Content

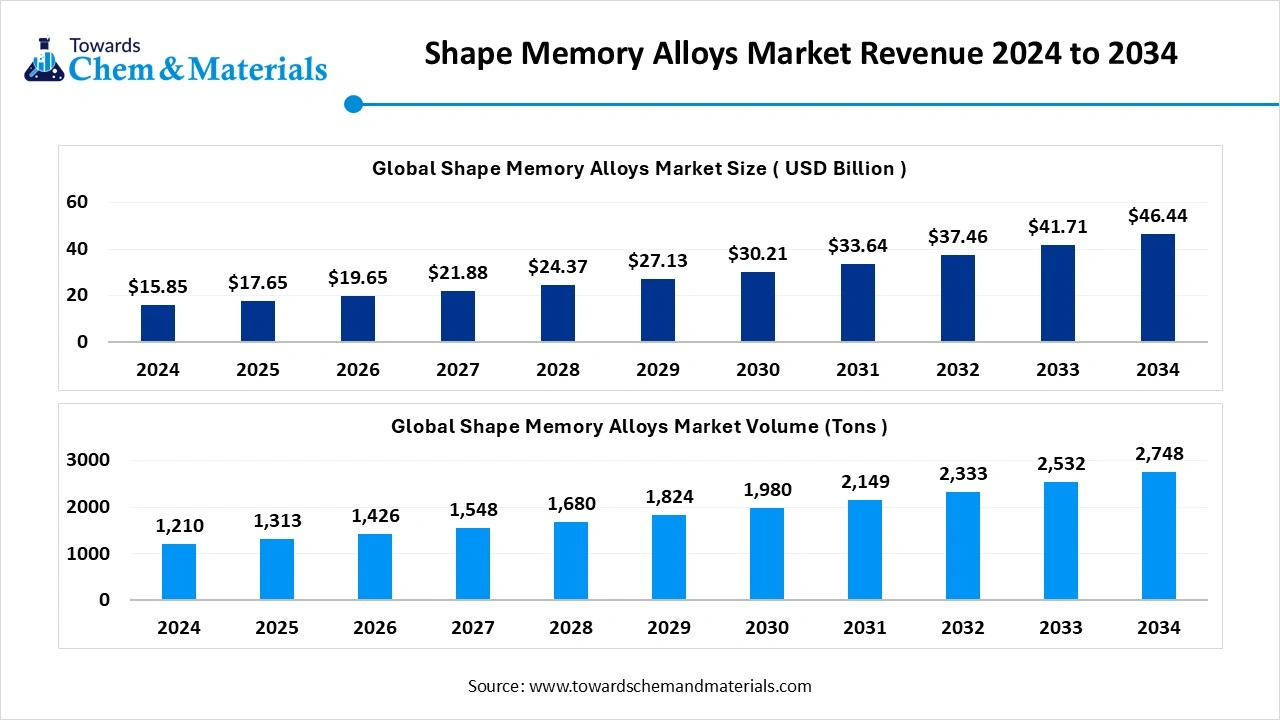

Shape Memory Alloys Market Volume to Reach 2,748 Mn Tons by 2034

The global shape memory alloys market volume is expected to produce approximately 1,313 million tons in 2025, with a forecasted increase to 2,748 million tons by 2034, growing at a CAGR of 11.35% from 2025 to 2034.

The global shape memory alloys market size was valued at USD 15.85 billion in 2024, grew to USD 17.65 billion in 2025, and is expected to hit around USD 46.44 billion by 2034, growing at a compound annual growth rate (CAGR) of 11.35% over the forecast period from 2025 to 2034. Increasing demand of high strength, elastic, and fatigue resistance material in biomedical, aerospace, and automotive industries contribute to market expansion of shape memory alloys.

Key Takeaways

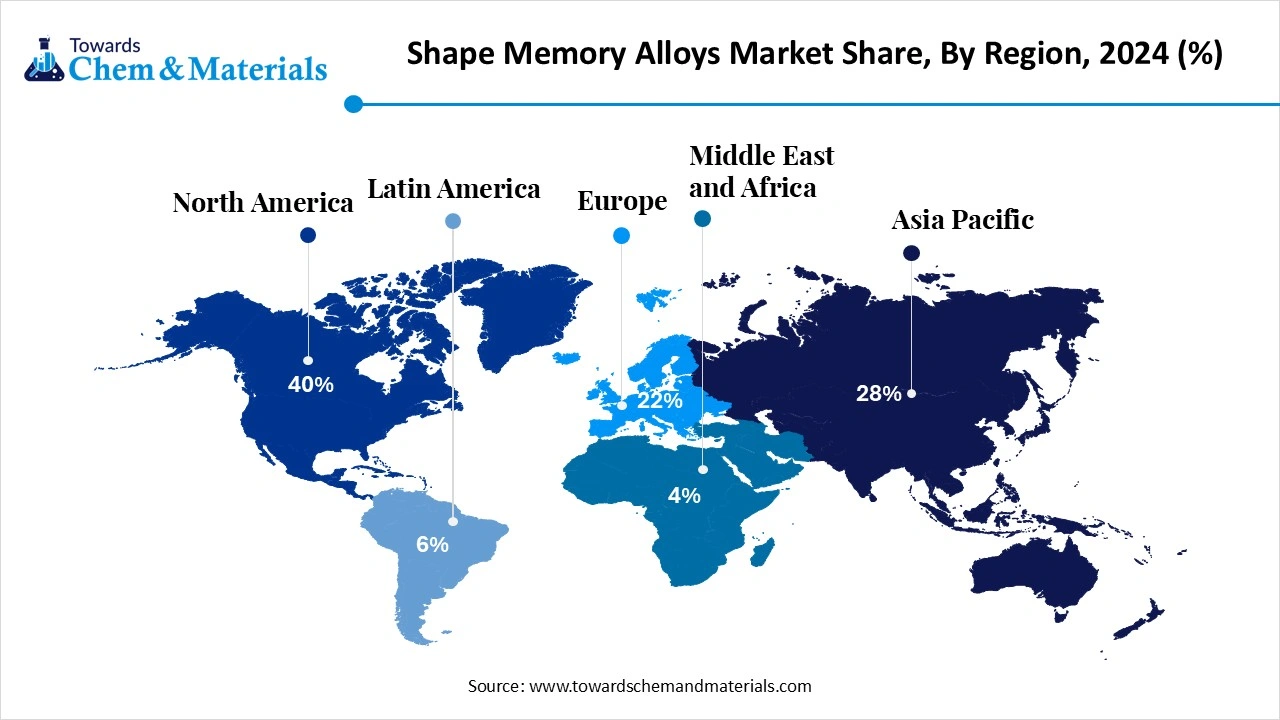

- The North America market held the largest share of 40% of the global market in 2024.

- By region, Asia Pacific expects significant growth in the market during the forecast

- By product, nickel-titanium alloys (nitinol) segment dominated the shape memory alloys market in 2024, due to its super elasticity, biocompatibility, and corrosion resistance properties.

- By product, copper-based alloys segment observed to grow at the fastest rate during the forecast period, attributed to their lower cost and good mechanical properties including thermal conductivity and super elasticity.

- By end use, biomedical segment held the dominating share of shape memory alloys market in 2024, due to wide range of applications in medical devices, and the ongoing advancements in the healthcare industry.

- By application, automotive segment observed to grow at the fastest rate during the forecast period due to increasing demand of lightweight construction, fuel efficiency, and enhanced safety features for high-performance and advanced vehicles

Booming Automotive, Biomedical, and Aerospace Industry Demands High Strength and Fatigue Resistance Material for Various Applications

Shape-memory alloy is the alloy that has ability to return the pre deformed shape when it is heated. Due to elasticity, high strength and fatigue resistance material it is used in different industrial applications such as, including medical, automotive, and aerospace. It is very lighter than traditional materials like steel or titanium which can reduce overall weight of vehicle and aircraft.

In automotive industry increased demand of shape memory alloy for various functions like seat belt adjustment, soft-close mechanisms, and adaptive grille shutters are driving the market. It is also used in aircraft wings to adjust their rigidity and reduce vibration and noise during the landing contributing to growth of market. New advancement of shape memory alloys with the two-way shape memory effect are being developed, allows changing the shape solely through temperature variation without need of any external stresses.

Market Trends

- Unique properties including high strength, shape memory and super elasticity increasing demand of shape memory alloy in biomedical and aerospace industries. In biomedical shape memory alloys are also used in endoscope, guide wires, and clamping system for dentofacial surgery. It shows wide range of application in aerospace by using it in actuators and sensors.

- It has super elasticity which withstands high deformation without permanent damage making them ideal for application which requires high strain and flexibility. Various researches on biodegradable shape memory alloys, the use of additive manufacturing for creating intricate designs for devices like stents, and the development of NiTi showing market oppournities in future

- Due to super elasticity and shape memory affect the shape memory alloys are used in robotics for various applications including robotic hand, wearable devices and soft robotics.

- It is also used in soft actuators using SMA wires for flexible and adoptable robots. Various researches focusing on improving actuation speed and fatigue life through advancement of material and control system may contribute to the growth of the shape memory alloys market.

- Various researches focusing on shape memory alloy with enhanced shape memory effect, super plasticity and actuation capabilities drive the market. New fabrication method like additive manufacturing for complex geometries and functional components from shape memory alloys are also showing the opportunities for shape memory alloys market.

Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 17.65 Billion |

| Expected Size by 2034 | USD 46.44 Billion |

| Growth Rate from 2025 to 2034 | CAGR 11.35% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Dominant Region | North America |

| Segment Covered | By Product, By End-use, By Region |

| Key Companies Profiled | Nippon Seisen Co., Ltd., SAES Group, Johnson Matthey, ATI, Fort Wayne Metals Research Products Corp, Furukawa Electric Co., Ltd. |

Market Opportunity

Rising Demand From Biomedical, Automotive and Aerospace Industries

Shape memory alloys can return the specific shape when heated so it allows creation of devices which can expand inside the body, like stents. Due to biocompatibility, it can safely implant in the body without cause causing any adverse reaction. Due to unique properties of shape memory alloy, it is used in wide range of application including cardiovascular, orthopedic, neurological, and dental. It also used brakes, clutches, and steering systems, as well as sensors for monitoring vehicle health and performance. So, increasing demand from various industries may drive the shape memory alloys market in future.

Growing Demand for Smart Materials

Increasing demand of shape memory alloys in smart material including consumer electronics, wearable technology and medical devices are showing significant market opportunities. The need of compact, flexible and durable component in smart phones and other electronic gadgets drives the market. It can be used in antennas, vibration reduction systems, actuators, and more, improving functionality which may drive future shape memory alloys market growth.

Market Challenges

High Cost Of SMA-Based Devices

Shape material alloys based devices come at higher prices as compared to common material like steel and copper. It involves the complex manufacturing process which requires high raw material and high labor cost. High cost of materials such as titanium, nickel, aluminum, and copper, are expensive and their prices are continuously increasing.

- Additionally, high cost of shape material alloys in medical devices can restrict to use the patient with low budget. Although this material offers advantages but the material with low cost including certion type of plastic may limit the shape memory alloys market.

Regional Insights

North America Shape Memory Alloys Market Size, Industry Report 2034

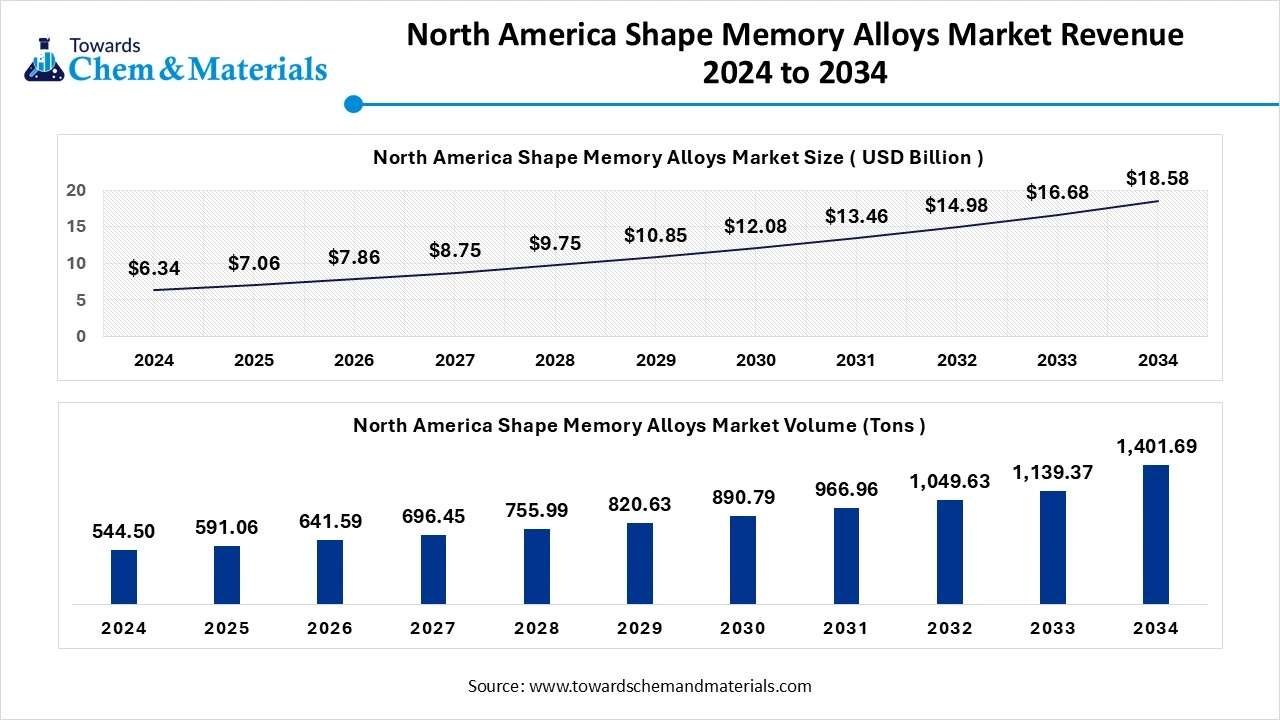

The North America shape memory alloys market volume is estimated at 591.06 million tons in 2025, and is expected to reach 1,401 million tons by 2034, at a CAGR of 9.92% during the forecast period (2025-2034).

The north america shape memory alloys market size was valued at USD 6.34 billion in 2024 and is expected to surpass around USD 18.58 billion by 2034, expanding at a compound annual growth rate (CAGR) of 6.82% over the forecast period from 2025 to 2034. North America dominated shape memory alloys market in 2024.

Due to strong industrial base, technological advancement and high demand from various sectors like aerospace, healthcare, and automotive driving the market in this region. North America is a hub of research and development which is driving the new advancement in shape memory alloy material and application.

In this region, the expanded aerospace and medical sector utilizes this material for wide range of application. Increased manufacturing and supplying of shape memory alloys in this region contribute to market growth. Additionally various companies are investing in expanding production capacity to meet the increased demand

The United States is a major investor and driver of innovation in the shape memory alloys (SMA) market. Various technological advancement , R& D investment and growing demand from various industries driving the market in this countries U.S. market is expected to continue expanding, particularly in sectors like aerospace, automotive, and healthcare which may drive the market in future.

Asia Pacific is showing significant growth in shape memory alloys market in 2024. Rapidly growing industrialization: technological advancement and demand across various industries contribute to market growth in this region. The automotive, aerospace, healthcare and electronic sector is rapidly increasing demand of shape memory alloys in this region.

The consumers prefer smart material and sustainable solution which propel the market. Significant investment in research and development leading to development of new application and new technologies contribute to increasing demand of shape memory alloy. Due to availability of raw materials and inexpensive labor cost, further driving the demand. Countries like China, Japan, and South Korea are the major contributor in the market growth. Due to strong manufacturing base and focus on innovation, advanced research and development increasing demand of shape memory alloy in these countries.

Segmental Insights

Type Insights

The nickel-titanium alloys (nitinol) segment held the dominating share of the shape memory alloys market in 2024. The strong properties of nickel-titanium alloys including biocompatibility, corrosion resistance, and high mechanical performance increase their demand in the market. This alloy possesses excellent biocompatibility, so it is used in medical implant and orthodontic wires. Due to strong mechanical performance including high strength and fatigue resistance it is used in the aerospace actuator and medical device. The growing healthcare industries increasing use of these alloys in advanced medical devices, drive the market.

The copper-based alloys segment is expected to grow at the fastest rate in the shape memory alloys market during the forecast period. It is a cost effective alternative as compared to the nickel-titanium alloys which increases demand in the market. It has simpler processing units and lower cost base material which increases their demand in the market. While copper-based SMAs may not always have the same performance characteristics as other shape memory alloys, they are suitable for a wide range of applications, including actuation, temperature sensing, and biomedical devices, may drive the market in the future.

Application Insights

The biomedical segment held the dominating share of the shape memory alloys market in 2024. Shape memory alloy is increasingly used in medical devices including stents, surgical instrument, and orthopedic implants due to its biocompatibility and high flexibility .The rising demand for minimal invasive procedure and advancement in technology is driving the market growth.

The rising aging population and increasing prevalence of chronic diseases lead to increased demand of medical implant which increases demand of shape memory alloys in biomedical segment. Increased researches in medical device and surgical instruments drives the growth in biomedical segment. Additionally, the demand for high-quality and life-saving medical equipment, where shape memory alloys play a crucial role, is a major driver of market growth.

The automotive segment is expected to grow at the fastest rate in the market during the forecast period. Due to increasing demand of smart material, lightweight construction, and enhanced safety feature increases demand of shape memory alloy. It is used in various automotive applications, actuators and sensors. It reduces overall weight of vehicle and improving efficiency driving the market growth.

Increasing need of passenger comfort and engine noise demands the shape memory alloy, which may contribute to future market growth. Booming automotive industry is increasingly focusing on developing advanced high-performance vehicles which require innovative materials for enhance safety. Additionally, increasing shift towards electric vehicles demands the shape memory alloys driving the market.

Recent Developments

- Cambridge Mechatronics launch: In July 2023, Cambridge Mechatronics launched the 8-wire Shape Memory Alloy (SMA) actuator designed to enable Autofocus (AF) and Optical Image Stabilisation (OIS) in the new flagship handsets: HUAWEI P60 Pro, HUAWEI P60 Art, and HUAWEI P60.

- Fluid-o-Tech Product Launch: In December 2023, Fluid-o-Tech expanded its focus from magnetic systems to include shape memory alloys and piezo technologies, aiming to develop precision fluidics products.

Top Companies List

- Nippon Seisen Co., Ltd.

- SAES Group

- Johnson Matthey

- ATI

- Fort Wayne Metals Research Products Corp

- Furukawa Electric Co., Ltd.

Segments Covered

By Product

- Nickel-Titanium (Nitinol) Alloys

- Copper-Based Alloys

- Others

By End-use

- Biomedical

- Automotive

- Aerospace & Defense

- Consumer Electronics & Household

- Others

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait