Content

What is the U.S. Steel Rebar Market Size?

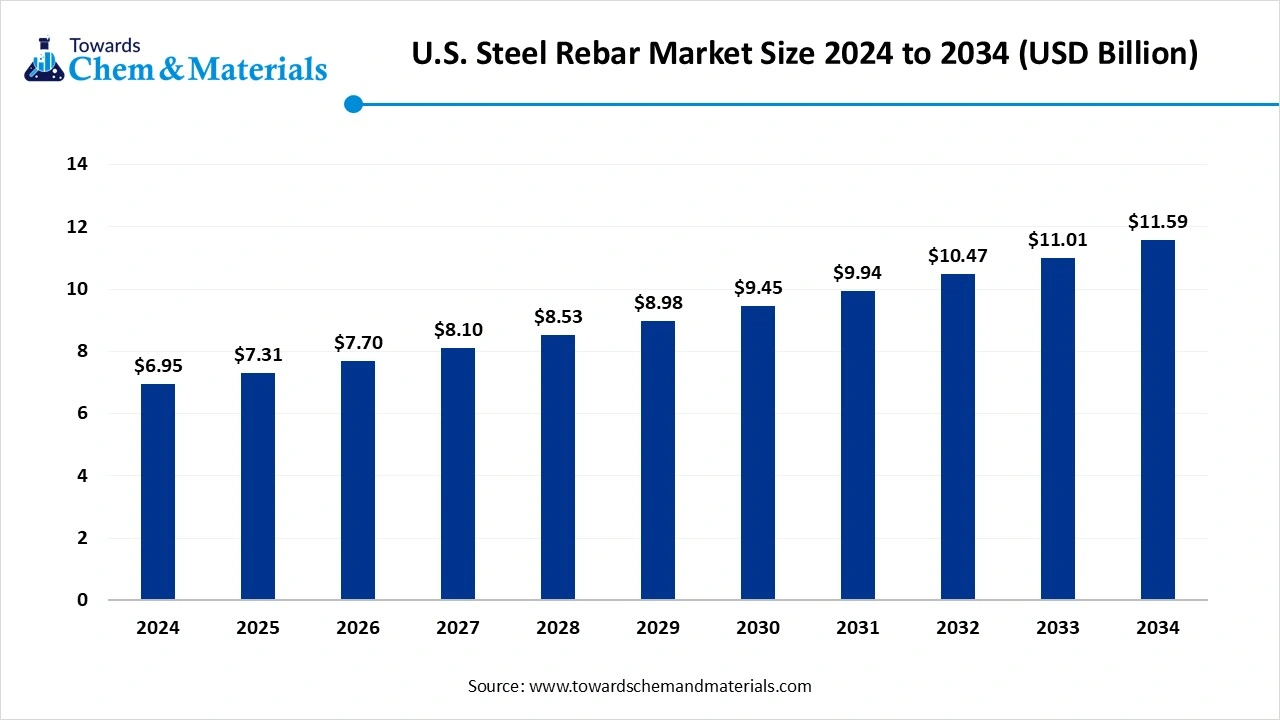

The U.S. steel rebar market size was estimated at USD 7.31 billion in 2025 and is predicted to increase from USD 7.70 billion in 2026 to approximately USD 11.59 billion by 2034, expanding at a CAGR of 5.25% from 2025 to 2034. The growing development of infrastructure projects and stringent building codes drive the market growth.

Key Takeaways

- By product type, the deformed steel rebar segment held a 70.65% share in the market in 2024.

- By product type, the mild steel rebar segment is expected to grow at the fastest CAGR in the market during the forecast period.

- By coating type, the plain carbon steel segment held a 50% share in the market in 2024.

- By coating type, the epoxy coated segment is expected to grow at the fastest CAGR in the market during the forecast period.

- By process type, the basic oxygen furnace segment held a 69.28% share in the market in 2024.

- By process type, the electric arc furnace segment is expected to grow at the fastest CAGR in the market during the forecast period.

- By application, the infrastructure segment held a 67.3% share in the U.S. steel rebar market in 2024.

- By application, the residential buildings segment is expected to grow at the fastest CAGR in the market during the forecast period.

- By distribution channel, the direct sales segment held a 60% share in the market in 2024.

- By distribution channel, the distributors segment is expected to grow at the fastest CAGR in the market during the forecast period.

What is U.S. Steel Rebar?

The U.S. steel rebar market growth is driven by growing commercial & residential construction activities, increasing investment in infrastructure development, high demand for durable construction material, and strong government support for construction activities.

Steel rebar (steel reinforcement bar) is a reinforcing bar used in concrete structures to offer tensile strength to concrete structures. They help to minimize slippage, maintain structural integrity, and offer superior bonds in construction projects. They prevent issues like failing & cracking in concrete. Steel rebar is used as steel mesh and individual bars. Steel rebar enhances the longevity of concrete structures and increases structural strength.

Report Scope

| Report Attributes | Details |

| Market Size in 2026 | USD 7.70 Billion |

| Expected Size by 2034 | USD 11.59 Billion |

| Growth Rate from 2025 to 2034 | CAGR 5.25% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Segment Covered | By Product Type, By Coating Type, By Process Type, By Application, By Distribution Channel |

| Key Companies Profiled | ArcelorMittal (U.S. operations), EVRAZ North America, JSW Steel USA, NLMK USA, Liberty Steel USA, Cascade Rolling Mills, Inc., Alton Steel (Gerdau/Alton facilities), Schnitzer Steel Industries, Inc., Vinton Steel, LLC, Adelphia Metals, Bushwick Metals (and related fabricators), Halton Rebar (regional fabricator), Insteel Industries, Inc., Hybar LLC, Leeco Steel, LLC |

U.S. Steel Rebar Market Outlook:

- Industry Growth Overview: Between 2025 and 2034, the industry is expected to see accelerated growth in high-margin niches such as commercial construction, infrastructure development, and residential construction. Growth is being reinforced by high investment in infrastructure projects and expansion of construction activities in states like California, Illinois, and Texas.

- Sustainability Trends: Sustainability is reshaping the U.S. steel rebar industrial landscape, with rising demand for green steel products, use of recycled content, and adoption of the electric arc furnace. For instance, Nucor uses EAF technology for the production of steel and utilizes 75% recycled content in steel products.

- Major Investors: Private equity and foreign companies are actively investing in the space, drawn by a strong focus on sustainable production and development of infrastructure. Companies like Commercial Metals Company, Gerdau, Nucor Corporation, ArcelorMitttal USA, and Nucor Corporation are heavily investing in steel rebar producti

Key Technological Shifts in the U.S. Steel Rebar Market:

The U.S. steel rebar market is undergoing key technological transformations driven by the demand for sustainability, improving efficiency, and enhancing quality. One of the most significant shifts is the integration of Artificial Intelligence (AI), enabling energy optimization and minimizing unplanned downtime. AI helps in analyzing micro defects like impurities, cracks, & surface irregularities in steel rebar and optimizes the manufacturing process. AI predicts machinery breakdown and supports smart automation.

- For instance, Commercial Metals Company uses AI to inspect defects in steel rebar, optimize the production process, and ensure the quality of products.

Trade Analysis of U.S. Steel Rebar Market: Import & Export Statistics

- The United States exported 359 shipments of steel rebar.(Source: volza.com)

- The United States imported 3044 shipments of steel rebar.(Source: volza.com )

- Aldarra Overseas Group Inc. is the leading importer of steel rebar in the United States. (Source: volza.com)

U.S. Steel Rebar Market Value Chain Analysis

- Feedstock Procurement : Feedstock procurement involves the sourcing of raw materials like metallurgical coal, recycled steel, iron ore, and limestone.

- Key Player: Nucor Corporation, Steel Dynamics, Inc., OmniSource Corporation, Sims Metal Management

- Chemical Synthesis and Processing : The chemical synthesis and processing involve methods like smelting, steel refining, alloying, thermomechanical treatment, anti-corrosion treatments, and rebaring chemicals.

- Key Players: Gerdau, Commercial Metals Company, Cleveland-Cliffs Inc., Nucor Corporation

- Quality Testing and Certification : The quality testing involves testing of properties like bend test, elongation test, tensile test, impact test, corrosion test, microstructure test, & visual inspection, and certification includes ASTM standards & CRSI certifications.

What are the Types of Steel Rebar?

| Types | Description | Applications |

| Carbon Steel Rebar | The type of rebar made up of carbon & iron to offer tensile strength to concrete structures in construction projects. |

|

| Deformed Rebar | The ribbed steel bar consists of surface projections like indentations, ribs, or lugs to be used in concrete structures. |

|

| Mild Steel Rebar | The low-carbon steel rebar is used in masonry and concrete structures. |

|

Segmental Insights

Product Type Insights

Why Deformed Steel Rebar Segment Dominates the U.S. Steel Rebar Market?

The deformed steel rebar segment dominated the U.S. steel rebar market with a 70.65% share in 2024. The growing commercial and residential construction activities increase the adoption of deformed steel rebar. The increasing construction of taller buildings and the development of complex infrastructure projects require deformed steel rebar. They offer superior bonding and longer service life. The growing development of large-scale construction projects and modern construction standards requires deformed steel rebar, driving the overall market growth.

The mild steel rebar segment is the fastest-growing in the market during the forecast period. The growing investment in the development of infrastructure projects like public transit, highways, and bridges increases demand for mild steel rebar. The development of data centers and new housing projects requires mild steel rebar. It helps in strengthening concrete structures and offers high strength. The growing repair of existing infrastructure requires mild steel rebar, supporting the overall growth of the market.

Coating Type Insights

How did Plain Carbon Steel Segment Hold the Largest Share in the U.S. Steel Rebar Market?

The plain carbon steel segment held the largest revenue share of 50% in the U.S. steel rebar market in 2024. The development of large-scale projects and the rise in construction activities increase demand for plain carbon steel. The low cost and high availability of carbon steel help the market growth. The strong focus on sustainable construction practices and the focus on high tensile strength increase the adoption of carbon steel, driving the overall growth of the market.

The epoxy coated segment is experiencing the fastest growth in the market during the forecast period. The high adoption of corrosion-resistant materials and focus on extending the lifespan of structures increases the adoption of epoxy coated. The high investment in the development of transportation projects like highways & bridges increases demand for epoxy coated. The development of sustainable construction and modernization of infrastructure projects requires epoxy coated, supporting the overall growth of the market.

Process Type Insights

Why Basic Oxygen Furnace Segment Dominating the U.S. Steel Rebar Market?

The basic oxygen furnace (BOF) segment dominated the market with a 69.28% share in 2024. The availability of raw material and the high production volume of steel rebar increase demand for BOF. The strong focus on lowering carbon emissions and the adoption of energy-intensive processes increase demand for BOF. The cost-effectiveness and development of consistent quality steel rebar require BOF, driving the overall growth of the market.

The electric arc furnace (EAF) segment is the fastest-growing in the market during the forecast period. The lower capital investment and focus on lowering greenhouse gas emissions increase demand for EAF. The presence of abundant scrap steel and the growing demand for rebar increase the adoption of EAF. The growing steel rebar integrated production and stricter environmental regulations increase the adoption of EOF, supporting the overall market growth.

Application Insights

Which Application Held the Largest Share in the U.S. Steel Rebar Market?

The infrastructure segment held the largest revenue share of 67.3% in the U.S. steel rebar market in 2024. The high investment in the development of infrastructure projects like public transit, roads, and bridges increases demand for steel rebar. The growing modernization of infrastructure and aging infrastructure require steel rebar. The growing development of large-scale public projects and strong government support for infrastructure development require steel rebar, driving the overall market growth.

The residential buildings segment is experiencing the fastest growth in the market during the forecast period. The rapid urbanization and growing development of new housing projects increase demand for steel rebar. The strong government support for the development of new residential projects and the rise in multi-housing projects increase demand for steel rebar. The stringent building codes and high investment in affordable housing increase demand for steel rebar, supporting the overall market growth.

Distribution Channel Insights

How the Direct Sales Segment Dominated the U.S. Steel Rebar Market?

The direct sales segment dominated the market with a 60% share in 2024. The growing demand for high-quality products and the focus on just-in-time delivery increase the adoption of direct sales. The strong focus on better communication and the need for transparency increases demand for direct sales. The strong focus on ensuring a consistent steel rebar supply and control over pricing increases demand for direct sales, driving the overall market growth.

The distributors segment is the fastest-growing in the market during the forecast period. The focus on streamlining supply chain processes and growing demand for services like fabrication, cutting, and bleeding increases the adoption of distributors. The growing need for customization of products and the availability of an exact quantity of rebar require distributors. The focus on navigating complex logistics problems and the high demand for specialized products increases the demand for distributors, supporting the overall market growth.

State-Level Insights

Indiana U.S. Steel Rebar Market Trends

Indiana is a key contributor to the market. The growing development of infrastructure projects like manufacturing facilities, highways, and bridges increases demand for steel rebar. The rise in industrial activities and the development of transportation infrastructure increase the adoption of steel rebar. The leading production capacity and presence of key players like Cleveland-Cliffs Indiana Harbor & Gary Works, drive the overall growth of the market.

Texas U.S. Steel Rebar Market Trends

Texas is growing in the market. The high investment in the development of infrastructure projects like roads, waterways, bridges, and airports increases demand for steel rebar. The growing residential construction activities and the development of corporate buildings increase demand for steel rebar. The strong government support for construction activities and the rise in the development of industrial facilities increase the adoption of steel rebar, supporting the overall market growth.

Recent Developments

- In June 2025, Hybar produces its first steel rebar in Osceola, Arkansas, in a new steel mini-mill. The mill focuses on producing 700,000 metric tons of steel rebar.(Source: www.aist.org)

- In February 2024, the Nucor Board approved $860 mln funding for a new rebar mill. The production capacity of the mill is 650000 tons, and a micro mill is present in the Pacific Northwest.(Source: www.reuters.com)

- In April 2024, Sherwin-Williams launched epoxy coating, Sher-Bar TEC, for rebar. The coating is made up of 30% upcycled materials and lowers carbon emissions. (Source: www.coatingsworld.com )

Top Companies List

- Nucor Corporation: The leading manufacturer of steel products & steel and a major supplier of rebar to support industries like infrastructure, automotive, and construction.

- Gerdau S.A.: The largest manufacturer of steel products like merchant bars, rebar, flat products, wire, special steel products, and drawn products.

- Commercial Metals Company (CMC): The global manufacturer of steel rebar, steel fence posts, & merchant bars and a major recycler of metal & steel products.

- Steel Dynamics, Inc.: The American-based company produces steel & steel products like engineered bars, flat rolled steel, and others, with a significant presence of metal recycling.

- Cleveland-Cliffs Inc.: The largest manufacturer of flat-rolled steel products in North America and a major producer of iron ore pellets to support primarily the automotive industry.

Other Companies List

- ArcelorMittal (U.S. operations)

- EVRAZ North America

- JSW Steel USA

- NLMK USA

- Liberty Steel USA

- Cascade Rolling Mills, Inc.

- Alton Steel (Gerdau/Alton facilities)

- Schnitzer Steel Industries, Inc.

- Vinton Steel, LLC

- Adelphia Metals

- Bushwick Metals (and related fabricators)

- Halton Rebar (regional fabricator)

- Insteel Industries, Inc.

- Hybar LLC

- Leeco Steel, LLC

Segments Covered

By Product Type

- Deformed Steel Rebar

- Grade Fe 415

- Grade Fe 500

- Grade Fe 550Mild Steel Rebar

- Grade Fe 250

- Grade Fe 415

By Coating Type

- Plain Carbon Steel

- ASTM A615

- ASTM A706

- Epoxy Coated

- ASTM A775

- ASTM A934

- Galvanized Steel

By Process Type

- Basic Oxygen Furnace (BOF)

- Integrated Steel Mills

- Blast Furnace–Basic Oxygen Furnace (BF-BOF)

- Electric Arc Furnace (EAF)

- Mini Mills

- Scrap-Based Production

By Application

- Infrastructure

- Roads & Bridges

- Tunnels & Airports

- Dams & Ports

- Residential Buildings

- Low-Rise Housing

- High-Rise Apartments

- Industrial

- Factories & Warehouses

- Power Plants

By Distribution Channel

- Direct Sales

- Distributors