Content

What is the Current Advanced Materials Market Size and Share?

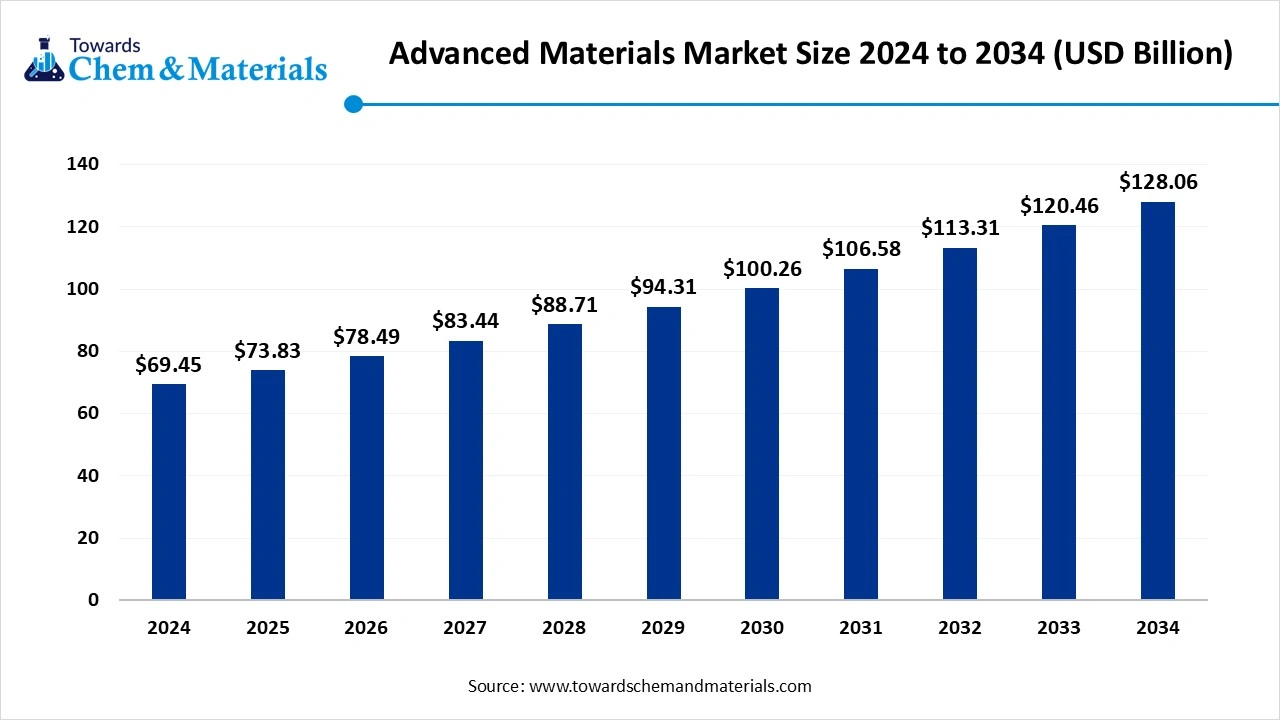

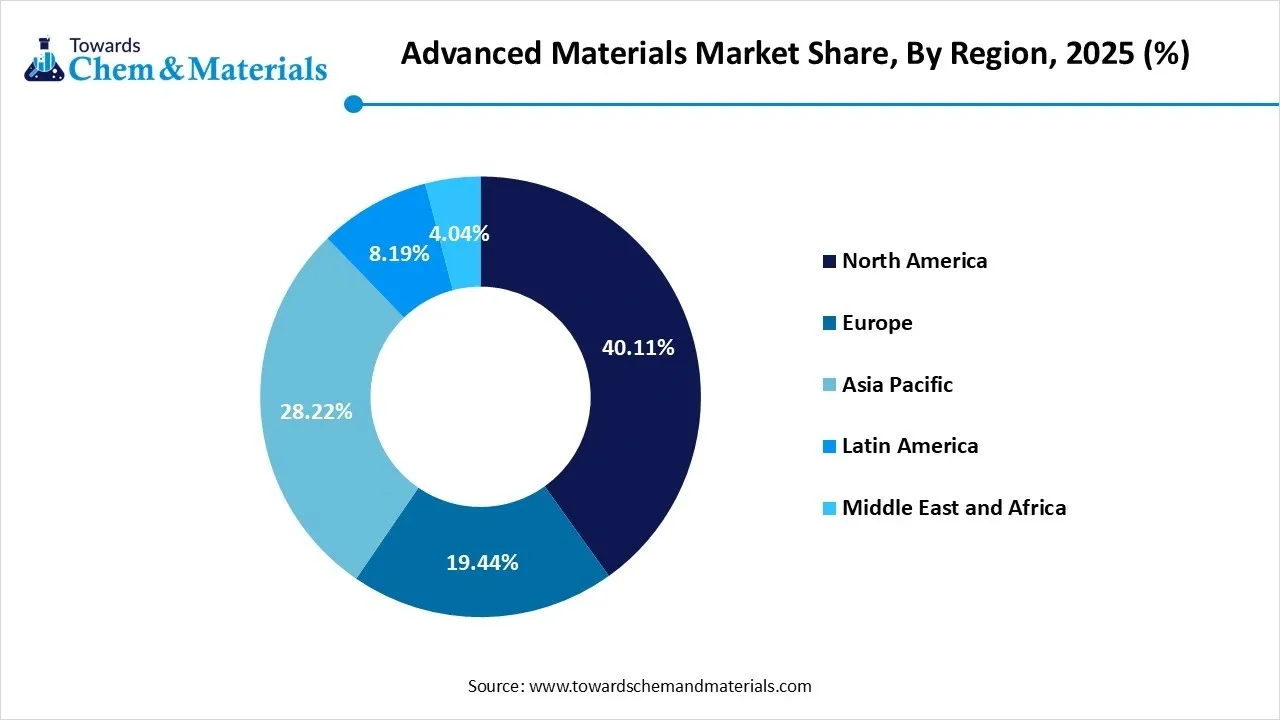

The global advanced materials market size was estimated at USD 87.55 billion in 2025 and is expected to increase from USD 162.35 billion in 2026 to USD 162.35 billion by 2035, growing at a CAGR of 6.37% from 2026 to 2035. North America dominated the advanced materials market with the largest share of 6.39% in 2025. The growing demand from various industries for advanced materials due to their properties and applications, like strength and lightweighting, drives the growth of the market.

Key Takeaways

- By region, North America led the advanced materials market held the share of around 6.39% in 2025.

- By region, Asia Pacific is expected to have significant growth in the market in the forecast period. The rising construction and automobile industry in the region, due to developing economies, drives the growth of the market in the region.

- By product type, the composites segment dominated the market in 2025. The growth of the segment is driven by the growing demand from various industries due to its lightweight property, which enhances functionality and performance.

- By product type, the polymer segment is expected to grow significantly in the market during the forecast period. It is also widely used in medical devices by providing durability, flexibility, and biocompatibility of the equipment and products, which drives growth.

- By application, the automotive segment dominated the market in 2025. The lightweight material demand from the automotive industry to improve the fuel efficiency of vehicles fuels the growth of the market.

- By application, the aerospace segment is expected to grow during the forecast period. Advanced materials play a key role in the aerospace industry as they demand lightweight, smart, strong, and durable materials

Market Overview

Rising Demand for Durable Materials: Advanced Materials Market to Expand

Advanced materials are the materials that are designed such that they possess novel properties and have novel and enhanced properties and are suitable for advanced applications. These materials have improved mechanical, chemical, and physical properties. They have properties like high strength, flexibility, durability, and conductivity, which make them suitable for application in various industries like automotive, medical devices, aerospace, electricals and electronics, industrial, and power. They are equipped unique properties that cater to specific applications, such as reducing weight, improving performance, increasing efficiency, and durability.

What are the Key Growth Drivers of the Advanced Materials Market?

The growth of the market is driven by the growing trends and shift towards industrialization, with increasing industrial activities with increasing demand for advanced materials in manufacturing and infrastructure. The rise in investment in research and development in nanotechnology and for enhancing the performance of the materials for development drives the growth of the market.

The growing demand from various industries for advanced materials like automotive, electronics, aerospace, and the healthcare sector for their durability, lightweight, high-strength, flexibility, along with focus and alignment with sustainability, drives the growth of the market. Key factor driving growth of the market is the advancement in technology enables innovation and development in various sectors, especially in the renewable energy sector requires advanced materials for efficient energy generation and storage, which further increases growth and expansion of the market.

Recent Trends in the Advanced Materials Market

- Electrification-Driven Materials Demand: Strong growth in lithium-ion batteries, electric drivetrains, and renewable energy systems is increasing demand for advanced cathode materials, thermal interface materials, lightweight aluminum alloys, and high-strength composites used in electric vehicles and grid-scale energy storage.

- Sustainability and Circular Material Design: Manufacturers are increasingly developing recyclable composites, bio-based polymers, and low-carbon cement and steel alternatives to comply with tightening environmental regulations and corporate sustainability targets, particularly in construction, automotive, and packaging applications.

- Acceleration of Additive Manufacturing Adoption: Advanced materials optimized for additive manufacturing, such as metal powders, high-performance polymers, and ceramic composites, are seeing higher adoption due to demand for rapid prototyping, lightweight part design, and complex geometries in aerospace, medical devices, and industrial tooling.

- Semiconductor and Electronics Material Expansion: Rising semiconductor fabrication capacity is driving demand for ultra-pure chemicals, specialty ceramics, advanced substrates, and thermal management materials used in chip packaging, power electronics, and data center infrastructure.

- Supply Chain Localization and Nearshoring: Geopolitical risk and supply disruptions are pushing manufacturers to localize production of critical advanced materials, including battery materials, specialty alloys, and electronic-grade inputs, closer to automotive and electronics manufacturing hubs.

Report Scope

| Report Attributes | Details |

| Market Size in 2026 | USD 93.13 Billion |

| Market Size by 2034 | USD 128.06 Billion |

| Growth Rate from 2025 to 2034 | CAGR 6.31% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| High Impact Region | North America |

| Segment Covered | By Product Type, By Application, By Region |

| Key Companies Profiled | 3M Company, Momentive Performance Materials Inc., BASF SE, DowDuPont Inc., Morgan Advanced Materials, Hanwha Group, PyroGenesis Canada Inc., Cytech Products Inc., Akzo Nobel N.V., Hexcel Corporation |

Value Chain Analysis

- Raw Material Sourcing & Processing: This involves the extraction and initial processing of basic materials, which are then refined or synthesized into specialized forms.

- Key Players: BASF SE, Dow, DuPont, Merck Group, Air Products, and Morgan Advanced Materials.

- Research & Development (R&D): This focuses on discovering new material properties, developing production processes, and designing materials with specific performance characteristics to meet market requirements.

- Key Players: 3M Company, Hexcel Corporation, and Momentive Performance Materials.

- Manufacturing & Synthesis: This involves the highly technical production of the advanced materials, often involving complex chemical synthesis, machining, packaging, and quality control processes.

- Key Players: Hexcel Corporation, Morgan Advanced Materials, PyroGenesis Canada Inc., and Cytech Products Inc.

- Distribution & Logistics: This includes activities ensuring the efficient transport and storage of products, from manufacturing sites to downstream.

- Key Players: DHL, FedEx, and UPS.

- Application & Integration and Service: This involves the application or integration of the advanced materials into end-user products to maintain and enhance product value.

- Key Players: Boeing, Airbus, Tesla, Toyota, Intel, and Samsung.

Market Opportunity

What is the Key Factor That Creates Opportunity for the Growth of the Market?

The growing demand from various industries creates an opportunity for the growth of the market. The rise in EV usage increases the demand for advanced materials due to their lightweight properties, high performance, and enhanced battery materials increases the growth. This use of advanced materials in energy storage and generation of renewable energy, in energy sector, the need for lightweight and strong materials in aerospace and defence, the use of advanced materials for signal transmission and heat management, and the use of advanced materials for industrial automation in manufacturing processes, and to increase efficiency. These factors and properties create an opportunity for the growth and expansion of the advanced materials market, aligning with sustainability and the environment.

Market Challenge

The Growing Cost, High Production Cost, and Limited Raw Material Availability

The advanced materials market faces a challenge in the growth of the market is the high cost of raw materials and also limited availability of materials like carbon fiber polymer. Advanced material production requires skilled labourers and high-quality raw materials for the formulation of the product, which adds to the final cost of the product this limiting the growth of the market. Additionally, lack of raw material availability results in fluctuation of prices, which affects the price-sensitive market, which affects the profitability of the final product; this is a challenge in the market.

Segmental Insights

Product Insights

How Did Composites Segment Dominate the Advanced Materials Market in 2024?

The composites segment dominated the advanced materials market in 2024. Composites are materials that are made with a combination of two or more constituents to have advanced properties, which are usually high-strength fibers with high stiffness, elasticity, temperature stability, and chemical resistance, which increases the demand. The growth of the segment is driven by the growing demand from various industries due to its lightweight property, which enhances functionality and performance.

The growing need for lightweight and high-strength composites in aircraft and military equipment fuels the growth. Used in the automotive industry to increase fuel efficiency and reduce weight, composites are widely used for their strength and resistance to environmental factors, driving demand from the construction industry for sustainable housing solutions. Technological advancement like nanotechnology and curing in composites manufacturing further significantly drives the market growth. These factors further help in the growth and expansion of the market.

The polymer segment is expected to experience significant growth in the advanced materials market during the forecast period. The advanced polymers are high-performance and engineering polymers that are specially designed with superior properties like resistance to heat, chemicals, and radiation, with strength and durability due to their applications in sectors that require the product to withstand extreme conditions and stress and demand performance like aerospace, defence, automotive, and biomedical industry. They are widely used in the medical sector to improve drug delivery and enhance the structural assembly of the drug and tissue engineering. It is also widely used in medical devices by providing durability, flexibility, and biocompatibility of the equipment and products. In the medical sector, advanced polymers are also used in nephrology, surgery, dentistry, oncology, and other specialties due to their functions and applications. These applications and properties further boost the growth and expansion of the market.

Application Insights

What Made the Automotive Segment Dominate the Advanced Materials Market in 2024?

The automotive segment dominated the advanced materials market in 2024. The growing automotive sector in regions demands high-performance and advanced materials, which play a crucial role in improving strength, fuel efficiency, and vehicle performance. The lightweight material demand from the automotive industry to improve the fuel efficiency of vehicles fuels the growth of the market. Advanced material enhances safety by providing a stronger vehicle structure, lightweight materials improve performance, handling, and acceleration of the vehicle. The rising EV adoption demands advanced materials for its manufacturing, for flexible design, innovation, and more aerodynamic vehicles, Also, the product aligns with the environment and contributes to a more sustainable automotive industry, which further boosts the growth of the market and supports expansion of the market.

The aerospace segment is expected to experience significant growth in the advanced materials market during the forecast period. Advanced materials play a key role in the aerospace industry as they demand lightweight, smart, strong, and durable materials for building aircraft and other components to enhance the performance of the product. Light aircraft and spacecraft contribute to a reduction in fuel consumption and lower emissions, which contributes to sustainability amid rising environmental concerns. Cost reduction due to enhanced durability and reduced weight leads to lower maintenance costs, which supports the consumers, which fuels the growth of the market. Advanced materials also contribute to enhancing the structural integrity and improving the safety and shelf life of aircraft and spacecraft. These factors support the growth and expansion of the market.

Regional Insights

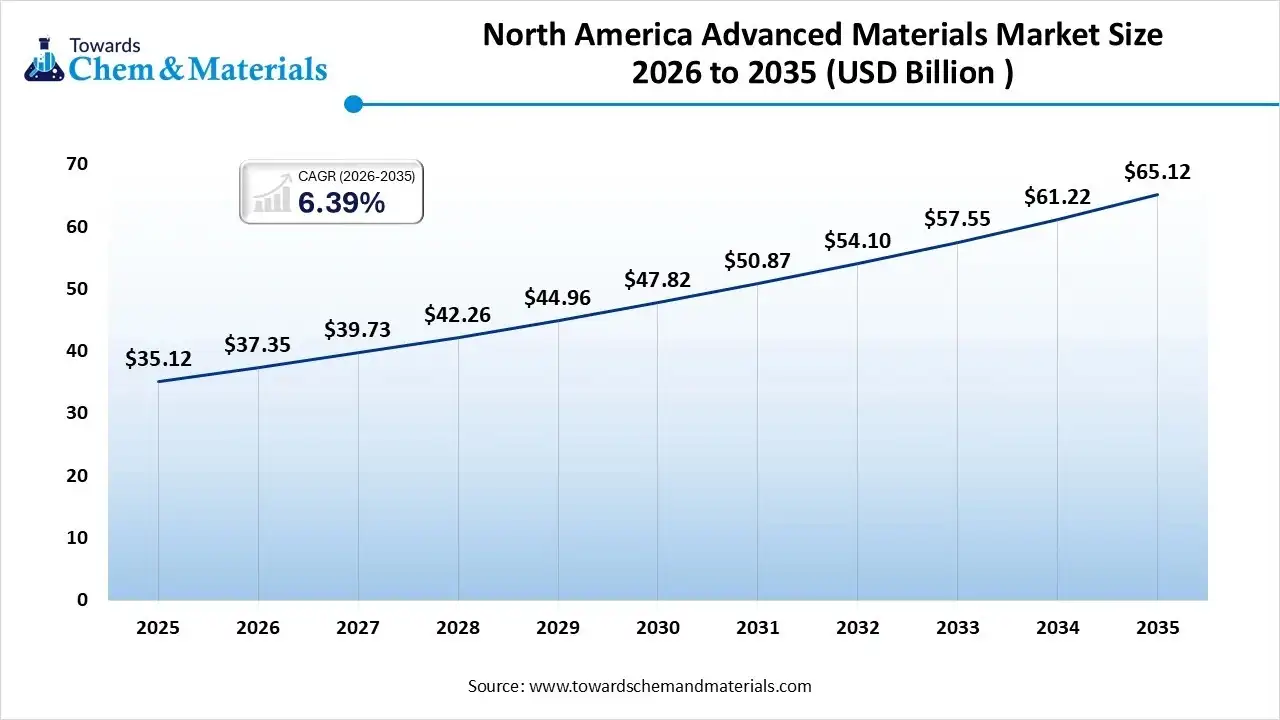

The North America advanced materials market size was valued at USD 35.12 billion in 2025 and is expected to be worth around USD 65.12 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 6.39% over the forecast period from 2026 to 2035.

North America dominated the advanced materials market in 2024. The robust industrial expansion and growth in the region drive the demand for advanced materials due to their properties like high performance, durability, flexibility, efficiency, lightweighting, and strong materials. High strength drives the growth of the market in the region. The growing investment in research and development by government and private organizations in every sector, especially in medical devices and implants, with the rising demand for devices with the rising prevalence of diseases and conditions, fuels the growth of the market in the region. The driving demand for lightweight materials from the aerospace and automotive industries is to enhance the performance and efficiency of the product, and strong advanced manufacturing processes and sectors in the region further fuel the growth and expansion of the market in the region.

Why has Europe Emerged as a hub for the Advanced Materials Market?

Europe is recognized as a rapidly growing region, driven by its strong industrial base, sustained investment in research and development, and a clear strategic focus on sustainability and circular economy practices. The region’s manufacturing ecosystem places high value on material efficiency, regulatory compliance, and lifecycle performance, which supports steady demand for advanced and specialty materials across multiple industries.

Well-established sectors such as automotive, aerospace, electronics, and construction form the backbone of this demand, particularly as these industries transition toward lightweighting, electrification, low-emission production, and high-performance components. Countries including Germany, France, and the United Kingdom lead the region’s industrial output and innovation activity, supported by dense supplier networks and strong collaboration between industry and research institutions.

Germany Advanced Materials Market Trends

Germany is a major contributor to the global market, focusing on high-performance materials for its established automotive, aerospace, and engineering sectors. The country is also a pivotal player in the European semiconductor industry, developing specialized materials for applications in automotive technology, industrial automation, and 5G networks, along with a strong emphasis on creating eco-friendly materials, recycling solutions, and materials for renewable energy applications.

What factors are pushing Latin America to experience a Surge in the Advanced Materials Market?

Latin America is becoming increasingly significant in the global market, supported by its abundant reserves of critical minerals, a strategic geographic position that enables nearshoring, and the steady expansion of manufacturing and digital services ecosystems. Proximity to North American and European markets is encouraging multinational companies to diversify supply chains and relocate production closer to end markets, strengthening regional industrial relevance.

The region is gradually transitioning from a traditional role as a raw material supplier toward an integrated hub for higher-value manufacturing and industrial processing. This shift is underpinned by growing investment in downstream capabilities, industrial clusters, and infrastructure that support value-added production rather than commodity exports alone.

Rising demand for high-performance and advanced materials across automotive, aerospace, electronics, and construction industries is a key driver of this transition. Countries such as Brazil and Mexico are at the forefront, benefiting from established industrial bases, skilled labor pools, and strong integration into global manufacturing supply chains.

Brazil Advanced Materials Market Trends

Brazil is playing an evolving role in the global market, characterized by its rich natural resources, growing manufacturing base, and an increasing focus on sustainable, bio-based materials. The country has substantial reserves of critical minerals such as graphite, rare earth elements, copper, nickel, and lithium, positioning it as a strategic supplier of raw materials. Brazil is actively working to reduce its dependence on imported high-tech materials, such as semiconductor components, by promoting local R&D and attracting foreign investment to develop domestic production capabilities.

How will the Middle East and Africa contribute to the Advanced Materials Market?

The Middle East and Africa region is emerging as an increasingly important contributor to the advanced materials market, driven by large-scale government-led infrastructure development, long-term economic diversification strategies, and a growing focus on sustainability and technological innovation. National development plans across the region are prioritizing advanced manufacturing, smart infrastructure, and high-value industrial capabilities to reduce dependence on hydrocarbons and traditional commodity exports.

The region is witnessing a surge in futuristic urban and industrial megaprojects, particularly across the Gulf Cooperation Council countries. Smart cities, high-performance transportation networks, renewable energy infrastructure, and digitally enabled buildings are creating strong demand for advanced construction materials, lightweight composites, specialty coatings, and high-durability materials that meet strict performance and sustainability criteria.

Middle East and Africa possess substantial mineral and raw material resources that can support localized production of advanced materials. Availability of high-purity minerals and strategic investments in downstream processing are enabling the development of materials used in electronics, energy storage, and semiconductor-adjacent applications. Governments are increasingly encouraging local value addition through industrial zones, incentives for advanced manufacturing, and partnerships with global technology providers.

UAE Advanced Materials Market Trends

The United Arab Emirates is emerging as a key player in the global market, driven by the rapid adoption of smart city projects, 5G networks, and the expansion of data centers. These developments are increasing the demand for advanced electronic materials and semiconductor components that can operate in high temperatures. There is also a growing focus on integrating sustainability into industrial production, including the use of renewable energy in manufacturing processes and initiatives promoting a circular economy for industrial waste.

Recent Developments

- In December 2025, researchers at the University of Chicago reported the development of a new computational approach that builds on a framework called Localized Active Space (LAS) by extending it to periodic solids. The team in Chicago created a hybrid method that merges local quantum chemistry with global band theory with applications in a variety of disciplines ranging from high-temperature superconductors to solar cell semiconductors.(Source: phys.org)

- In May 2025, researchers from the National University of Singapore developed a 3D printed self-powered auxetic ML photonic skin. Deliberately selecting for auxetic materials with a negative Poisson’s ratio, the scientists were able to create a stretchable ML device that conforms to complex, curved surfaces, enhancing its applicability in dynamic underwater settings. The device exhibited significantly increased durability, maintained consistent light emissions and delivered a superior mechanical performance over 10,000 cycles.(Source: advanced.onlinelibrary.wiley.com )

Top Companies List

- 3M Company

- Momentive Performance Materials Inc.

- BASF SE

- DowDuPont Inc.

- Morgan Advanced Materials

- Hanwha Group

- PyroGenesis Canada Inc.

- Cytech Products Inc.

- Akzo Nobel N.V.

- Hexcel Corporation

Segments Covered in the Report

By Product Type

- Polymers

- Metal & Alloys

- Glasses

- Composites

- Ceramics

By Application

- Medical Devices

- Automotive

- Aerospace

- Electricals & Electronics

- Industrial

- Power

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait