Content

Plastic Adhesives Market Size and Growth 2025 to 2034

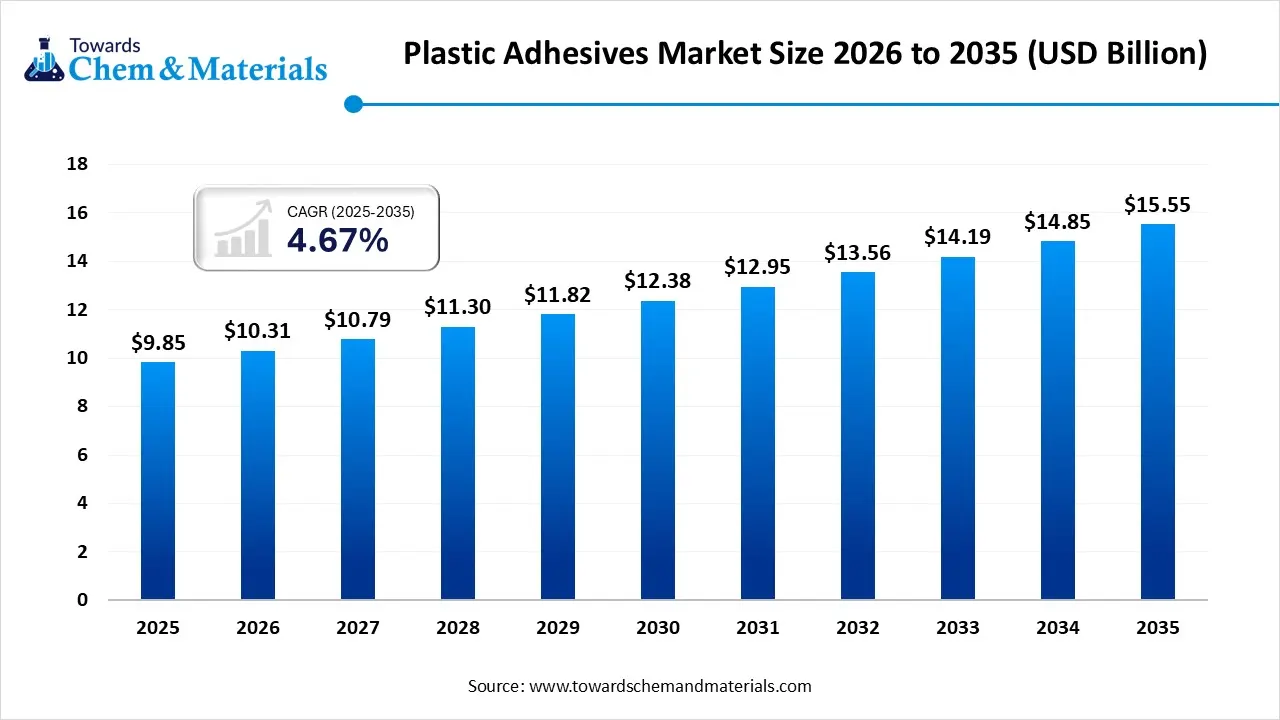

The global plastic adhesives market size was estimated at USD 9.85 billion in 2025 and is expected to increase from USD 15.55 billion in 2026 to USD 15.55 billion by 2035, growing at a CAGR of 4.67% from 2026 to 2035. The expansion of healthcare infrastructure, assembly of flexible displays, and need for strong bonding solutions with lightweight in the construction sector is poised to stimulate industry expansion in the future.

Plastic Adhesives Market Key Takeaways

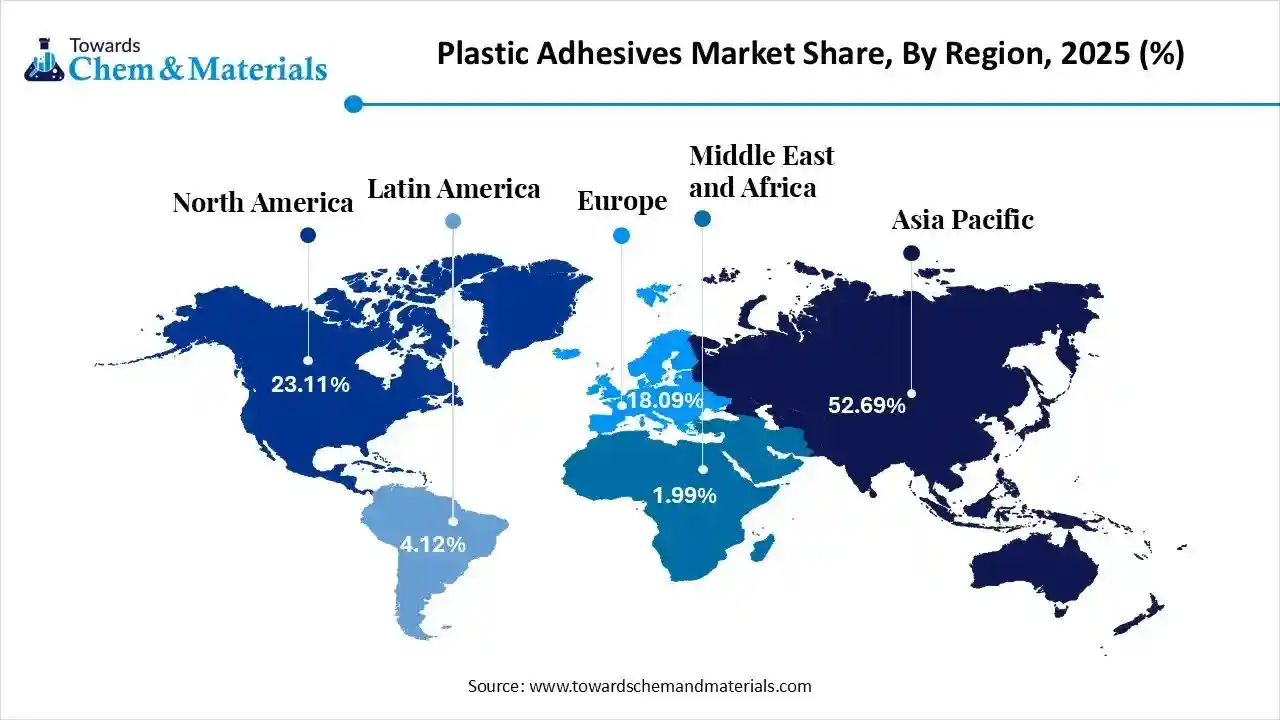

- Asia Pacific dominated the plastic adhesives market in 2025

- North America is anticipated to grow significantly in the market during the forecast period.

- By resin type, the polyurethane segment held the dominating share of the market in 2025.

- By resin type, the epoxy segment is expected to experience significant market growth during the forecast period.

- By substrate, the Polyethylene (PE) segment dominated the cement paints industry with a revenue share of 35.19%.in 2025, and is projected to grow through 2034.

- By application type, the automotive segment led the plastic adhesives market in 2025.

- By application type, the packaging segment expects significant growth in the market during the forecast period.

- By curing method, the solvent-based segment held the largest share of the market in 2025.

- By curing method, the water-based segment is expected to grow at the fastest rate in the market during the forecast period.

Plastic Adhesives Market Overview

The plastic adhesives market has experienced fast-paced growth in the recent period. The worldwide demand for high-performance bonding solutions for multiple industry applications has contributed to market expansion nowadays. Affordability and durability are often leading plastic adhesive sales in recent days. Individuals are actively using plastic adhesives methods, which is more efficient and cost-effective as compared to traditional methods like mechanical fasteners and welding nowadays. According to these properties of plastic adhesives, the market can maintain its dominance in the future.

The need for modern and advanced medical devices is expected to drive sector growth in the coming period. With the sudden surge in the prevalence of diseases and the development of healthcare infrastructure, plastic adhesives are expected to play a major role in the manufacturing of healthcare devices in the future. Plastic adhesives are used widely in the making of healthcare devices such as wearable healthcare monitors, syringes, catheters, and surgical instruments nowadays. Also, by providing resistance to sterilization, higher strength, flexibility, and biocompatibility to the miniaturization of medical devices, plastic adhesives can have a substantial market share during the forecast period. Also, the automotive industry will become a crucial consumer of plastic adhesives in the future.

Recent Trends in the Plastic Adhesives Market

- Rising Demand From Lightweight and Multi-Material Bonding: Increasing use of lightweight plastics and composite materials in automotive, aerospace, and electronics manufacturing is driving demand for plastic adhesives that replace mechanical fasteners and enable durable multi-material bonding.

- Growth in Packaging and Consumer Goods Applications: Expansion of flexible packaging, medical packaging, and consumer products is increasing adoption of plastic adhesives that offer fast curing, transparency, and strong adhesion across polyethylene, polypropylene, PET, and engineered plastics.

- Shift Toward High-Performance and Specialty Adhesives: Industries are increasingly using structural acrylics, polyurethane, and epoxy-based plastic adhesives to meet higher requirements for impact resistance, chemical stability, and long-term durability.

- Sustainability and Low-VOC Formulation Trends: Regulatory pressure and brand sustainability goals are accelerating development of solvent-free, low-VOC, and recyclable-compatible adhesive formulations suitable for plastic substrates.

- Advances in Adhesive Chemistry and Application Technologies: Innovation in surface activation, primer-less bonding, and fast-setting adhesive systems is improving bond strength, processing speed, and automation compatibility in high-volume manufacturing environments.

Plastic Adhesives Market Report Scope

| Report Metric | Details |

| Market Size in 2026 | USD 10.31 Billion |

| Expected Market Size in 2035 | USD 15.55 Billion |

| Growth Rate | CAGR of 4.67% |

| Base Year of Estimation | 2025 |

| Forecast Period | 2026-2035 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Resin Type,Substrate,Application,Curing Method,Region |

| Key Companies Profile | 3M,Arkema,Ashland Inc,Dow Inc, Dymax Corporation, H.B. Fuller, Henkel AG, Illinois Tool Works, Mapei S.P.A., Master Bond Inc |

Value Chain Analysis

- Raw Material Acquisition and Chemical Production: This involves sourcing basic feedstocks, which are refined through processes to produce primary chemical building blocks and then converted into monomers and polymers.

- Key Players: BASF SE, Dow Inc., Huntsman International LLC, and Arkema SA.

- Adhesives Manufacturing and Formulation: In this, polymers and resins are combined with various additives to create a final adhesive.

- Key Players: Henkel AG, 3M Company, H.B. Fuller Company, Sika AG, Mapei SpA, and Pidilite Industries.

- Sales, Marketing, and Distribution: In this, finished adhesive products are distributed globally through various channels to reach end-use manufacturers.

- Key Players: DHL Group, FedEx Logistics, and Quimidroga.

- Application and Assembly: This involves the application of adhesives within various manufacturing processes to bond plastic to plastic or other substrates like metal, wood, and ceramic.

- Key Players: Ford, Toyota, Amcor, and Siemens Healthineers.

Market Dynamics

Market Drivers

The plastic adhesives market is driven by increasing demand for lightweight and durable bonding solutions across automotive, aerospace, electronics, medical devices, and packaging industries. Manufacturers are replacing mechanical fasteners with adhesives to enable multi-material bonding, reduce component weight, and improve structural integrity. Rapid growth in flexible packaging, medical packaging, and consumer goods is further increasing demand for fast-curing, high-clarity, and food-safe plastic adhesives. Rising automation in manufacturing lines are also favoring adhesive systems compatible with high-speed dispensing and curing processes.

Market Restraints

Performance limitations when bonding low-surface-energy plastics such as polyethylene and polypropylene remain a key restraint, often requiring surface treatment or primers that increase process complexity. Volatility in raw material prices for resins, solvents, and additives can impact cost stability for manufacturers and end users. Strict regulations on volatile organic compounds (VOCs) and hazardous substances are increasing compliance costs and reformulation requirements. In addition, long curing times or sensitivity to temperature and humidity can limit adhesive use in certain high-throughput or outdoor applications.

Market Opportunities

Strong opportunities are emerging from the shift toward electric vehicles, renewable energy systems, and advanced electronics, all of which rely heavily on plastic and composite components. Development of low-VOC, solvent-free, and recyclable-compatible adhesives aligns with sustainability goals across industries. Innovations in primerless bonding, surface activation technologies, and bio-based adhesive chemistries are expanding application scope. Growth in medical devices and wearable electronics is also creating demand for skin-safe, flexible, and high-performance plastic adhesives.

Market Challenges

Achieving consistent bond strength across diverse plastic substrates and operating conditions remains a technical challenge. Adhesive durability under thermal cycling, chemical exposure, and mechanical stress requires continuous formulation improvement. Integrating adhesives into automated production lines without compromising speed or quality can be complex. Additionally, balancing sustainability requirements with high performance and cost competitiveness is increasing R&D intensity and time-to-market pressures for adhesive manufacturers.

Segmental Insights

By Resin Type

The polyurethane segment held the dominating share of the plastic adhesives market in 2025. Having demand from various industries such as construction, packaging, and automotive due to wide application with providing durability and strong bonding properties, the polyurethane segment gained significant market attention in recent years. Moreover, its suitability for various surfaces such as metals, wood, and rubber are continuously contributing to the sale of the polyurethane segment nowadays. Furthermore, the polyurethane adhesives can maintain bonding in harsh environments, and this makes it a key solution for the applications requiring high durability.

The epoxy segment is expected to experience significant market growth during the predicted period. The expansion of the construction industry can lead to the epoxy segment growth during the forecast period as epoxy becomes an ideal solution for the structural bond by having the ability to withstand extreme temperatures and high pressure. Also, the epoxy segment has higher resistances in water and heat application, which can help epoxy’s to gain market attraction in the future.

By Application Type

The automotive segment led the plastic adhesives market in 2025. The tragic shift towards fuel efficiency and lightweight vehicles has heavily contributed to automotive segment growth in recent years. automotive manufacturers are increasingly using plastic adhesives in their vehicles while replacing the traditional alternatives such as welds, screws, and bolts which are heavier than adhesives. Also, plastic adhesives were seen in maintaining structural integrity in material bonding.

The packaging segment is expected to grow at the fastest rate during the forecast period. increasing need for durable plastics, efficient packaging solution can lead the segment growth during the forecast period. The sudden surge in demand for packaging materials that can ensure product safety is expected to gain a consumer base for plastic adhesives in the packaging industry in the future. The manufacturers are currently seeking products that can have superior sealing, durability, and tamper resistance in the packaging industry.

By Curing Method

The solvent-based segment held the largest share of the market in 2025. By having superior qualities and faster drying times, solvent-based adhesives have gained market potential in recent years. These adhesives contain solvents that can evaporate quickly, providing instant bonding solutions. As a result, several industries are using these adhesives for the production process and to reduce downtime in the current period.

However, the water-based segment is expected to grow at the fastest rate in the market during the forecast period. Rising eco-friendly initiatives globally for bonding solutions can lead to segment growth during the forecast period, as the water-based solvent contains a lower amount of harmful chemicals than the solvent-based adhesives, which increases acceptance of the water-based solving in modern industry nowadays.

Regional Insights

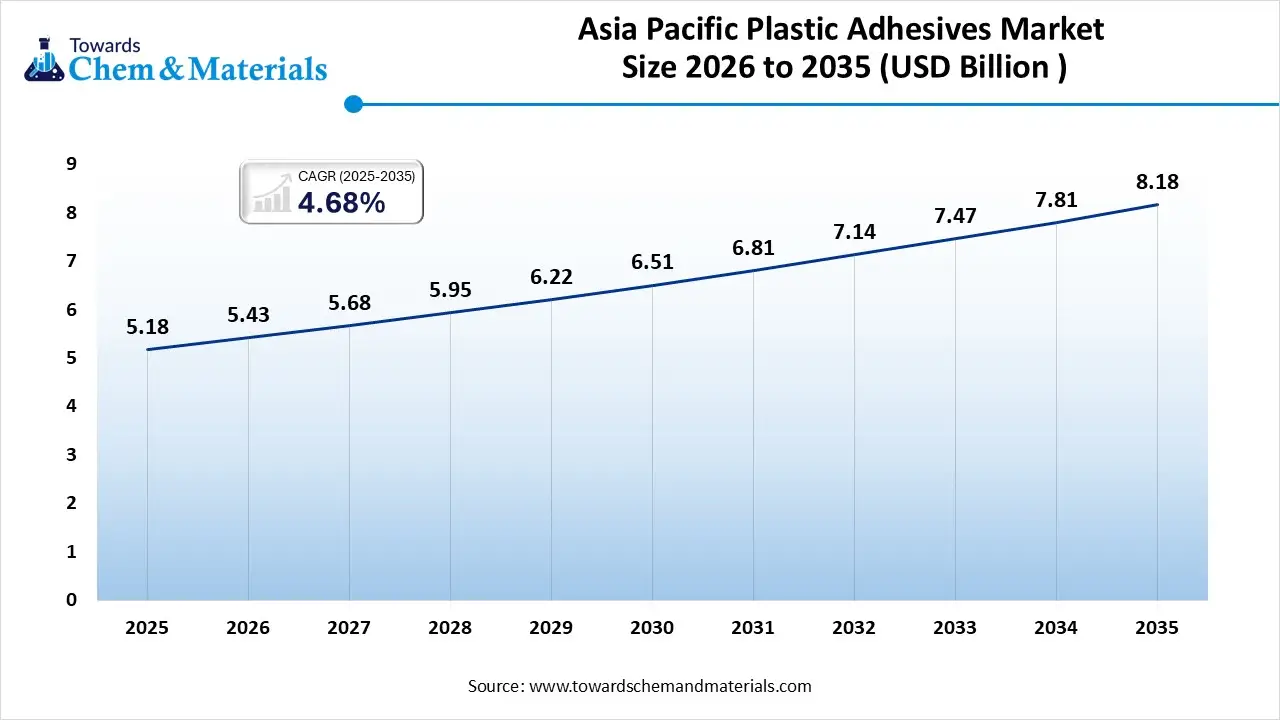

The Asia Pacific plastic adhesives market size was valued at USD 5.18 billion in 2025 and is expected to be worth around USD 8.18 billion by 2035, exhibiting at a compound annual growth rate (CAGR) of 4.68% over the forecast period from 2026 to 2035.

The rapid industrialization, higher plastic consumption rate, and heavy manufacturing industry presence are continuously contributing to the region's growth over the period. The enlarged packaging industry gained major market share in the past period from the region. The significant e-commerce boom and growing middle-class population are the main reasons behind the industry's growth during this period.

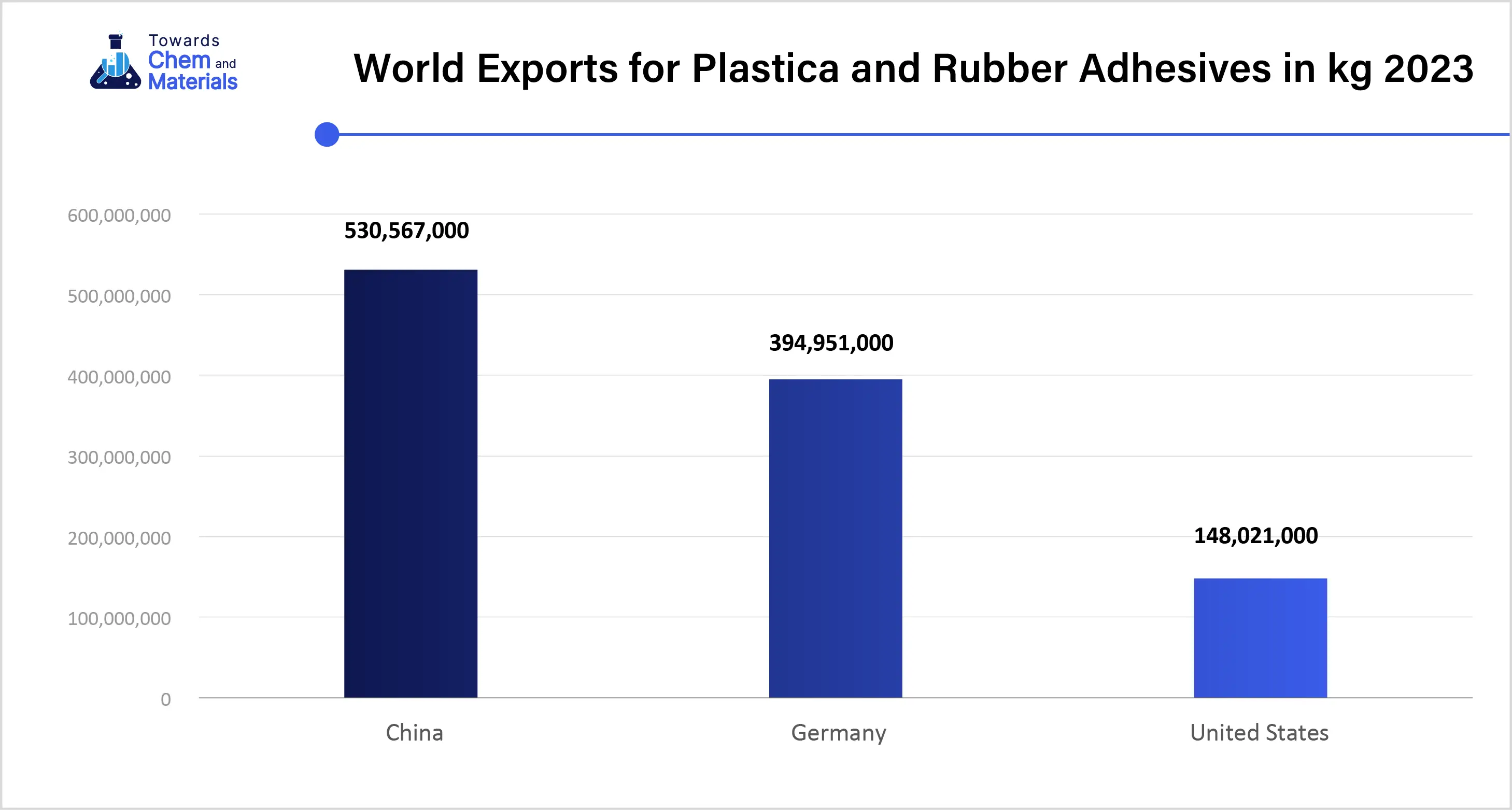

China’s Plastic Adhesives Market Thrives on Low Costs & Tech Growth.The heavy production of plastics is leading to China's dominating reputation in the global plastic adhesives market. Moreover, advantages such as low labor costs and a skilled workforce are severely contributing to the country’s growth in the plastic adhesives market. The increasing popularity of plastic containers and packaging solutions due to the low-cost initiatives is expected to lead the future growth of the plastic industry in the coming years. Also, the remarkable technology growth in the consumer electronics industry has gained market attraction in recent days in China.

Why did Europe consider a Notable Region in the Plastic Adhesives Market?

Europe is anticipated to experience significant growth in the near future, largely driven by the rising demand for sustainable, high-performance bonding solutions across key industries such as automotive, packaging, and construction. This growth is primarily influenced by strict environmental regulations and advancements in technology. Regulations from the European Union, such as the Registration, Evaluation, Authorisation, and Restriction of Chemicals, as well as initiatives promoting a circular economy, encourage manufacturers to develop safer formulations, including low-VOC, water-based, and solvent-free options.

Germany Plastic Adhesives Market Trends

Germany plays a crucial role in this market, recognized for its emphasis on innovation and sustainable solutions. As a hub for technology and innovation, Germany significantly influences global trends in adhesive development and applications in sectors like construction, electronics, and medical device manufacturing. The strong automotive industry in Germany drives substantial demand for improvements in fuel efficiency and structural integrity, leading to a shift away from traditional mechanical methods.

Emergence of Latin America in the Plastic Adhesives Market

Latin America is also a significant contributor to the global market, primarily fueled by a rapid surge in construction and infrastructure projects, particularly in Brazil and Argentina. The expansion of automotive manufacturing in the region is another key driver for the demand for plastic adhesives. Continuous industrial development and rapid urbanization across Latin America, especially in Mexico and Brazil, further boost the need for adhesives in various applications, including consumer goods, furniture, and electronics manufacturing, through the introduction of advanced product lines.

Brazil Plastic Adhesives Market Trends

Brazil is a significant and growing market within Latin America, characterized by strong domestic demand in key sectors and a move toward eco-friendly solutions. The market is primarily driven by the expanding construction and automotive industries, along with a booming e-commerce sector that increases demand for packaging adhesives and local regulations like ANVISA and global sustainability trends.

How will the Middle East and Africa Surge in the Plastic Adhesives Market?

The Middle East and Africa represent another important region in the global market, driven by rapid industrialization, large-scale construction projects, and the growth of industries such as packaging and automotive. Countries like South Africa, the UAE, and Morocco are investing in their domestic automotive sectors while attracting global players. Regional governments actively promote industrial growth, economic diversification, and sustainable practices through various initiatives, tax incentives, and the establishment of economic zones.

UAE Plastic Adhesives Market Trends

The UAE stands out as a regional hub due to its extensive infrastructure and construction projects, alongside efforts for economic diversification and sustainability. Major urban development projects in cities like Dubai and Abu Dhabi create significant demand for adhesives, particularly in structural applications, flooring, and façade work, which must endure harsh environmental conditions.

North America expects significant growth in the market during the forecast period. The modern and advanced industrial infrastructure and heavy need from the end-use consumers can lead to market progress in the next decade. Furthermore, the region's enlarged automotive industry is consuming large amounts of plastic adhesives in the current period, aiming to improve fuel efficiency and comply with emission regulations. These automakers are increasingly replacing traditional adhesives, which are heavy and time-consuming, with plastic adhesives that are lightweight, durable, and suitable for high temperatures in the region.

The presence of high-tech industries is anticipated to contribute to the country's growth in the United States in the future. These high-tech industry manufacturers are seen in demanding plastic adhesives for various purposes such as display manufacturing, chip bonding, and microelectronic packaging these days. Moreover, the advanced medical industry, which is globally appreciated, is also using plastic adhesive in the manufacturing of healthcare devices due to the properties of plastic adhesives, such as flexibility and biocompatibility in the United States. The market for plastic adhesives looks promising during the forecast period.

Recent Developments

- In December 2025, RecyClass, an initiative to bring transparency to the origin of plastic waste, released an updated version of its Recyclability Evaluation Protocol for Labels & Adhesives applied on PET bottles. This follows work carried out by the RecyClass PET Technical Committee that brought together experts from across the packaging value chain, including label and adhesive manufacturers, recyclers, and converters.(Source: www.iom3.org)

- In December 2025, Henkel Adhesive Technologies joined the Global Impact Coalition (GIC), a CEO-led initiative to help the chemical industry transition to net-zero.(Source: www.plasticsnews.com)

Plastic Adhesives Market Top Companies List

- 3M

- Arkema

- Ashland Inc

- Dow Inc

- Dymax Corporation

- H.B. Fuller

- Henkel AG

- Illinois Tool Works

- Mapei S.P.A.

- Master Bond Inc

Segments Covered In The Report

By Resin Type

- Acrylic

- Silicone

- Others

- Polyurethane

- Epoxy

By Substrate

- Polyethylene (PE)

- Polypropylene (PP)

- PVC

- Other

By Application

- Automotive

- Building and Construction

- Electrical and Electronics

- Packaging

- Transportation

- Medical Devices

- Consumer Goods

- Other

By Curing Method

- Solvent-Based

- Water-Based

- Heat-Activated

- UV-Cured

By Regional

- North America

- U.S.

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- Japan

- China

- India

- Australia

- South Korea

- Thailand

- Latin America

- Brazil

- Argentina

- The Middle East and Africa

- South Africa

- Saudi Arabia

- UAE

- Kuwait