Content

Nitrile Butadiene Rubber Market Size and Forecast 2025 to 2034

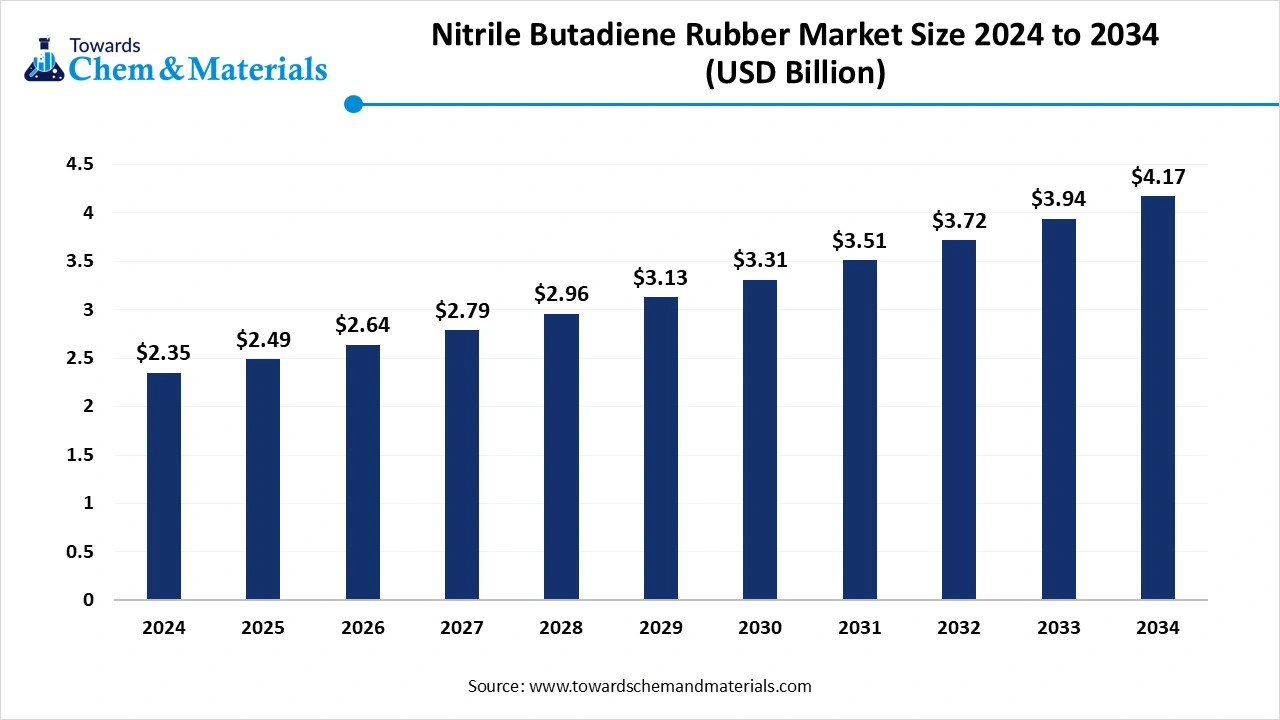

The global nitrile butadiene rubber market size is calculated at USD 2.35 billion in 2024, grew to USD 2.49 billion in 2025, and is projected to reach around USD 4.17 billion by 2034. The market is expanding at a CAGR of 5.90% between 2025 and 2034. The ongoing technological innovations in the NBR technology and the growing demand from oil & gas, automotive, and other industries drive the growth of the market.

Nitrile Butadiene Rubber Market Key Takeaways

- By region, Asia Pacific dominated the nitrile butadiene rubber market in 2024 due to a well-developed manufacturing hub in various industries.

- By region, Europe is growing at the fastest rate in the market during the forecast period due to the growing infrastructure development & industrialization.

- By products, the Seals & O-rings segment dominated the market in 2024 due to rising demand from the automotive sector to prevent leakage.

- By products, the molded & extruded products segment is expected to grow at the fastest rate in the market during the forecast period due to rising demand for gaskets and washers from various industrial applications.

- By application, the automotive segment dominated the nitrile butadiene rubber market with the largest share in 2024 due to the growing adoption of electric vehicles.

- By application, the mechanical engineering segment is expected to grow at the fastest rate in the market during the forecast period due to the increasing demand from various mechanical applications.

Rise Of Nitrile Butadiene Rubber In Automotive and Various Industrial Applications

Nitrile butadiene rubber is a synthetic rubber elastomer and copolymer of butadiene and acrylonitrile. It is also called acrylonitrile butadiene rubber or Buna-N. The polymer, which consists of more nitrile, has high resistance to oil, and the flexibility of the material is low. It possesses strong resistance to acids, oil, fuels, and other chemicals.

These rubbers are great for product that requires oil & gas resistance. It is used as a base for seals, gaskets, hoses, belts, O-rings, and other products. It has a low compression set, excellent abrasion resistance, and tear resistance. It is commonly used for applications that require solvent & oil resistance.

It is used in end-user industries like aeronautical and automotive to manufacture oil & fuel handling grommets, hoses, seals, and self-cleaning fuel tanks. nitrile butadiene rubber sustains in temperature ranges from -40 to 108 degrees Celsius, and these temperatures are ideal for aeronautical applications.

NBR is widely used to manufacture floor mats, sealants, moulded goods, adhesives, sponges, footwear, and expanded foams. Nitrile rubber is used in the healthcare and medical sector in equipment, gloves, and medical tubing due to its lower allergic risk and skin irritation.

The growing demand from the oil & gas industry for gaskets and seals helps in the market growth. The rapid infrastructure development in various countries increases demand for Industrial components and equipment, which fuels demand for nitrile butadiene rubber.

The growing focus on workplace regulatory compliance & safety increases demand for NBR for safety applications.

The increasing technological advancements in various machinery for industrial purposes help in the market growth. Factors like growing demand from various end-user industries, like oil & gas, manufacturing, automotive, construction, & medical, rising demand for energy resources, increasing automobile production, and technological innovation in industrial equipment contribute to the growth of the nitrile butadiene rubber market.

- From November 2023 to October 2024 world exported 34221 shipments of nitrile rubber, and the growth rate compared to the previous 12 months is 47%.

- In 2023, South Korea exported $386 million of Acrylonitrile-butadiene rubber, latex, and the country is the leading exporter.

Nitrile Butadiene Rubber Market Trends

- Rising demand from healthcare and medical applications: The growing demand for examination gloves, disposable labs, and cleaning from the healthcare sector helps in market growth. nitrile butadiene rubber is widely used in manufacturing medical gloves due to its lower infection rate.

- Technological advancement in various sectors: The growing technological advancement in various sectors like construction, automobile, and industrial sectors increases demand for high-performance NBR materials.

- Infrastructure development: The rapid growth in the development and growing investment in various infrastructure projects fuels demand for market. Infrastructure projects increase demand for industrial components & equipment, which directly increases demand for nitrile butadiene rubber. For instance, India's National Infrastructure Pipeline is a plan for infrastructure development that includes various projects like urban development, roads, energy, railways, and many more, which increases demand for NBR materials.

- Expansion of oil & gas in various countries: Growing oil & gas production and exploration fuels demand for durable & reliable NBR, which maintains efficient & safe equipment operations. The rising global demand for energy, transportation, and electricity generation helps in the nitrile butadiene rubber market growth.

Nitrile Butadiene Rubber Market Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 2.49 Billion |

| Expected Size in 2034 | USD 4.17 Billion |

| Growth Rate | CAGR of 5.90% from 2025 to 2034 |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025-2034 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Products, By Application, By Region |

| Key Companies Profiled | NITRIFLEX,ARLANXEO,SIBUR,Zeon Chemicals L.P.,PetroChina Company Ltd,Synthos S.A.,JSR Corporation,LG Chem,KUMHO PETROCHEMICAL,Versalis S.p.A.,AirBoss Of America,Atlantic Gasket Corporation,Precision Associates, Inc.,Anquing Hualan Technology Co., Ltd.,Apcotex Industries Limited,NANTEX Industry Co., Ltd,Chang Rubber,Hanna Rubber Company |

Nitrile Butadiene Rubber Market Opportunity

The Growing Construction Sector Is Surging Demand For Nitrile Butadiene Rubber

A growing civilization fuels demand for various construction projects like commercial, industrial, residential, and infrastructural, which directly increases demand for NBR due to its properties like oil resistance, exceptional durability, and water resistance. Many countries strongly invest in various infrastructure projects like buildings, roads, airports, and bridges, which fuels demand for reliable and durable NBR ber materials. Seals and gaskets are widely used in construction applications like roofing systems, plumbing, and HVAC systems to offer airtight & watertight connections.

The rising demand for sound and thermal insulation in construction increases the utilization of nitrile butadiene rubber. The growing construction activities increase the use of various equipment, which needs NBR.

Government support and initiatives like affordable housing and infrastructure development increase demand for construction that directly fuels demand for NBR. The constant evolution of the construction industry gives rise to new building practices, which increases demand for NBR for various applications.

The growing urbanization, development of new housing, growing renovation, and development of public places create a strong opportunity for the nitrile butadiene rubber market growth.

Nitrile Butadiene Rubber Market Challenge

Raw Material Cost Volatility

Despite several benefits of nitrile butadiene rubber in various industries, volatility in the cost of raw materials restricts the growth of the market. Raw materials required to produce nitrile butadiene rubber are acrylonitrile and butadiene. Butadiene is derived from crude oil, and fluctuating crude oil prices due to geopolitical events limit the growth of the market. The growing demand from various end-user industries is directly responsible for the fluctuation of costs.

- Geopolitical factors like trade restrictions & geopolitical instability hamper the cost & availability of raw materials.

Nitrile Butadiene Rubber Market Regional Insights

Asia Pacific Powerhouse of Nitrile Butadiene Rubber

Asia Pacific dominated the nitrile butadiene rubber market in 2024. The well-established manufacturing hub for various industries like industrial equipment, automotive, and oil & gas, and a high level of manufacturing projects, supports the market growth. The growing expansion of the automotive sector in the region increases vehicle sales and production, which directly increases demand for NBR.

The growing adoption and expansion of electric vehicles in the region help in the market growth. The growing urbanization and development of infrastructure projects increase demand for construction applications like sealing, gaskets, and many more help in the market growth.

The presence of abundant raw materials and the growing demand for medical & healthcare products like gloves drives the market growth. Furthermore, emerging economies, the presence of key manufacturers, and rising demand from end-user industries like mining, automotive, oil & gas, metallurgy, footwear, and construction contribute to the market growth.

China’s Dominance Over The Market

China holds the largest share of the nitrile butadiene rubber market. The major manufacturing hub and rapid growth in the industrial equipment sector drive the growth of the market. The well-established chemical industry processes and produces NBR, which helps in market growth. The rapid expansion of the automotive sector, growing production & adoption of electric vehicles, and focus on modernization fuel demand for NBR-based products.

The strong government policies encourage the adoption of NBR products in various sectors, which increases demand for NBR. The growing population and increasing construction activities help in the market growth. Additionally, a well-established supply chain for global & domestic distribution promotes the overall growth of the market.

Rapid Growth Of Nitrile Butadiene Rubber In India

India is significantly growing in the nitrile butadiene rubber market. The rapid growth in the automotive sector increases demand for NBR based components like hoses, seals, and gaskets, which promotes the growth of the market.

The growing shift towards electric vehicles increases demand for high-performance nitrile butadiene rubber materials. The strong government support and initiative in encouraging manufacturing and investment in industrial & infrastructure development help in the market growth.

The growing medical and healthcare sector increases demand for protective, cleaning, and examination gloves, which directly increases demand for nitrile butadiene rubber. The growing disposable income increased the sales of vehicles, which helps in the market growth. Furthermore, growing construction activities and rising manufacturing promote the overall growth of the market.

- For Instance, the Indian government initiative Make in India encourages companies to develop and manufacture products in India and provides investment for manufacturing.

- India exported 28999 shipments of nitrile rubber.

- In 2023, India exported $3.53M of Acrylonitrile-butadiene rubber, except latex.

Europe’s Emerging Growth In Nitrile Butadiene Rubber

Europe experiences the fastest growth in the market during the forecast period. The growing investments in infrastructure projects and rapid industrialization help in the growth of the market. The rise of electric vehicles and the growing automotive industry increases demand for nitrile butadiene rubber-based products like hoses, gaskets, and other components. Innovations in NBR processes and the development of new formulations fuel the growth of the market.

The rising hygiene and healthcare awareness fuels demand for personal protective equipment and medical supplies, which directly increases demand for NBR. The growing demand for medical supplies from European countries like the United Kingdom, Spain, Germany, and Italy increases demand for the nitrile butadiene rubber. Furthermore, the growing expansion of various industries like aerospace, construction, oil & gas, and medical contributes to the market growth.

Germany Is A Key Pillar In The nitrile butadiene rubber market Growth

Germany is a key contributor to the nitrile butadiene rubber market. The presence advanced and high-quality automotive industry increases demand for NBR to improve the performance of braking systems, engines, and other components. The well-established chemical industry increases manufacturing and production of NBR helps in the growth of the market.

The reliance on precision engineering and rigorous quality standards fuels demand for the nitrile butadiene rubber. The extensive focus on sustainability and the growing production of eco-friendly products drives the market growth. Additionally, strong investment in research and development and well-established supply chains support the overall growth of the market.

Nitrile Butadiene Rubber Market Segmental Insights

Products Insights

The Seals & O-rings segment held the largest share of the nitrile butadiene rubber market in 2024. The growing demand for preventing leaks in automotive components like braking systems, engines, and doors helps in the growth of the market. The growing adoption of advanced driver-assistance systems and electric vehicles increases demand for seals & O-rings to ensure performance. The growing expansion of the oil & gas sector in various regions fuels demand for the seals & O-rings to maintain safety in various processes like refining and drilling.

The growing drug manufacturing and delivery system in the pharmaceutical industry drives the growth of the market. The rapid expansion of infrastructure projects like energy grids and transportation increases demand for seals and O-rings. Furthermore, growing demand from high-tech manufacturing, the aerospace industry, and medical devices contributes to the growth of the market.

The molded & extruded products segment is the fastest growing in the nitrile butadiene rubber market during the forecast period. The growing demand from the construction activities for various applications like pipes, door & window frames, siding, and various components helps in the market growth.

The rapid expansion of the packaging industry increases demand for molded & extruded products. The growing demand from various industrial applications for molded & extruded products such as washers and gaskets, to protect from wear and corrosion, helps in the market growth. Additionally, rising industrialization in various regions increases demand for molded & extruded products, and growing demand from various industries supports the growth of the market.

Application Insights

The automotive segment dominated the nitrile butadiene rubber market in 2024. The growing demand for extensive resistance to chemicals, oil, and fuels in automotive applications helps in the market growth. The growing production of vehicles and other equipment increases demand for the nitrile butadiene rubber-based components. The growing demand for replacement of vehicle components and parts supports the growth of the market.

The growing production of automotive components like engine mounts, gaskets, seals, and hoses increases demand for NBR. The growing demand for damping & sealing in modern vehicles fuels demand for NBR emissions and enhance fuel efficiency. The rapid expansion of electric vehicles fuels demand for NBR, helping in the market growth. Furthermore, increased sales of vehicles, increasing disposable income, and growing demand for environmentally friendly vehicles contribute to the overall growth of the market.

The mechanical engineering segment experiences the fastest growth in the nitrile butadiene rubber market during the forecast period. The increasing infrastructure projects and civilization increase demand for robust components, which helps in the market growth. The growing demand from various mechanical systems, like those in infrastructure project development, vehicles, and industrial applications, helps in the market growth.

In mechanical engineering, seals & gaskets made up of NBR are widely used in pneumatic systems, hydraulic systems, and other mechanical systems. Technological advancement and research in NBR help to create new application that drives the market growth of mechanical engineering. Furthermore, rising demand from various mechanical engineering applications supports the growth of the market.

Recent Developments in Nitrile Butadiene Rubber Market

Bridgestone

- Contribution: In November 2024, Bridgestone is working on developing bio-based butadiene to produce rubber. The United States is focusing on sustainable production to reduce carbon emissions. The company has received USD 9.3 million in federal funding for researching a method for producing bio-based butadiene. The research is going to take place in Akron, Ohio, and they are converting ethanol into butadiene. Bridgestone has partnered with Pacific Northwest National Laboratory to ensure the feasibility of the method. This method reduces carbon emissions by 85% and lowers greenhouse gas emissions.

Ansell

- Launch: In October 2024, Ansell launched new chemical resistance AlphaTec 53-002 and 53-003 gloves. These gloves are useful for liquid and advanced chemical protection. The new gloves are manufactured using MICROCHEM technology and are a single solution for multiple chemical hazard environments. These gloves are free from anti-static, latex, and silicone. AlphaTec 53-002 has a doffing and donning layer for easy use. AlphaTec 53-003 includes a nylon liner for improving comfort during sweat management and use.

Sybron

- Launch: In November 2024, Sybron launched biodegradable nitrile single-use gloves. These gloves are made for the FM, education, hospitality, construction & utility, automobile, janitorial & cleaning, food manufacturing, and healthcare sectors. They are easily disposed of in general waste, and they are powder-free. Gloves are available in two colors, blue and black, and four sizes.

Nitrile Butadiene Rubber Market Top Companies List

- NITRIFLEX

- ARLANXEO

- SIBUR

- Zeon Chemicals L.P.

- PetroChina Company Ltd

- Synthos S.A.

- JSR Corporation

- LG Chem

- KUMHO PETROCHEMICAL

- Versalis S.p.A.

- AirBoss Of America

- Atlantic Gasket Corporation

- Precision Associates, Inc.

- Anquing Hualan Technology Co., Ltd.

- Apcotex Industries Limited

- NANTEX Industry Co., Ltd

- Chang Rubber

- Hanna Rubber Company

Segments Covered in the Report

By Products

- Seals & O-Rings

- Molded & Extruded Products

- Hoses

- Belts

- Cables

- Rubber Compounds

- Adhesives & Sealants

- Gloves

- Foamed Products

- Others

By Application

- Automotive

- Mechanical Engineering

- Oil & Gas

- Metallurgy & Mining

- Construction

- Medical

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East & Africa

- South Africa

- UAE

- Saudi Arabia

- Kuwait