Content

Epoxy Resins Market Size and Share 2034

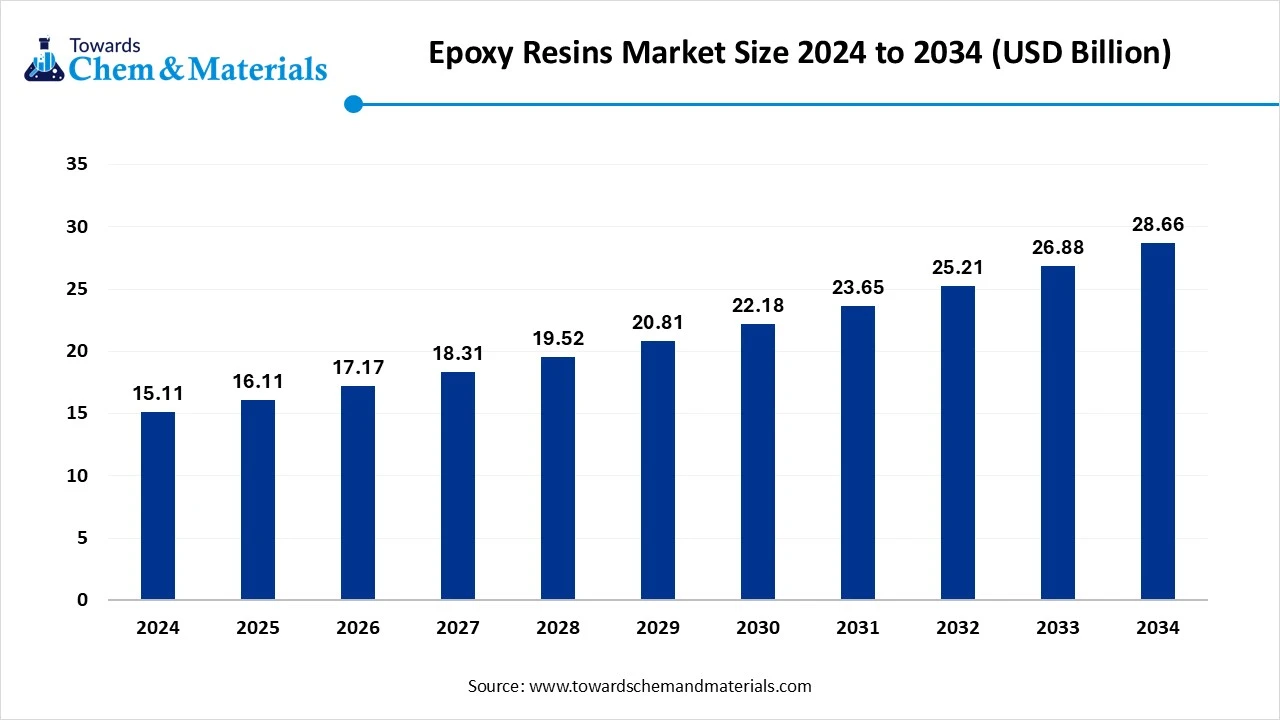

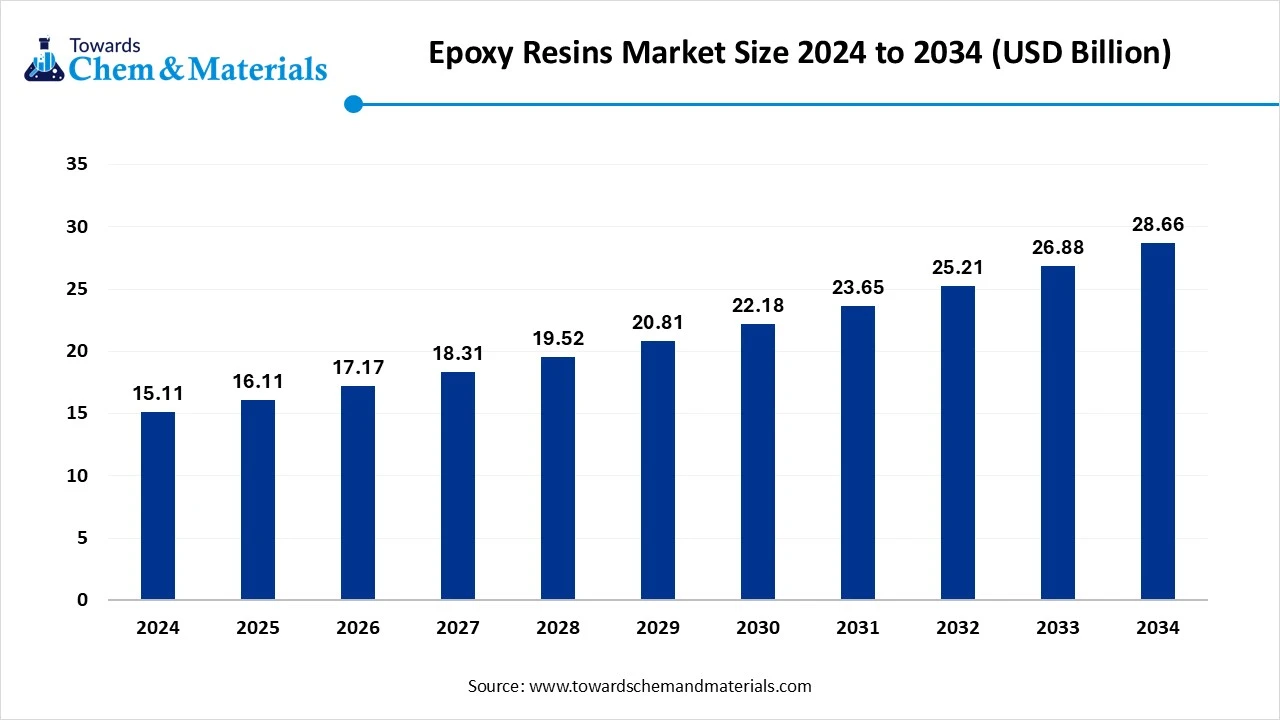

The global epoxy resins market size was reached at USD 15.11 billion in 2024 and is expected to be worth around USD 28.66 billion by 2034, growing at a compound annual growth rate (CAGR) of 6.61% over the forecast period 2025 to 2034. The growth of the market is driven by the growing infrastructure development projects and rapid industrialization, which further fuel the growth of the market.

Key Takeaways

- By region, Asia Pacific dominated the market in 2024. The North America region held a 50% share in the market in 2024. Rapid industrialization and urbanization fuel the growth of the market.

- By region, North America is expected to have significant growth in the market in the forecast period. The growing demand for materials fuels the growth of the market.

- By physical form, the liquid epoxy resins segment dominated the market in 2024. The liquid epoxy resins segment held a 60% share in the market in 2024. The growth is driven by the excellent properties offered.

- By physical form, the solid epoxy resins segment is expected to grow significantly in the market during the forecast period. Growing demand from the electronics sector fuels the growth of the market.

- By type, the bisphenol-A-epoxy resins segment dominated the market in 2024. The bisphenol-A-epoxy resins segment held a 50% share in the market in 2024. The mechanical strength and strong adhesion drive the growth.

- By type, the novolac epoxy resins segment is expected to grow in the forecast period. The use in high-performance coating makes it a preferred choice.

- By raw material, the bisphenol-A segment dominated the market in 2024. The bisphenol-A segment held a 55% share in the market in 2024. High transparency, strong adhesion also fuel the growth of the market.

- By raw material, the bisphenol-F segment is expected to grow in the forecast period. Expanding demand to enhance performance drives the growth of the market.

- By application, the paints & coatings segment dominated the market in 2024. The paints & coatings segment held a 35% share in the market in 2024. The growing construction activity influences the growth.

- By application, the wind energy components segment is expected to grow in the forecast period. The growing focus on environmental sustainability supports the growth.

- By end use, the building & construction segment dominated the market in 2024. The building & construction segment held a 40% share in the market in 2024. The growing construction activity and demand for materials fuel the growth.

- By end use, the renewable energy segment is expected to grow in the forecast period. The lightweight, aerial demand increases the growth of the market.

Market Overview

Rising Demand for Durable Materials: Epoxy Resins Market to Expand

The epoxy resins market refers to the global industry involved in the production, distribution, and application of epoxy resins, thermosetting polymers formed from the reaction between epoxide groups and curing agents. These resins are valued for their exceptional adhesion, chemical resistance, mechanical strength, and versatility, making them integral in coatings, adhesives, composites, electronics, and construction applications.

What Are the Key Growth Drivers That Support the Growth of the Epoxy Resins Market in 2024?

The growth of the market is driven by the growing industries and rapid industrialization, like high-performance industries, aerospace, automotive, and construction, which demand high-strength materials that are durable and lightweight, which helps improve the performance and resists various environmental factors, which fuels the growth of the market.

The infrastructure development projects, and government contracts contribute to the larger demand for epoxy resins due to their properties, which boost the growth of the market. The key properties, like lightweighting and performance enhancement, make it a preferred choice to produce composite materials, which fuels the growth and expansion of the market.

Report Scope

| Report Attribute | Details |

| Market Size in 2025 | USD 16.11 billion |

| Expected Size by 2034 | USD 28.66 billion |

| Growth Rate from 2025 to 2034 | CAGR 6.61% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Physical Form, By Type, By Raw Material, By Application, By End-Use Industry, By Region |

| Key Companies Profiled | Hexion Inc. , Olin Corporation, Huntsman Corporation, Nan Ya Plastics Corporation, Kukdo Chemical Co., Ltd. , Aditya Birla Chemicals , Chang Chun Group , Jiangsu Sanmu Group Co., Ltd. , Sinopec Baling Company Limited , Westlake Epoxy (Westlake Chemical Corporation) , 3M Company , Spolchemie , Atul Ltd. , NAGASE ChemteX Corporation, LEUNA-Harze GmbH , AnQore B.V. , Emerald Performance Materials LLC , DIC Corporation , Mitsubishi Chemical Corporation, Sumitomo Bakelite Co., Ltd. |

Market Trends

- Growing demand for durable, chemical-resistant materials and adhesive properties of paints and coatings fuels the growth.

- The technology advancements, with ongoing research and developments in formulation, drive the growth of the market.

- The industrial expansion and infrastructure development projects fuel the demand for the market.

- The emerging applications in electronics, renewable energy, and healthcare further fuel the growth of the market.

Market Opportunity

What Are the Key Growth Opportunities That Support the Growth of The Epoxy Resins Market?

The key growth opportunity that supports the growth of the market is the growing demand for biobased and eco-friendly alternatives, due to rising environmental concerns influences the growth of the market. The demand for biobased epoxy resins, which are derived from renewable resources, increases the adoption of the market. Bio-based epoxy resins offer a more sustainable alternative to traditional petroleum-based resins, with lower carbon emissions and reduced environmental impact. The technological advancements, like advancements in formulation with improved properties, drive the growth of the market.

Market Challenge

What Are The Key Challenges That Hinder The Growth Of The Epoxy Resins Market?

The market faces several challenges that hinder its growth of the market, like raw material price volatility, environmental and ethical concerns, regulatory challenges, supply chain disruption, technical limitations, market competition, workplace safety, and disposal of epoxy waste are some of the challenges that hinder the growth and expansion of the market.

Regional Insights

How Did Asia Pacific Dominate the Epoxy Resins Market In 2024?

Asia Pacific dominated the epoxy resins market in 2024. The growth of the market is driven by the growing industries in the region, like construction, automotive, electronics, renewable energy, and expanding manufacturing sectors contribute to the growth of the market. The strong and rapid industrialization, urbanization, and development of infrastructure across the region also support the growth of the market in the region. The increasing construction activity and availability of raw material in the region also increase the production expansion the market growth and expansion globally.

China Has Seen a Significant Growth in The Epoxy Resins Market

The growth of the market in China is driven by the growing construction industry and construction activities in the country, which increase the demand for epoxy resins, especially for coatings, adhesives, and structural applications in flooring, sealants, and composite materials. The government initiatives for promoting infrastructure development and economic growth, with heavy investment support the growth of the market.

The growing focus of the government on environmental regulations and policies also encourages the development and adoption of eco-friendly epoxy resins, fueling the growth of the market in the country.

North America Is Experiencing Growth Driven By The Rising Demand For The Material

North America is expected to witness rapid growth in the epoxy resins market in the forecast period. The growth of the market is driven by the rising demand for lightweight materials for vehicles for enhancing fuel efficiency and reducing emissions, driving the growth of the market in the region.

Technological advancements like innovation in epoxy resin technology, including bio-based and waterborne systems, also drive the adoption of sustainable construction practices in the region, driving the growth and expansion of the market in the region.

- The World shipped out 48,912 Epoxy Resin shipments from June 2024 to May 2025 (TTM). These exports made by 7,387 global Exporters to 8,528, showing a growth rate of 18% over the previous year.(Source : www.volza)

- Globally, China, South Korea, and the United States are the top three exporters of Epoxy Resin. China is the global leader in Epoxy Resin exports with 23,865 shipments, South Korea with 23,736 shipments, and the United States in 3rd place with 15,032 shipments.(Source: www.volza.com)

Segmental Insights

Physical Form Insights

Which Physical Form Segment Dominated The Epoxy Resins Market In 2024?

The liquid epoxy resins segment dominated the epoxy resins market in 2024. Liquid epoxy resins dominate the market due to their superior processing flexibility and broad applicability in coatings, adhesives, composites, and laminates. They offer excellent chemical resistance, mechanical strength, and adhesion properties, making them indispensable across construction, automotive, and electronics. In the market, liquid epoxies are increasingly adopted in high-performance coatings for industrial floors, marine structures, and wind turbine blades, supported by demand for durability and extended product life cycles.

The solid epoxy resins segment expects significant growth in the market during the forecast period. Solid epoxy resins are widely used in powder coatings, electrical laminates, and adhesives due to their strong thermal stability and hardness. They provide excellent corrosion resistance, making them suitable for automotive underbody coatings, pipeline linings, and appliance finishes. In the market, solid epoxy demand is expanding in the electronics sector, particularly in circuit boards and semiconductors. Growth is also fueled by eco-friendly, solvent-free applications emphasizing sustainability and performance.

Type Insights

How Did Bisphenol-A-Epoxy Segment Dominate The Epoxy Resins Market In 2024?

The bisphenol-A-epoxy resins segment dominated the epoxy resins market in 2024. Bisphenol-A-based epoxy resins are the most common type, offering exceptional mechanical strength, adhesion, and chemical resistance. In the market, these resins are extensively used in protective coatings, composites, and adhesives, particularly in aerospace, automotive, and infrastructure projects. Their versatility ensures wide adoption in both liquid and solid forms. Market growth is supported by advancements in high-performance formulations, though increasing regulatory scrutiny over BPA may encourage innovation in safer alternatives.

The novolac epoxy resins segment expects significant growth in the market during the forecast period. Novolac epoxy resins are specialty resins known for superior thermal stability, chemical resistance, and crosslinking density compared to Bisphenol-A resins. They are particularly valued in high-performance coatings, electrical laminates, and industrial adhesives, where durability under extreme conditions is critical. In the market, novolac resins are gaining traction in aerospace, oil and gas, and electronics sectors. Demand is supported by their suitability for harsh environments and applications requiring extended service life.

Raw Material Insights

Which Raw Material Segment Dominated The Epoxy Resins Market In 2024?

The bisphenol-A segment dominated the epoxy resins market in 2024. Bisphenol-A remains the leading raw material in epoxy resin production in the market, used predominantly in construction coatings, adhesives, and composites. It provides high transparency, strong adhesion, and excellent curing behavior, making it a go-to choice across multiple industries. BPA-based resins maintain strong demand due to cost-effectiveness and versatility. Market trends are encouraging innovation in low-VOC formulations and partially biobased alternatives.

The bisphenol-F segment is expected to experience significant growth in the market during the forecast period. Bisphenol-F is a key raw material offering lower viscosity and superior chemical resistance compared to Bisphenol-A. In the market, its use is expanding in coatings, adhesives, and composites that require enhanced mechanical properties and lower odor profiles. Bisphenol-F resins are particularly valued in wind turbine components, marine applications, and electronics, where performance under stress and resistance to aggressive chemicals are vital. Demand is further fueled by eco-friendly epoxy formulations.

Application Insights

How Did The Paints And Coatings Segment Dominate The Epoxy Resins Market In 2024?

The paints & coatings segment dominated the epoxy resins market in 2024. Paints and coatings represent one of the largest applications for epoxy resins in the market. Epoxy-based coatings provide outstanding adhesion, corrosion resistance, and durability, making them essential for infrastructure, marine, and industrial protective coatings. They are widely used in floor coatings, automotive refinishes, and pipeline linings. Rising construction projects, increased demand for protective industrial coatings, and the shift toward solvent-free, eco-friendly coatings continue to strengthen this application segment.

The wind energy components segment expects significant growth in the market during the forecast period. Epoxy resins are increasingly adopted in the US wind energy sector, particularly for manufacturing turbine blades, nacelles, and other composite components. Their excellent mechanical strength, fatigue resistance, and lightweight properties make them indispensable in enhancing turbine performance and lifespan. With the growing focus on renewable energy expansion, epoxy resin demand in this application is accelerating, supported by government incentives, sustainability targets, and advancements in composite manufacturing technologies.

End-Use Industry Insights

Which End-Use Industry Segment Dominated The Epoxy Resins Market In 2024?

The building & construction segment dominated the epoxy resins market in 2024. The building and construction sector is a major consumer of epoxy resins in the market, utilizing them in flooring systems, coatings, adhesives, and composites. Epoxies provide superior strength, abrasion resistance, and chemical durability, making them ideal for commercial and industrial infrastructure projects. Demand is supported by rapid urbanization, infrastructure upgrades, and the adoption of green building materials. This sector also benefits from epoxy’s role in sustainable and energy-efficient construction practices.

The renewable energy segment expects significant growth in the market during the forecast period. Renewable energy is a fast-growing end-use segment for epoxy resins in the market, with applications spanning wind turbines, solar panels, and energy storage systems. Epoxies enhance efficiency by offering lightweight strength, durability, and resistance to environmental stress. Government policies supporting renewable energy adoption and the rapid expansion of wind power capacity are key growth drivers. The trend toward sustainable, recyclable composites further supports epoxy resin demand in this sector.

Epoxy Resins Market Value Chain Analysis

Chemical Synthesis and Processing : The epoxy resins are synthesised and processed through mixing, curing, cross-linking, and modifying.

- Key players: Huntsman, Hexion, Dow, BASF, and Aditya Birla Chemicals

Quality Testing and Certification : The epoxy resins require ISO 9001, ISO 14000, and specific industry standards like MIL-STD 883/5011.

- Key players: Bureau of Indian Standards and Ministry of Commerce and Industry

Distribution to Industrial Users : The epoxy resins are distributed to the automotive, construction, electronics, and aerospace industries.

- Key players: DIC Corporation and Gantrade

Recent Developments

- In February 2025, Westlake Corporation announced the launch of EpoVIVE™, which is an epoxy product that offers a range of sustainable products which are developed with sustainability and focusing on environmental concerns due to rising concerns.(Source: www.businesswire.com)

Epoxy Resins Market Top Companies

- Hexion Inc.

- Olin Corporation

- Huntsman Corporation

- Nan Ya Plastics Corporation

- Kukdo Chemical Co., Ltd.

- Aditya Birla Chemicals

- Chang Chun Group

- Jiangsu Sanmu Group Co., Ltd.

- Sinopec Baling Company Limited

- Westlake Epoxy (Westlake Chemical Corporation)

- 3M Company

- Spolchemie

- Atul Ltd.

- NAGASE ChemteX Corporation

- LEUNA-Harze GmbH

- AnQore B.V.

- Emerald Performance Materials LLC

- DIC Corporation

- Mitsubishi Chemical Corporation

- Sumitomo Bakelite Co., Ltd.

Segments Covered

By Physical Form

- Solid Epoxy Resins

- Liquid Epoxy Resins

- Solution Epoxy Resins

By Type

- Bisphenol-A Epoxy Resins

- Bisphenol-F Epoxy Resins

- Novolac Epoxy Resins

- Aliphatic Epoxy Resins

- Glycidylamine Epoxy Resins

- Halogenated Epoxy Resins

- Others

By Raw Material

- Bisphenol-A

- Bisphenol-F

- Epichlorohydrin

- Phenols

- Others

By Application

- Paints & Coatings

- Adhesives

- Composites

- Electrical & Electronics

- Wind Energy Components

- Automotive Components

- Marine Applications

- Flooring & Construction Materials

- Packaging Materials

- Aerospace Components

- Others

By End-Use Industry

- Building & Construction

- Automotive

- Electrical & Electronics

- Aerospace & Defense

- Marine

- Renewable Energy (Wind, Solar)

- Industrial Equipment

- Consumer Goods

- Oil & Gas

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait