Content

Europe Blow Molded Plastic Market Size and Growth 2025 to 2034

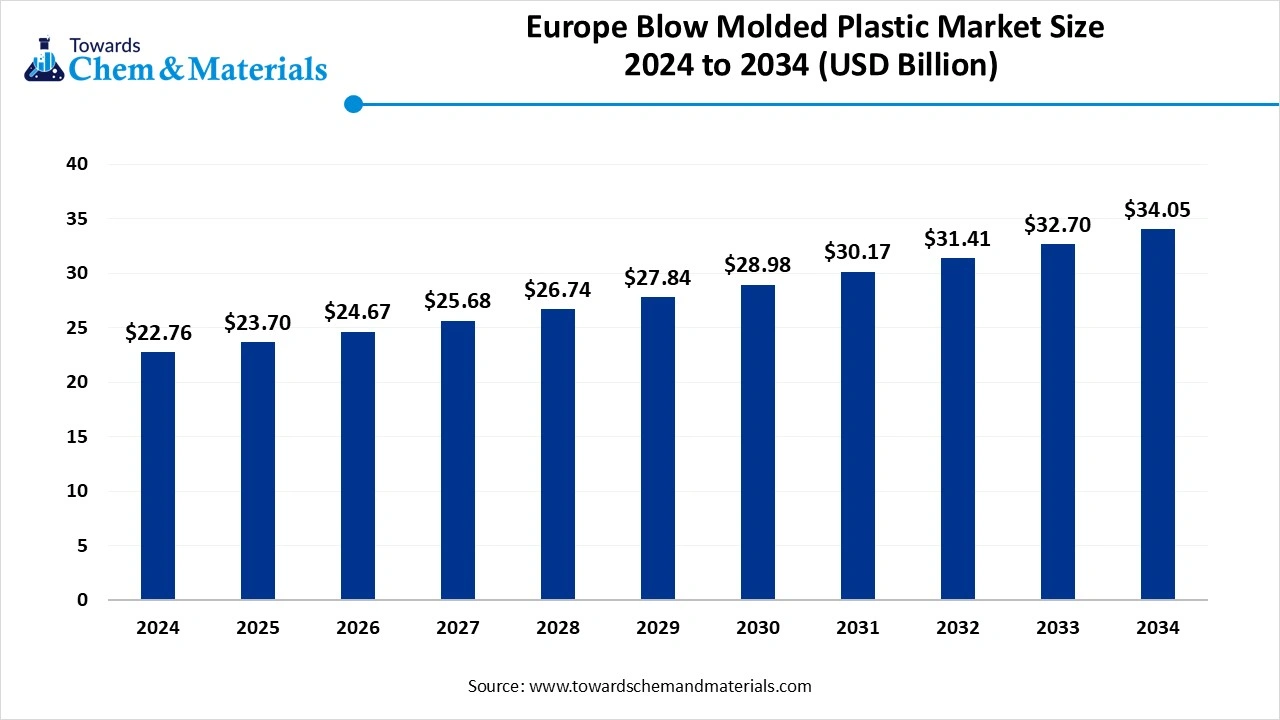

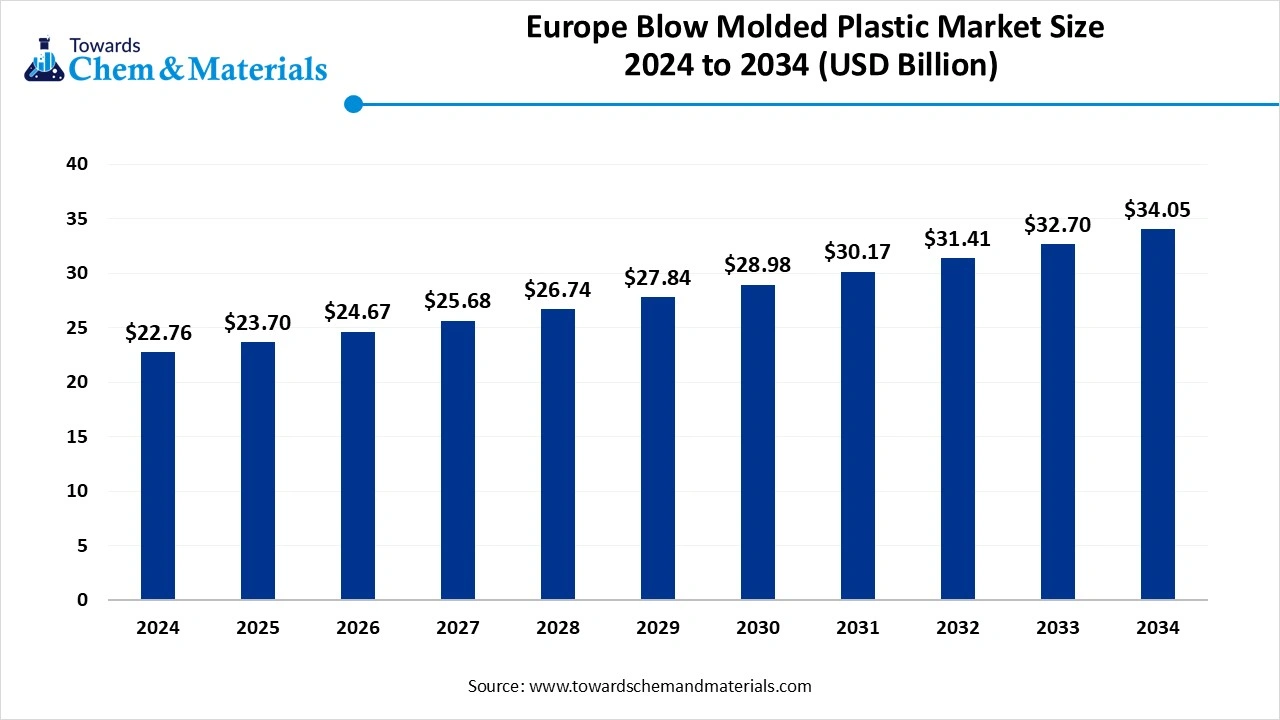

The europe blow molded plastic market size was valued at USD 22.76 billion in 2024. The market is projected to grow from USD 23.7 billion in 2025 to USD 34.05 billion by 2034, exhibiting a CAGR of 4.11% during the forecast period. The increasing need for consumer goods and sustainable packaging initiatives is heavily fueling the industry's growth in the current period.

Key Takeaways

- By technology, the extrusion blow molding segment emerged as the top-performing segment in the market in 2024 due to its perfection in the making of the daily used plastic products.

- By technology, the injection blow molding segment is likely to experience notable growth during the expected period,, akin to advantages like better precision, material control, and surface finish.

- By product, the polyethylene segment led the Europe blow molded plastic market in 2024, owing to unique properties such as flexibility, affordability, and easy molding in recent years.

- By product, the acrylonitrile butadiene styrene segment is projected to grow significantly over the forecast period due to durability, toughness, resistance to heat, and impact.

- By application, the packaging segment dominated the market in 2024, akin it is used in almost every industry-from food and beverages to household and personal care products.

- By application, the automotive and transport segment is expected to grow at a notable rate in the future, the rising need for lightweight, fuel-efficient vehicles.

Market Overview

Consumer Goods to Cars: Blow Molding Shapes Europe’s Industrial Future

The Europe blow molded plastic market is expected to see rapid growth owing to the increasing application of this plastic in major industries such as consumer goods, automotive, and packaging. Moreover, the blow molding it's seen as a crucial part in the production of plastic bottles, containers, and other industrial parts. The European plastic manufacturers are increasingly considering this process akin to its cost effectiveness and suitable for the production of durable plastic products and lightweight materials in the country nowadays. Also, the ongoing implementation of sustainability initiatives has led to recyclable and biobased plastic production in the region in recent years. The modern retail expansion is anticipated to expand plastic production in the coming years, as per industry observation.

What is Driving the Growth of the Blow Molded Plastic Industry in Europe?

The increasing need for recyclable and sustainable packaging is spearheading the industry growth in the region. Several consumers and regulators have been heavily seen in concerning about plastic waste in recent years. Moreover, the governments in the region are actively implementing sustainability policies and regulations for the manufacturing infrastructure. Also, plastic manufacturers are observed as investing heavily in research and development programs to innovate the sustainable production line, and these newly developed products are expected to give a first-mover advantage to the manufacturers in the coming years. Technology innovation and use are also supporting the current industrial growth in the region.

Market Trends

- The increasing popularity of lightweight packaging is driving industrial growth in recent years. This blow-molded plastic production method is considered a crucial method in the production of stronger, thinner, and lighter packaging. Moreover, the e-commerce growth it's severely contributed to the industrial plastic sales in the past few years.

- The increasing focus on branding and customization is contributing to market growth in the current Europe blow molded plastic market. Several companies are seen in creating unique and attractive packaging lineups to develop greater product appealing products while increasing the use of plastics.

- The sudden adoption of biobased plastic for the blow molding process has increased the market potential in recent years. The European government is increasingly cutting off petroleum-based plastic products in favor of eco-friendly plastics, which are recyclable and produced from natural resources.

Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 23.7 Billion |

| Expected Size by 2034 | USD 34.05 Billion |

| Growth Rate from 2025 to 2034 | CAGR 4.11% |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025 - 2034 |

| Segment Covered | By Technology Type, By Product, By Application, By Point of Usage, By Country |

| Key Companies Profiled | Agri-Industrial Plastics, ALPLA-Werke Alwin Lehner GmbH & Co KG, APEX Plastics, Berry Global, Inc., Comar, LLC, Creative Blow Mold Tooling, Custom-Pak, Dow Inc., Garrtech, Inc., Gemini Group, Inc., HTI Plastics, INEOS Group, International Automotive Components, (IAC) Group, LyondellBasell Industries Holdings B.V., Magna International, Inc., Plastipak Holdings, Inc., Rutland Plastics Ltd., The Plastic Forming Company, Inc |

Market Opportunity

Blow Molded Packaging Enters the Digital Era with Smart Features

The development of smart blow-molded packaging is expected to create lucrative opportunities for Europe blow molded plastic market in the coming years. This advanced blow molding packaging can include features such as freshness indicators, QR scanning, and tamper-proof seals. From the observation, smart packaging is continuously gaining consumer attention in Europe in recent times. Also, manufacturers can invest in smart packaging, which is expected to provide them with greater industry attention during the forecast period. Moreover, the rising governmental initiatives towards digitalization are actively encouraging manufacturers to integrate advanced technology into the production line.

Market Challenge

Fluctuating Raw Material Prices Disrupt Manufacturing Momentum

The price volatility of raw materials is projected to hamper the Europe blow molded plastic market growth during the forecast period. The raw materials like plastic raisins include polypropylene, polyethylene, and others are made from petroleum-based based, which seen in under high price fluctuations due to reasons such as geopolitical tensions and others. The small and mid-sized businesses are expected to face these price fluctuation barriers in the coming years, which can create production costs and delays, as per the industry observation for the future period.

Country Analysis

Germany

Germany dominated the Europe blow molded plastic market owing to its heavy manufacturing base and advanced manufacturing technologies in the present period. Moreover, the presence of major industries such as the packaging, automotive, and consumer goods is contributing to the industry growth in the country. Also, the German manufacturers are seen as putting heavy investment in research and automation, which is anticipated to lead the industry's progress during the forecast period.

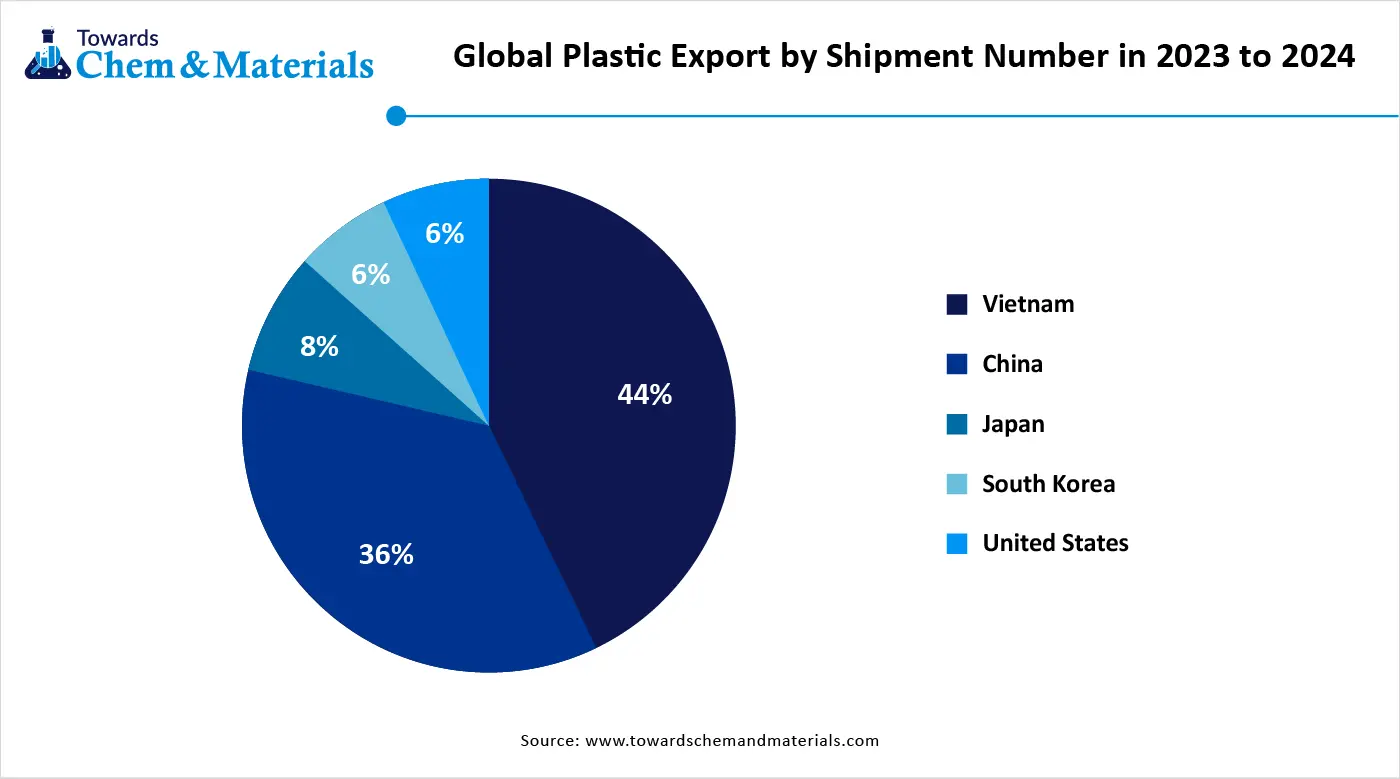

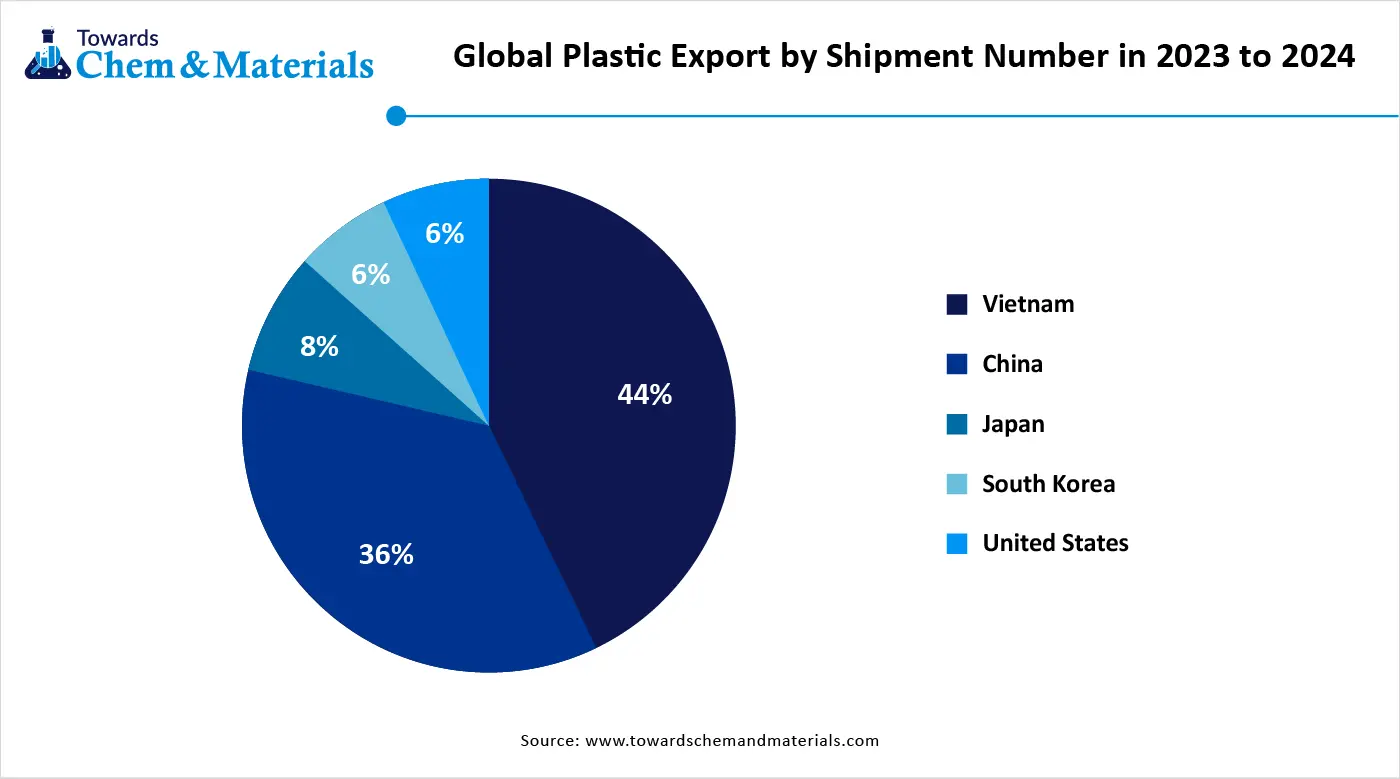

- Product export: Germany recorded 3,116,407 export shipments of plastics from November 2023 to October 2024. This number of shipments is proving that Germany is the leading exporter in the European region.(Source: volza)

Technology Type Insights

How did Extrusion Blow Molding Maintained Its Top Position in the Europe Blow Molded Plastic Market?

The extrusion blow molding segment held the largest share of the market in 2024, due to its perfection in the making of the daily used plastic products such as tanks, containers, and bottles in the current period. Moreover, the unique properties such as cost effectiveness and suitability for high volume production are driving the segment growth in the current period. Also, extrusion molding has a lower-cost maintenance than the other processes, which is gaining major industry attention in recent years.

The injection blow molding segment expects significant growth during the predicted timeframe, owing to advantages like better precision, material control, and surface finish. Also, the increasing need for small and detailed plastic products is expected to provide a huge consumer base to the segment akin as this process is increasingly beneficial in the making of small containers, akin to its precision. By reducing the waste between production, the segment will gain major industry potential in the coming years and is also likely to get governmental support in the region, according to the market environment.

Product Insights

What Makes Polyethylene Segment the Top Contributor to Blow-Molded Plastic Sales?

The polyethylene segment held the dominant share of the Europe blow molded plastic market in 2024 due to unique properties such as flexibility, affordability, and easy molding in recent years. Moreover, industries such as food, packaging, and electronics have been heavily contributing to the growth of the market in recent years. As the advantages like lightweight and safety for the food items, the polyethylene gained significant industry attention in the past few years. Also, by having better chemical resistance, the demand for polyethylene from the industrial and cleaning product packaging is rising continuously.

The acrylonitrile butadiene styrene segment is seen to grow at a expects the significant growth in the market during the forecast period, owing to durability, toughness, resistance to heat, and impact. Moreover, by having these abilities, the major manufacturers such as automakers, electronic casings, and industrial equipment are using acrylonitrile butadiene styrene for their complex applications. Also, the sudden shift towards lightweight and strong components is anticipated to increase the segment growth during the forecast period, as ABS is considered a reliable material.

Application Insights

Is Blow–Molded Packaging Reshaping the Future of European Retail?

The packaging segment held the largest share of the Europe blow molded plastic market in 2023. Packaging dominates the blow molded plastic market in Europe because it's used in almost every industry-from food and beverages to household and personal care products. Blow molding is perfect for producing bottles, containers, and jars in large quantities at low cost. These packaging products are lightweight, durable, and can be easily shaped to fit brand needs. The rise in e-commerce and retail has also increased the demand for strong, attractive, and recyclable packaging. As businesses focus on consumer-friendly and eco-conscious packaging, the use of blow-molded plastics in this segment remains the highest.

The automotive and transport segment expects significant growth in the market during the forecast period due to the rising need for lightweight, fuel-efficient vehicles. Blow molded plastic parts like fuel tanks, ducts, and seat structures help reduce vehicle weight without compromising safety. Europe's automotive sector is also shifting toward electric vehicles (EVs), which need even more lightweight materials. With strict regulations on emissions and increasing production of EVs, carmakers are using more advanced blow-molded plastic parts. This growing demand for durable, lightweight, and cost-effective solutions will make the automotive segment a key market driver in the coming years.

Recent Developments

- In October 2024, The Berry introduced their latest production of PP bottles. These newly launched bottles are fully recyclable and would be considered an alternative to the coloured PET bottles, as per the company's claim. Moreover, the motive behind this launch is the promote sustainability and provide enhanced protection as per the report published by the company. (Source: pharmaceuticalmanufacturer)

- In March 2025, Agilyx is introduced as Plastyx Ltd. This launch aims to supply feedstock for the recycling industries of Europe, as per the company's claim. Also, this newly launched initiative is in collaboration with Plastic Energy founder Carlos Monreal, as per the report published by the company. (Source: packagingeurope)

Top Companies list

- Agri-Industrial Plastics

- ALPLA-Werke Alwin Lehner GmbH & Co KG

- APEX Plastics

- Berry Global, Inc.

- Comar, LLC

- Creative Blow Mold Tooling

- Custom-Pak

- Dow Inc.

- Garrtech, Inc.

- Gemini Group, Inc.

- HTI Plastics

- INEOS Group

- International Automotive Components (IAC) Group

- LyondellBasell Industries Holdings B.V.

- Magna International, Inc.

- Plastipak Holdings, Inc.

- Rutland Plastics Ltd.

- The Plastic Forming Company, Inc

Segment Covered

By Technology Type

- Extrusion Blow Molding

- Injection Blow Molding

- Stretch Blow Molding

- Compound Blow Molding

By Product

- Polypropylene

- Acrylonitrile butadiene styrene (ABS)

- Polyethylene

- Polystyrene

- PVC

- PET

- Others

By Application

- Packaging

- Consumables & Electronics

- Automotive & Transport

- HVAC Ducts

- Air Intake Ducts

- Others

- Building & Construction

- Medical

- Others

By Point of Usage

- Household Industrial Chemical Containers

- Toiletries & Cosmetics and Personal Care & Medical

- Food & Beverage Bottles

- Industrial Containers & Drums

- Pipes, Cables & Insulation

- Automotive & Transportation

By Country

- Germany

- U.K.

- France

- Italy

- Central Europe

- Poland

- Slovakia

- Czech Republic

- Hungary

- Romania

- Former Yugoslavian Countries