Content

Amine Hardener Market Size and Forecast 2025 to 2034

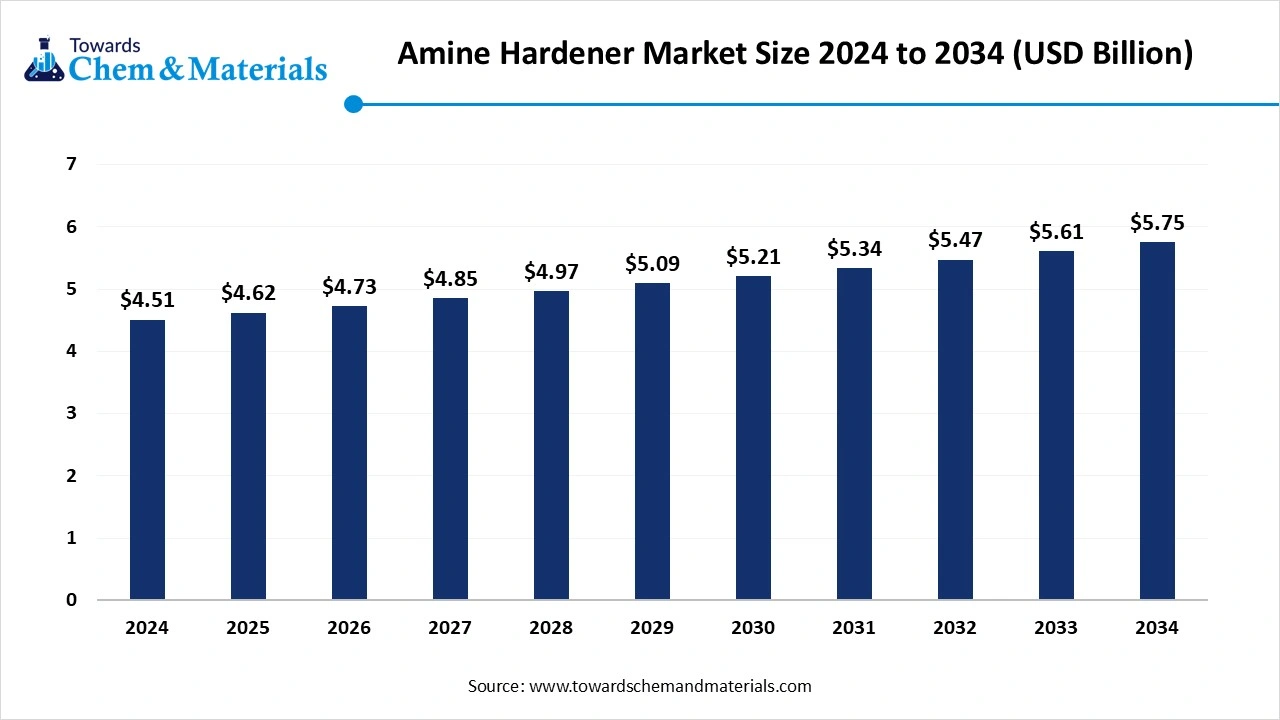

The global amine hardener market size was valued at USD 4.51 billion in 2024 and is estimated to hit around USD 5.75 billion by 2034, growing at a compound annual growth rate (CAGR) of 2.45 % during the forecast period 2025 to 2034. The growing demand for eco-friendly and sustainable solutions and rising construction activities in the region drive the growth of the market.

Amine Hardener Market Key Takeaway

- By region, Asia Pacific dominated the market in 2024. The growth is driven by rapid industrialization, infrastructure growth, and expansion of manufacturing sectors

- By region, North America is anticipated to have significant growth in the market in the forecasted period. Well-established construction, automotive, and aerospace industries in the region drive the growth.

- By application, the adhesives segment dominated the market in 2024. Increasing demand for high-performance bonding solutions for lightweight and hybrid materials drives the growth.

- By application, the coatings segment is anticipated to grow in the forecasted period. Increasing demand for long-lasting protective coatings in infrastructure and heavy-duty applications drives the market.

- By product, the polyamines segment dominated the market in 2024. The cost-effectiveness and strong performance characteristics keep polyamines in high demand

- By product, the aliphatic amines segment is anticipated to grow significantly in the market during the forecasted period. Versatility and reliability make them a popular choice across industries.

- By end use, the automotive segment dominated the market in 2024. The growing demand for lightweight composite materials drives the use of amine hardeners.

- By end use, the construction segment is anticipated to grow in the forecasted period. The demand for higher strength and faster curing solutions drives the growth of the market.

Rising demand for the construction industry: amine hardener market to expand

A hardener is a curing agent that reacts with a resin and forms a crosslinking polymer by using a catalyst, which initiates resin polymerization. Amine hardeners are the most used epoxy resin types, like aliphatic amines, aromatic amines, and cycloaliphatic amines. The amines and acid anhydrides are the most used hardeners. Whereas aliphatic amines react rapidly at room temperature, aromatic amine hardeners impart higher thermal stability and improved chemical resistance. Depending upon the hardener used, the reaction and chemistry of the process change and align.

The growing demand for high-performance epoxy-based coatings and adhesives across various industries such as construction, automotive, and aerospace. They are in high demand due to the excellent properties offered by the hardeners, such as chemical resistance, durability, and mechanical strength, which makes them essential in applications that require long-term structural integrity.

Rapid industrialization and infrastructural development in the emerging economies boost the consumption of the amine hardeners, which results in an increasing demand. The increasing focus on lightweight, high-strength composite materials in the automotive and aerospace sectors further contributes to the growth of the amine hardener market.

Amine Hardener Market Trends

- The growing demand for sustainable and eco-friendly formulations due to growing health concerns increases the demand for low-VOC and bio-based hardeners, which drives the market growth.

- The technological advancement in the development of the amine hardener, such as UV and microwave curing, which helps in the enhancement of thermal stability and emission, helps drive the market.

- The increasing demand for high-performance materials in different sectors for industry-specific hardeners drives the development of specialised amine hardeners.

- The rapid industrialization and infrastructural development in the regions help in the significant growth of the amine hardener market.

Amine Hardener Market Report Scope

| Report Attributes | Details |

| Market Size in 2025 | USD 4.62 Billion |

| Expected Size in 2034 | USD 5.75 Billion |

| Growth Rate | CAGR of 2.45% from 2025 to 2034 |

| Base Year of Estimation | 2024 |

| Forecast Period | 2025-2034 |

| Dominant Region | Asia Pacific |

| Segment Covered | By Application, By Product, By End Use, By Region |

| Key Companies Profiled | Kraton Corporation,Mitsubishi Gas Chemical Company,Elementis,BASF,Olin Corporation,Eastman Chemical Company,Albemarle Corporation,Hexion Specialty Chemicals,Huntsman,AkzoNobel,Hexion,Air Products and Chemicals,DOW,Evonik Industries |

Amine Hardener Market Opportunity

The Growing Emphasis on the Use Of Sustainable and Eco-Friendly Products

The shift towards sustainable and eco-friendly products presents a major opportunity in the amine hardener market. As industries face increasing pressure to reduce environmental impact, the demand for low-VOC, non-toxic, and bio-based hardeners is growing steadily. Manufacturers are capitalizing by developing innovative formulations that meet regulatory standards while maintaining performance.

Waterborne systems and plant-derived raw materials are gaining the attention of consumers, especially in the construction and automotive sectors focused on green building and cleaner production. Companies that prioritize sustainability can not only enhance their brand image but also tap into a fast-expanding market segment driven by environmental responsibility, which results in the growth of the market.

Amine Hardener Market Challenge

The Limited Shelf Life And Complexity in Handling The Sensitive Formulation

A major challenge in the amine hardener market is the limited shelf life and handling complexity of certain formulations. Many amine-based systems are highly reactive, which makes them sensitive to storage conditions and can lead to premature curing or degradation of the material. This requires strict control during transportation and storage, increasing logistical and operational burdens for manufacturers and end users. Additionally, some amine hardeners emit strong odors and may cause skin or respiratory irritation, necessitating the use of protective equipment and specialized handling procedures. These practical limitations can reduce user convenience and reduce adoption in industries seeking simpler, more user-friendly solutions, which hinders the growth of the market.

Amine Hardener Market Regional Insights

Asia Pacific dominated the amine hardener market in 2024. In Asia Pacific, the growth is driven by rapid industrialization, infrastructure growth, and expansion of manufacturing sectors. The construction and automotive industries, particularly in emerging economies, have created strong demand for high-performance epoxy systems. The region also benefits from lower production costs and the presence of several major raw material suppliers. As investment in public infrastructure, commercial real estate, and industrial facilities continues to rise, the need for durable adhesives and coatings increases. Additionally, government initiatives supporting industrial growth and sustainability are further encouraging the adoption of advanced materials, including amine-cured systems, across the region, which drives the growth of the market.

India's Growing Construction Sector and Expansion in the Manufacturing Industry Drive The Growth Of The Market

India represents one of the fastest-growing markets for amine hardeners due to booming construction activity, rising automotive production, and expanding electronics manufacturing. Urbanization and infrastructure development, such as highways, smart cities, and industrial parks, are generating significant demand for epoxy-based adhesives and coatings. Indian manufacturers are increasingly adopting high-performance and durable materials to meet modern engineering and building standards.

Additionally, the country’s focus on Make in India and support for domestic industries is encouraging local production of epoxy systems. As environmental and quality standards continue to evolve, demand for more efficient, customizable amine hardeners is expected to grow steadily in India.

India exported 3 Amine and HSN Code 3908, mostly the export of amine is to France, Bangladesh, and Iran.Globally, the top exporters of Amine and HSN Code 3908 are India, China, and Germany.

North America's Well-Established Construction, Automotive, and Aerospace Industries Grow the Demand For The Market and Help In Expansion.

North America is anticipated to grow significantly in the amine hardener market in the forecasted period. North America holds a significant share in the market, supported by its well-established construction, automotive, and aerospace industries. The region is characterized by early adoption of advanced materials and technologies, driving demand for high-performance epoxy systems.

Strict quality standards and safety regulations encourage the use of reliable and durable curing agents, particularly in infrastructure repair, industrial coatings, and vehicle manufacturing. Additionally, the growing trend toward renovation and modernization of aging infrastructure supports the need for efficient and long-lasting adhesives and coatings. Continuous research and development efforts also contribute to innovations in amine hardener formulations across the region, which drives the growth of the amine hardener market.

The United States' Strong Infrastructure Repair Projects Fuel the Growth of The Market

The United States is a key contributor to the amine hardener market in North America, driven by strong demand from the construction, automotive, and industrial sectors. Infrastructure repair projects, including roads, bridges, and public buildings, are fueling the need for high-performance epoxy adhesives and coatings. The country’s emphasis on durability, safety, and compliance with environmental standards promotes the use of advanced curing systems.

Additionally, the U.S. automotive and aerospace industries rely heavily on amine-cured materials for lightweight components and structural bonding. With steady investment in research, innovation, and sustainable materials, the demand for amine hardeners continues to grow across various applications. 11,598 shipments of hardeners were exported by the United States from October 2023 to September 2024.

Amine Hardener Market Segmental Insights

Application Insights

The adhesives segment dominated the amine hardener market in 2024. Amine hardeners play a critical role in the formulation of epoxy-based adhesives, offering strong mechanical bonding, high chemical resistance, and excellent durability. These adhesives are widely used in construction, automotive, electronics, and aerospace industries where structural integrity is vital. The ability of amine-cured adhesives to withstand harsh conditions, including moisture and heat, makes them ideal for demanding applications.

They also provide fast curing times and strong adhesion to various substrates such as metals, plastics, and composites. As industries increasingly seek high-performance bonding solutions for lightweight and hybrid materials, the demand for amine hardeners in adhesive formulations continues to grow steadily.

The coatings segment expects significant growth in the amine hardener market during the forecast period. Amine hardeners are essential components in epoxy coating systems, valued for their ability to enhance chemical resistance, mechanical strength, and durability. These coatings are widely applied in industrial flooring, marine structures, pipelines, and protective surfaces exposed to harsh environments. Amine-cured coatings provide excellent adhesion and resistance to abrasion, corrosion, and chemicals, making them suitable for both protective and decorative purposes.

Their versatility allows for use in both solvent-based and waterborne systems. With increasing demand for long-lasting protective coatings in infrastructure and heavy-duty applications, the use of amine hardeners in the coatings segment continues to expand across various end-use industries.

Product Insights

The polyamines segment dominated the amine hardener market in 2024. Polyamines are a key type of amine hardeners widely used in epoxy resin systems due to their fast curing, strong adhesion, and superior chemical resistance. They are particularly effective in applications requiring high performance under harsh conditions, such as industrial flooring, marine coatings, and structural adhesives. Polyamines offer good thermal stability and mechanical strength, making them suitable for both ambient and elevated temperature curing processes.

However, they often require precise handling due to their sensitivity to moisture and potential for yellowing. Despite these challenges, their cost-effectiveness and strong performance characteristics keep polyamines in high demand across multiple industrial sectors, which grows demand for the amine hardener market.

The aliphatic amines segment is expected to experience significant growth in the amine hardener market during the forecast period. Aliphatic amines are widely used as curing agents in epoxy systems, offering excellent toughness, chemical resistance, and adhesion. These hardeners are typically employed in coatings, adhesives, and composites where fast curing and mechanical strength are essential. Aliphatic amines cure at room temperature and provide good color stability, although they may be more sensitive to moisture compared to other types.

Their low viscosity and compatibility with various epoxy resins make them easy to formulate and apply. Common applications include protective coatings for concrete and steel, automotive adhesives, and marine finishes. Their versatility and reliability make them a popular choice across industries, which increases the demand for the market.

End Use Insights

The automotive segment dominated the amine hardener market in 2024. In the automotive industry, amine hardeners are crucial for producing high-performance epoxy systems used in adhesives, sealants, coatings, and composites. These materials contribute to vehicle durability, structural strength, and lightweighting, key factors in modern vehicle design.

Amine-cured adhesives are used for bonding various parts, including metal, plastic, and composite components, offering strong, long-lasting joints that can withstand vibration, temperature fluctuations, and chemical exposure. Epoxy coatings with amine hardeners protect vehicle parts from corrosion, wear, and harsh environmental conditions. Additionally, with the rising adoption of electric vehicles and the push for fuel efficiency, demand for lightweight composite materials further drives the use of amine hardeners, which drives the growth.

The construction segment expects significant growth in the amine hardener market during the forecast period. In the construction sector, amine hardeners are widely used in epoxy systems for applications such as concrete repair, flooring, grouts, sealants, and protective coatings. They provide excellent adhesion, chemical resistance, and mechanical strength, which are essential for structural durability and long-term performance.

Epoxy flooring systems cured with amine hardeners are favored in industrial and commercial buildings due to their resistance to heavy loads, abrasion, and chemical spills. They also play a vital role in bonding and sealing applications in bridges, tunnels, and infrastructure projects. As construction projects demand higher strength and faster curing solutions, the use of amine hardener continues to grow.

Amine Hardener Market Recent Developments

Evonik

- Launch: In February 2024, Evonik launched a new range of curing agents, Ancamine 2844, which is a coating agent having a high functional aliphatic amine hardener that offers ultra-fast curing properties even in harsh and changing conditions. The product claims to offer quality, productivity, and protection through coating application.

BASF and Sika

- Launch: In March 2025, BASF and Sika collaborated and developed a new curing agent, an amine building block for curing epoxy resins. This development is especially done for flooring applications like high-gloss and durable flooring. This provides sustainable solutions in the construction industry.

Amine Hardener Market Top Companies List

- Kraton Corporation

- Mitsubishi Gas Chemical Company

- Elementis

- BASF

- Olin Corporation

- Eastman Chemical Company

- Albemarle Corporation

- Hexion Specialty Chemicals

- Huntsman

- AkzoNobel

- Hexion

- Air Products and Chemicals

- DOW

- Evonik Industries

Segments Covered in the Report

By Application

- Adhesives

- Coatings

- Composites

- Construction

- Textiles

By Product

- Aliphatic Amines

- Aromatic Amines

- Cycloaliphatic Amines

- Polyamines

- Piperazines

By End Use

- Consumer Goods

- Industrial

- Construction

- Electronics

- Automotive

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait