materials. The growing demand for housing, connectors, and switches in the electronics & electrical industry fuels demand for glass-filled PEEK. The growing demand from the oil & gas sector and under-the-hood applications helps in the market growth. The growing demand for durable & lightweight parts like seals and gears in the automotive & aerospace industry fuels demand for PEEK, driving the overall growth of the market.

Application Insights

Why Did The Automotive Segment Dominate the Polyether Ether Ketone Market?

The automotive segment led the market with the largest revenue volume share of 41.12% in 2025. The growing demand for electric vehicles in various regions increases the demand for PEEK for components like wire insulation & battery housing. The growing demand for lowering fuel emissions and lightweight components for vehicles helps in the market growth. The growing automotive sector increases demand for engine components, fueling demand for PEEK. The growing demand for durable components in automotive applications increases the adoption of PEEK. The regulatory pressure for improving fuel efficiency fuels demand for PEEK. The growing expansion of the automotive industry in various countries drives the overall growth of the market.

The aerospace segment experiences the fastest growth in the market during the forecast period. The strong focus of the aerospace industry on lowering environmental impact increases demand for the market. PEEK lowers emissions and enhances the fuel efficiency of aerospace. The growing demand for high-performance aerospace components helps in the market growth. The growing demand from various aerospace applications like landing gear seals, interior components, and engine parts helps in the market growth. The rapid expansion of the aerospace industry fuels demand for high-strength & lightweight materials, contributing to the PEEK market growth.

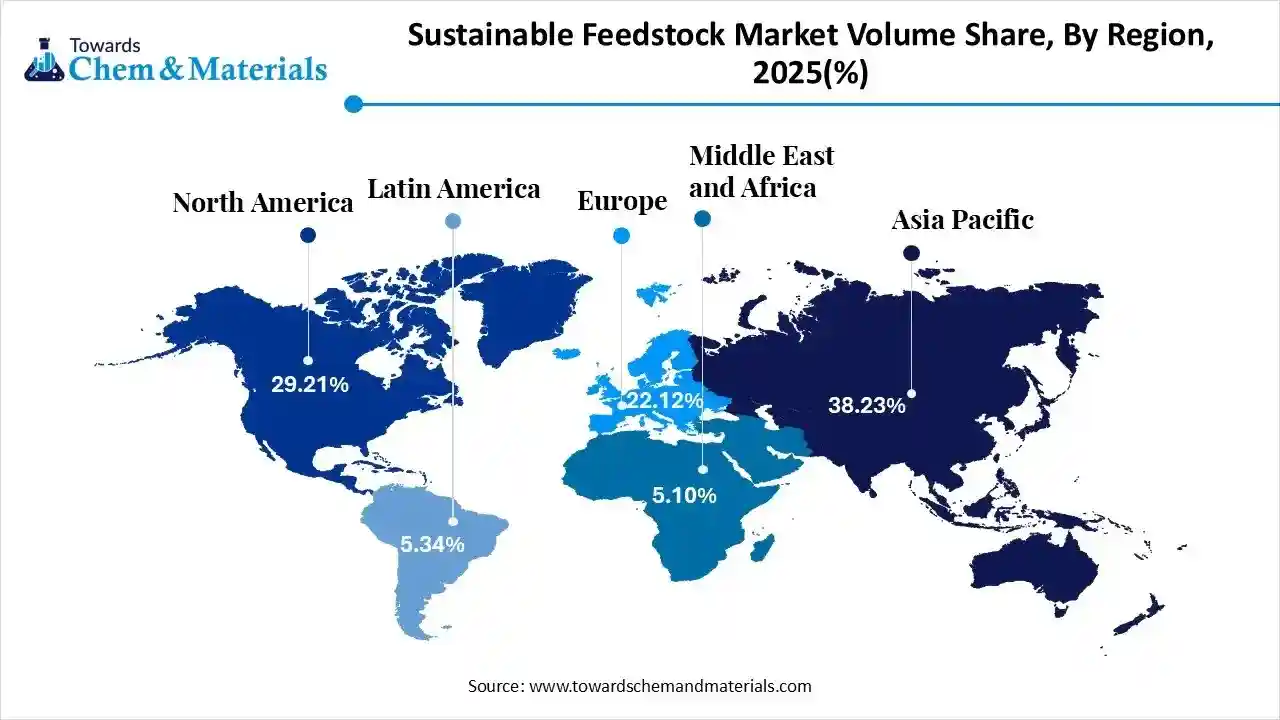

Regional Insights

The polyether ether ketone market size was valued at USD 0.85 billion in 2025 and is expected to be worth around USD 1.76 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 7.57% over the forecast period from 2026 to 2035.

The well-established automotive industry and robust aerospace industry increase demand for polyether ether ketone. The stringent environmental regulations and growing demand in the transportation sector help in the market growth. The strong focus on lightweight materials and recyclability fuels demand for PEEK. The growing demand for surgical instruments and medical implants increases the demand for PEEK. The well-established manufacturing capabilities and growing consumption of PEEK in countries like the UK and Germany drive the market growth. The thriving healthcare industry increases the consumption of PEEK for various healthcare processes. Additionally, the presence of major manufacturers like Evonik Industries AG and Victrex plc drives the overall growth of the market.

Industrial Sector Driving Demand for PEEK in Germany

Germany is significantly growing in the polyether ether ketone market. The well-established industrial base in the machinery, automotive, and aerospace sectors increases demand for polyether ether ketone. The growing demand from the aerospace industry due to high strength & temperature resistance helps in the market growth. The rising industrial machinery applications, like the impeller wheel, increase demand for PEEK. The growing innovation in the automotive & aerospace industry and focus on high-tech manufacturing equipment drive the market growth. The growing adoption of electric vehicles and a strong focus on sustainable manufacturing support the overall growth of the market.

- Germany exported 388 shipments of PEEK disks.(Source:Volza )

- Germany exported 493 shipments of PEEK fittings.(Source:Volza)

Why is Asia Pacific Growing in the Polyether Ether Ketone Market?

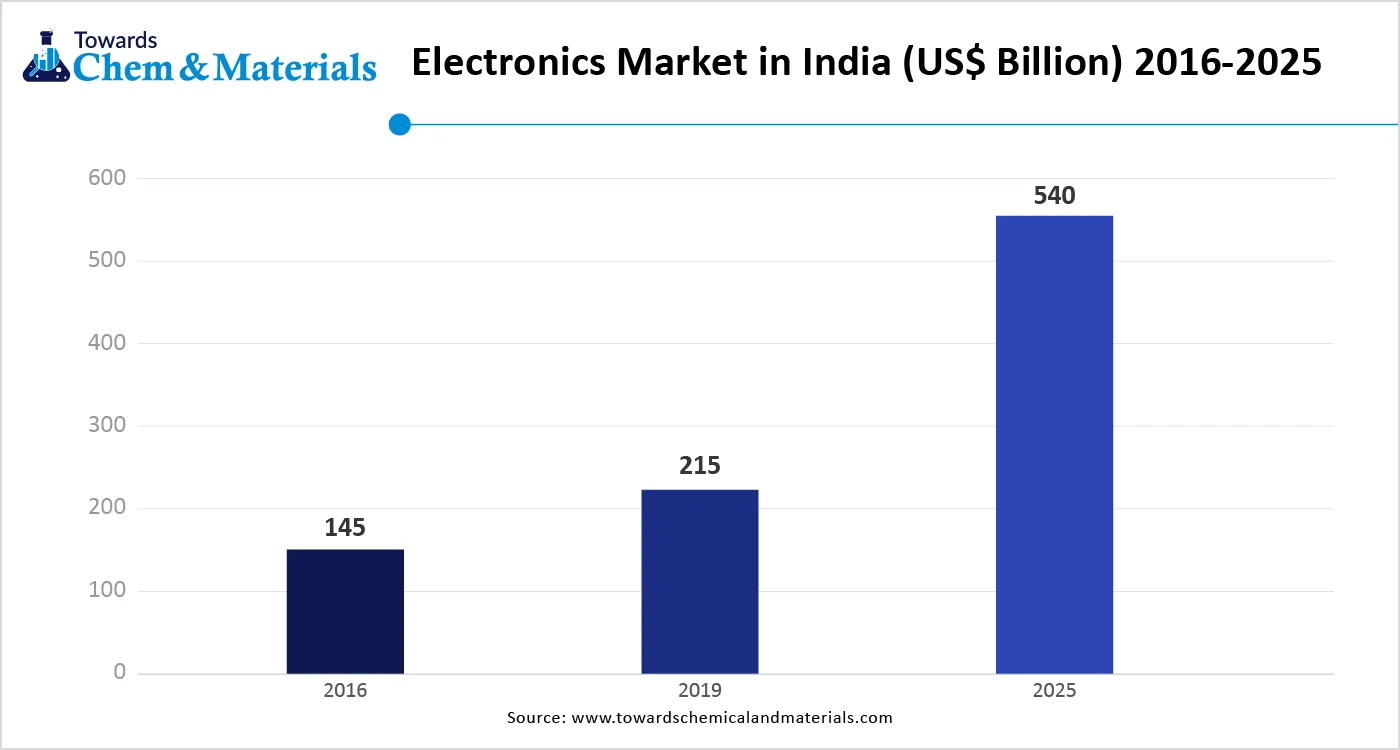

Asia Pacific experiences the fastest growth in the market during the forecast period. The strong industrial base in various countries increases demand for PEEK for various sectors. The growing demand from sectors like healthcare, aerospace, and electronics, due to properties like biocompatibility, high heat resistance, and high chemical resistance, helps in the market growth. The strong focus on advanced technologies and investment in research & development by companies increases demand for PEEK. The growing expansion of the electronic & electrical sector in countries like India and China drives the market growth.

The presence of a strong manufacturing base and growing demand from various medical applications helps in the market growth. Additionally, the growing automotive industry, increasing demand from the healthcare sector, and the rise of electric vehicles contribute to the market growth.

China’s Polyether Ether Ketone Market Trends

China dominated the polyether ether ketone market in Asia Pacific. The rapid growth of the automotive industry and the growing focus on electric vehicles increase demand for PEEK. The growing domestic production and technological advancements help in the market growth. The growing demand for medical devices and 5G technology increases demand for the market. The growing expansion of the electronic industry increases demand for PEEK for high-performance applications, driving the overall growth of the market.

- China exported 118 shipments of polyether ether ketone.(Source: Volza)

- China exported 888 shipments of PEEK rod.(Source: Volza)

What are the Growth Factors for the Polyether Ether Ketone Market in India?

India is significantly growing in the polyether ether ketone market. The well-established manufacturing sector for high-performance components increases demand for PEEK. The growing demand from the automotive and electronics industry helps in the growth of the market. The government initiatives, like Make in India, for domestic production and technological advancements in PEEK-based materials, drive market growth. The growth in the defense and aerospace sector increases demand for PEEK contributes to the overall market growth.

- India exported 33143 shipments of PEEK.(Source: Volza)

Why did Latin America become a Notable Region in the Polyether Ether Ketone Market?

North America is notable in the global market, primarily due to the strong presence of key industries such as aerospace, medical, and automotive, along with an environment that promotes technological innovation and R&D. The advanced healthcare sector, especially in the U.S. and Canada, relies heavily on PEEK for specialized applications, including spinal and orthopedic implants, due to its biocompatibility and ability to be sterilized. Government initiatives and funding, such as the USMCA-led supply chain reshoring incentives and investments in semiconductor manufacturing, further encourage domestic production and the adoption of advanced materials.

U.S. Polyether Ether Ketone Market Trends

The U.S. plays a dominant role as a key market, driven mainly by robust demand across various high-tech industries. This demand is significantly concentrated in sophisticated applications where high performance is essential. Major global manufacturers, such as Solvay and Evonik, maintain a strong presence and have facilities in the U.S. The country is a primary consumer of PEEK for implantable devices like spinal fusion cages and dental implants, given its biocompatibility and radiolucency.

Emergence of Latin America in the Polyether Ether Ketone Market

Latin America is also experiencing notable growth in the global market, largely due to the expansion and modernization of its automotive, medical, and oil & gas industries, along with the increasing adoption of advanced manufacturing technologies like 3D printing. Government initiatives in countries such as Brazil and Argentina, including local content regulations in the automotive and offshore oil sectors, promote the use of local polymer equivalents, stimulating the domestic market. PEEK is favored for pipeline linings, seals, and valve systems in these challenging environments.

Brazil Polyether Ether Ketone Market Trends

Brazil stands out as a prominent and growing market within Latin America, focusing on local industrial development and specific high-growth sectors. The market is primarily driven by industrial modernization, government incentives, and efforts to replace imported metal parts with local polymer alternatives. PEEK is particularly useful in demanding environments for components such as seals and pumps, owing to its resistance to pressure and heat.

How will the Middle East and Africa contribute to the Polyether Ether Ketone Market?

The Middle East and Africa are significant contributors to the global market, primarily because of the material's exceptional properties, including high thermal stability, chemical resistance, and mechanical strength, which make it an excellent alternative to traditional materials like metal. Countries such as the UAE and Saudi Arabia are investing heavily in large-scale infrastructure and smart-city projects that require high-specification, durable materials for various applications, including utility conduits. The adoption of advanced manufacturing processes like injection molding and 3D printing in the region is enhancing production efficiency.

UAE Polyether Ether Ketone Market Trends

The UAE is a high-growth market within the region, primarily due to its adoption of PEEK in semiconductor fabrication and solar-thermal installations, where its durability and UV resistance are highly valued. Additionally, it is leveraging PEEK for lightweight aircraft components and the 3D printing of flight-certified brackets to reduce maintenance time, owing to the material's durability and UV resistance.

Recent Developments

- In August 2025, researchers from the Astana IT University conducted a study showing that CoCr-filled PEEK can deliver markedly improved hardness and wear resistance while retaining thermal properties and frictional behavior comparable to neat PEEK, making these composites strong candidates for high-load, wear-critical applications.(Source: www.nature.com)

- In July 2025, scientists from the Dalian Maritime University conducted research utilizing material extrusion additive manufacturing technology to fabricate polyether-ether-ketone (PEEK) based on triply periodic minimal surface (Gyroid) structures and three-dimensional plate-like lattice structures (BCC and FCC). (Source: www.sciencedirect.com)

Top Companies List

- Caledonian Industries Ltd.

- Saudi Basic Industries Corporation

- A. Schulman, Inc.

- Victrex plc

- Celanese Corporation

- Parkway Products, LLC

- J. K. Overseas

- Evonik Industries AG

- Cytec Solvay Group

- Ensinger GmbH

Segments Covered

By Product

- Carbon Filled

- Glass Filled

- Unfilled

By Application

- Automotive

- Aerospace

- Medical

- Industrial & General Engineering

- Electric & Electronic

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East & Africa

- South Africa

- UAE

- Saudi Arabia

- Kuwait